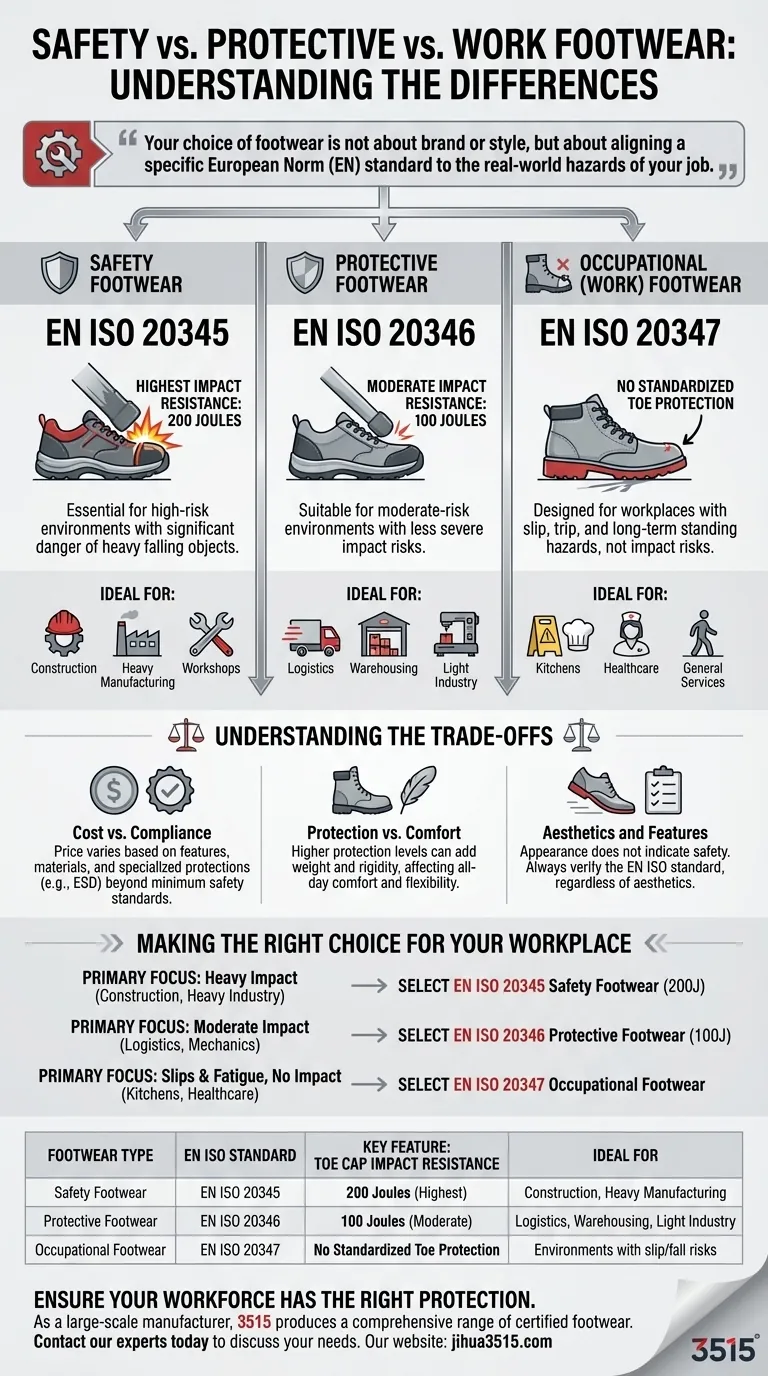

The fundamental difference between safety, protective, and work shoes is the level of toe protection they are certified to provide. Safety shoes offer the highest impact resistance (200 joules), protective shoes offer a moderate level (100 joules), and work shoes offer no standardized impact protection for the toe.

Your choice of footwear is not about brand or style, but about aligning a specific European Norm (EN) standard to the real-world hazards of your job. Understanding these standards is the only way to ensure you have the correct level of protection.

A Breakdown of the Core Standards

Each category of footwear corresponds to a specific EN ISO standard, which certifies its protective capabilities. A worksite's risk assessment should determine which standard is required.

Safety Footwear (EN ISO 20345)

This is the highest standard for protective footwear. The key feature of shoes certified under EN ISO 20345 is a toe cap that withstands 200 joules of impact energy.

This level of protection is essential in high-risk environments like construction sites, heavy manufacturing, and workshops where the danger of heavy objects falling or rolling onto the foot is significant.

Protective Footwear (EN ISO 20346)

This standard represents a step down in protection, designed for moderate-risk environments. Shoes certified under EN ISO 20346 have a toe cap that withstands 100 joules of impact.

This footwear is suitable for jobs in areas like logistics, warehousing, or light industry, where the risk of impact is present but less severe than in heavy-duty settings.

Occupational (Work) Footwear (EN ISO 20347)

This category is often misunderstood. Footwear certified under EN ISO 20347 has no protective toe cap and offers no guaranteed impact resistance.

Instead, these shoes are designed for workplaces where slips, trips, and long-term standing are the primary hazards. They often feature enhanced slip resistance, antistatic properties, or ergonomic support but are not intended for environments with a risk of falling objects.

Understanding the Trade-offs

Choosing the right shoe involves balancing mandatory safety requirements with other practical factors. The EN ISO standard is the non-negotiable starting point.

Cost vs. Compliance

All certified shoes meet the minimum safety requirements for their standard. A basic pair of S1 safety shoes might be significantly cheaper than a more advanced pair.

The price difference often comes from additional features, superior materials, or specialized protections like Electrostatic Discharge (ESD) compliance, which can double the cost.

Protection vs. Comfort

Higher levels of protection, especially with traditional steel toe caps, can add weight and reduce flexibility.

While modern composite materials have improved this, there is often a direct trade-off between the shoe's protective rigidity and its all-day comfort and wearability.

Aesthetics and Additional Features

Higher-priced options often provide better aesthetics, looking more like casual trainers or formal shoes.

However, the look of the shoe is irrelevant to its safety rating. Always verify the specific EN ISO standard printed on the shoe's tongue or lining, regardless of its appearance.

Making the Right Choice for Your Workplace

Your decision should be driven solely by the risks present in your work environment.

- If your primary focus is protection from heavy impact (construction, heavy industry): You must select EN ISO 20345 Safety Footwear with its 200-joule toe cap.

- If your primary focus is protection from moderate impact (logistics, mechanics): EN ISO 20346 Protective Footwear with a 100-joule toe cap is the appropriate choice.

- If your primary focus is preventing slips and fatigue with no impact risk (kitchens, healthcare): You need EN ISO 20347 Occupational Footwear, which prioritizes features other than toe protection.

Ultimately, selecting the correct footwear is a critical safety decision that begins with a clear understanding of the standards.

Summary Table:

| Footwear Type | EN ISO Standard | Key Feature: Toe Cap Impact Resistance | Ideal For |

|---|---|---|---|

| Safety Footwear | EN ISO 20345 | 200 Joules (Highest) | Construction, Heavy Manufacturing |

| Protective Footwear | EN ISO 20346 | 100 Joules (Moderate) | Logistics, Warehousing, Light Industry |

| Occupational Footwear | EN ISO 20347 | No Standardized Toe Protection | Environments with slip/fall risks, no impact hazards |

Ensure your workforce has the right protection. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety, protective, and occupational footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the precise EN ISO standard required for your workplace hazards. Contact our experts today to discuss your specific needs and receive a tailored solution.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Premium Wheat Nubuck Safety Shoes for Bulk Distribution

People Also Ask

- What are the main categories used to classify work shoes? Find Your Perfect Safety Footwear

- What role does professional-grade protective footwear play in mitigating exposure to harmful substances? Safe Barriers

- What role do professional safety shoes play in mitigating risks during aviation maintenance on scaffolding? Ensure Worker Safety & Stability

- How do slip-resistant outsoles in safety shoes mitigate the risk of physical imbalance? Boost Grip & Prevent Falls

- Do yearly updates to ASTM safety standards affect the core protection thresholds? Understanding the Stable Safety Benchmark

- What are the advantages of composite safety toes over steel toes? A Guide to Lighter, Safer Work Boots

- What are the technical advantages of using puncture-resistant composite midsoles in safety footwear? | Lightweight Power

- What are the advantages of composite toe shoes? Achieve Superior Safety and Comfort