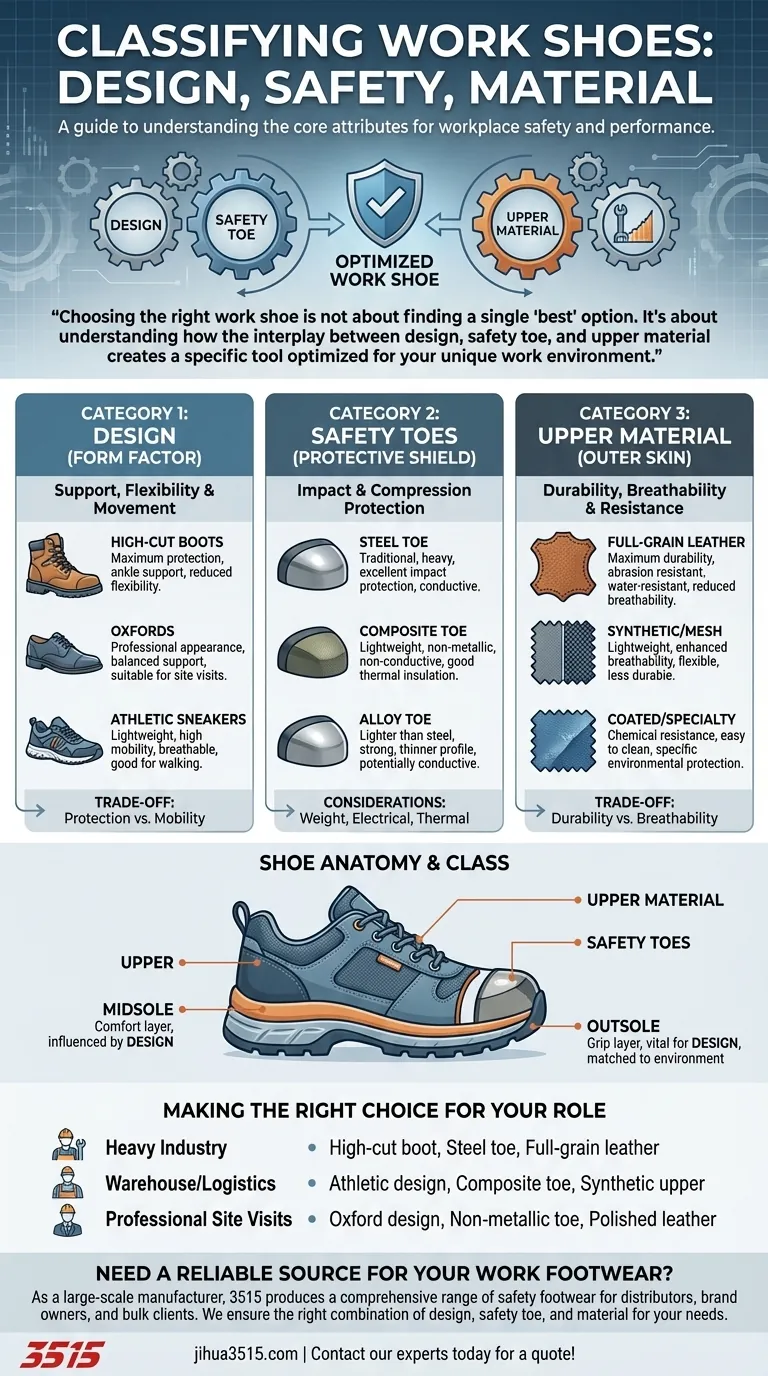

The primary classification system for work shoes revolves around three core attributes: their design, the type of safety toe they incorporate, and the material of their upper construction. This framework moves beyond simple aesthetics to categorize footwear based on functional performance, allowing you to match a shoe's features directly to your specific workplace hazards and daily tasks.

Choosing the right work shoe is not about finding a single "best" option. It's about understanding how the interplay between design, safety toe, and upper material creates a specific tool optimized for your unique work environment and safety requirements.

Deconstructing the Classification Framework

To make an informed decision, you must understand what each category represents and how it impacts your safety and comfort on the job. These three pillars work together to define the shoe's purpose.

Category 1: Design (The Form Factor)

The "Design" of a work shoe refers to its overall shape and style, which directly influences its level of support, flexibility, and suitability for certain tasks.

This category includes everything from traditional high-cut work boots to low-cut oxford styles and even athletic-inspired safety sneakers. The design dictates factors like ankle support and freedom of movement.

Category 2: Safety Toes (The Protective Shield)

The safety toe is the reinforced area at the front of the shoe designed to protect your feet from impact and compression.

This is a critical safety feature, and the type of material used—such as steel, composite, or alloy—determines the toe's weight, electrical conductivity, and thermal insulation.

Category 3: Upper Material (The Outer Skin)

The "Upper" is the part of the shoe that covers the top of your foot. The material used here is a primary classification factor because it defines the shoe's durability, breathability, and resistance to environmental factors like water or chemicals.

Common materials include full-grain leather for maximum durability, or advanced synthetics and mesh for lighter weight and enhanced breathability.

Understanding the Trade-offs

No single work shoe excels in every situation. The classification system helps you navigate the inherent trade-offs between different features to find the optimal balance for your needs.

Protection vs. Mobility

A high-cut boot design made of thick leather offers maximum protection and ankle support. However, this comes at the cost of increased weight and reduced flexibility compared to a low-cut athletic design.

Durability vs. Breathability

A full-grain leather upper is exceptionally resistant to abrasion and wear. The trade-off is often reduced breathability, which can be a concern in hot climates. Synthetic mesh uppers, conversely, offer excellent airflow but may not withstand the same level of abuse.

Material vs. Environment

The choice of upper material and outsole composition is critical for your specific environment. A leather upper might be ideal for construction, while a synthetic, easily cleaned material is better suited for food processing. Likewise, outsoles are rated for slip, oil, and chemical resistance.

How a Shoe's Anatomy Informs Its Class

While not primary classification categories, the other parts of a shoe's construction—the midsole and outsole—are directly influenced by the main three categories.

The Midsole's Role in Comfort

The midsole is the cushioning layer between your foot and the outsole. While its material (like EVA or PU foam) isn't a top-level category, it is a key feature determined by the shoe's Design. An athletic-style shoe will prioritize a cushioned, flexible midsole.

The Outsole's Role in Grip

The outsole is the bottom layer that contacts the ground. Its material (often rubber or TPU) and tread pattern are vital for traction. This feature is a critical component of the overall Design and is selected to match the shoe's intended work environment.

Making the Right Choice for Your Role

Use this classification framework to filter your options based on your job's specific demands.

- If your primary focus is maximum protection in heavy industry: Prioritize a high-cut boot design with a steel toe and a durable, full-grain leather upper.

- If your primary focus is mobility and comfort in a warehouse or logistics setting: Look for an athletic-style design with a lightweight composite toe and a breathable synthetic upper.

- If your primary focus is a professional appearance with certified safety for site visits: Consider an oxford-style design with a non-metallic safety toe and a polished leather upper.

By understanding these core categories, you can move beyond brand names and confidently select the precise footwear engineered for your safety and comfort.

Summary Table:

| Classification Category | Key Function | Common Examples |

|---|---|---|

| Design (Form Factor) | Determines support, flexibility, and movement | High-cut boots, oxfords, athletic sneakers |

| Safety Toe | Protects feet from impact and compression | Steel toe, composite toe, alloy toe |

| Upper Material | Defines durability, breathability, and resistance | Full-grain leather, synthetic, mesh |

Need a Reliable Source for Your Work Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the right combination of design, safety toe, and material for your specific needs.

Let us help you equip your workforce with the right tools.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

People Also Ask

- What is the role of a toecap in safety boots? Ensure Maximum Foot Protection on the Job

- What are the advantages of using leather in safety shoes? Superior Durability & Breathability

- What materials are typically used in safety trainers? A Guide to Protective Footwear Components

- Why are impact absorption and load recovery performance critical for diabetic protective shoes? Essential Safety Guide

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team

- How does structural resistance of footwear affect physiological stress? Mastering Heat Balance in Protective Gear

- How is the balance between electronic component integration and durability achieved in smart assistive footwear?

- Why is it essential for footwear quality testing labs to have professional safety equipment? Ensure Product Viability