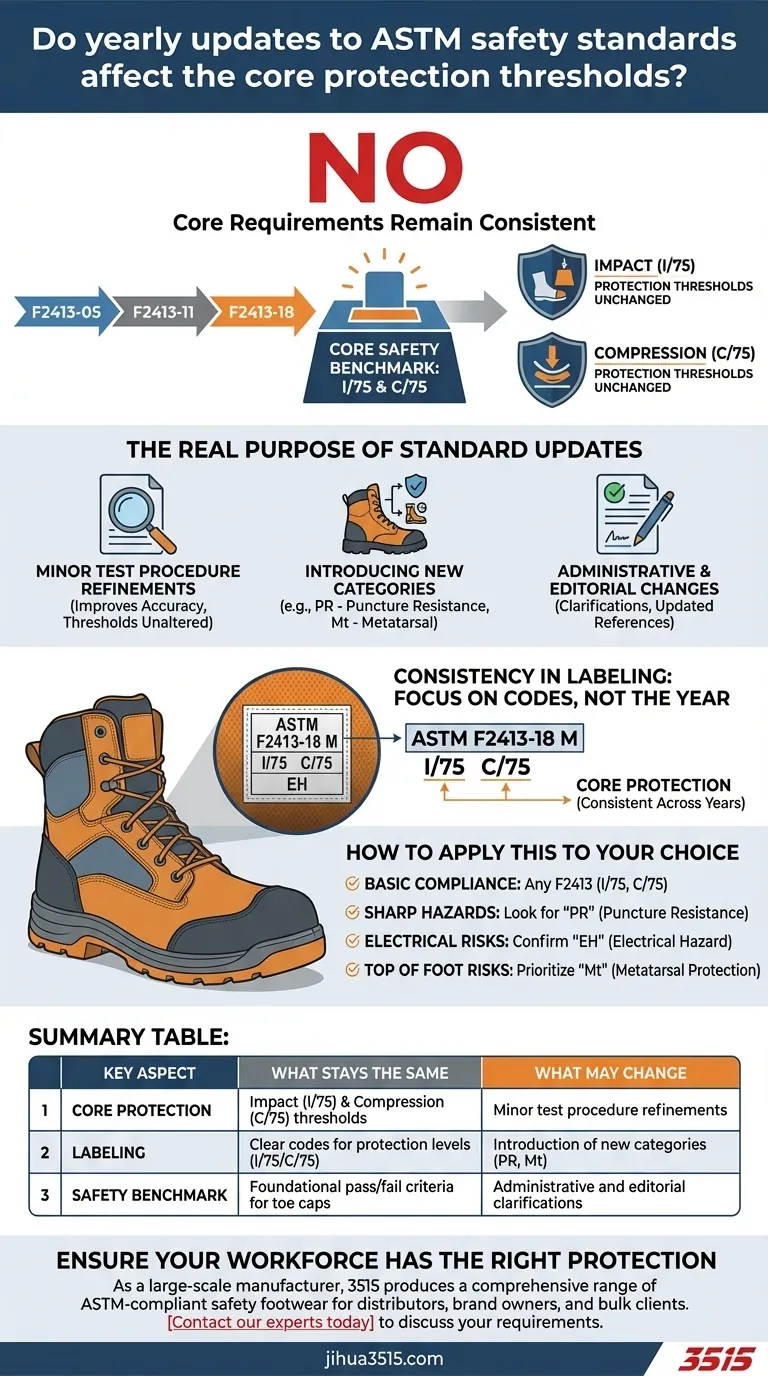

In short, no. Yearly updates to ASTM safety standards for footwear, such as the transition from ASTM F2413-05 to F2413-11 or F2413-18, do not alter the fundamental protection thresholds. The core requirements for impact and compression resistance remain consistent across these versions, ensuring a stable and reliable safety benchmark.

The specific year attached to an ASTM standard (e.g., "-11" or "-18") primarily signifies the date of the last review or revision, not a change in the core safety performance criteria. Understanding the label format is the key to confirming your footwear's protection level, regardless of the standard's year.

Why the Year Doesn't Change the Core Standard

ASTM International (American Society for Testing and Materials) periodically reviews its standards to ensure they remain relevant. However, for established standards like those for protective footwear, the foundational safety tests are mature and well-defined.

The Foundation: Impact and Compression Ratings

The heart of the ASTM F2413 standard is its pass/fail test for the protective toe cap. This test has two main components that have remained consistent for decades.

The Impact (I) rating tests the toe cap's ability to withstand a heavy object dropping on it. The standard rating is I/75, which means it protects against an impact of 75 foot-pounds.

The Compression (C) rating tests the toe cap's ability to resist crushing forces from a slow-moving, heavy object. The standard is C/75, signifying protection against a compressive load of 2,500 pounds.

Consistency in Labeling

The labeling system is designed for clarity and consistency across different standard years. A boot compliant with any recent version of the standard will have a clear, multi-line label.

For example, a label might read: ASTM F2413-18 M/I/75/C/75 EH

This tells you the standard year (2018), the gender (Male), the impact rating (75), the compression rating (75), and any additional protections like Electrical Hazard (EH). The I/75 and C/75 values are the same whether the first line says F2413-05, F2413-11, or F2413-18.

The Real Purpose of Standard Updates

If the core ratings don't change, why are the standards updated? The revisions typically address more nuanced aspects of safety footwear.

Minor Test Procedure Refinements

Updates may slightly alter the methodology of how a test is performed. This is done to improve the repeatability and accuracy of the test results, but it does not change the pass/fail threshold itself.

Introducing New Protection Categories

Revisions are often used to formally incorporate new types of protection. For instance, standards for puncture resistance (PR) or metatarsal protection (Mt) are integrated into the main document, providing a unified framework for all safety features.

Administrative and Editorial Changes

Many updates are simply administrative. They may involve clarifying language, updating references to other standards, or making editorial corrections to ensure the document is as clear as possible for manufacturers and testing labs.

How to Apply This to Your Footwear Choice

Focusing on the label's protection codes is more important than fixating on the year of the standard. This ensures you are matching the boot's capabilities to your workplace hazards.

- If your primary focus is basic safety compliance: Any footwear marked with ASTM F2413, regardless of the year, meets the foundational I/75 and C/75 requirements for toe protection.

- If you work with sharp ground-level hazards: Look for the "PR" designation on the label, which indicates Puncture Resistance, a critical feature not present in all safety boots.

- If you work around live electrical circuits: You must confirm the presence of the "EH" (Electrical Hazard) rating to ensure protection against accidental contact.

- If your workplace has risks of objects falling on the top of your foot: Prioritize footwear with the "Mt" (Metatarsal) rating for protection that extends beyond just the toe cap.

Ultimately, the ASTM F2413 standard provides a reliable and consistent safety benchmark, and its yearly updates refine, rather than redefine, its core protective mission.

Summary Table:

| Key Aspect | What Stays the Same | What May Change |

|---|---|---|

| Core Protection | Impact (I/75) & Compression (C/75) thresholds | Minor test procedure refinements |

| Labeling | Clear codes for protection levels (e.g., I/75/C/75) | Introduction of new categories (e.g., PR, Mt) |

| Safety Benchmark | Foundational pass/fail criteria for toe caps | Administrative and editorial clarifications |

Ensure your workforce has the right protection for the job. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get durable, reliable, and correctly certified footwear. Contact our experts today to discuss your specific safety requirements and procurement needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?