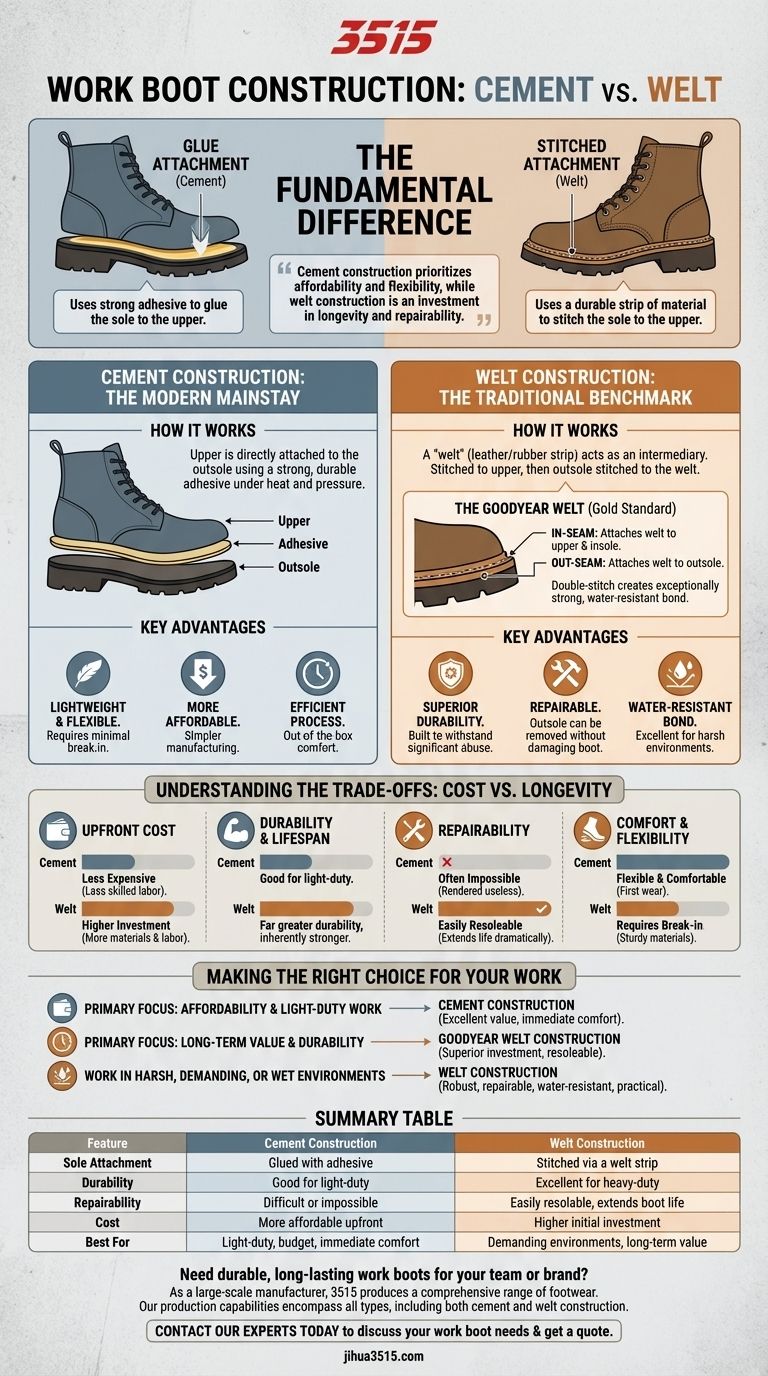

The fundamental difference between cement and welt construction in work boots is how the sole is attached to the upper part of the boot. Cement construction uses a strong adhesive to glue the sole on, while welt construction uses a durable strip of material to stitch the sole to the upper. This single distinction dictates the boot's durability, repairability, and cost.

Cement construction prioritizes affordability and out-of-the-box flexibility at the cost of long-term durability. In contrast, welt construction is an investment in longevity and repairability, creating a much tougher, resoleable boot.

Cement Construction: The Modern Mainstay

Cement construction is a common, modern, and efficient method for assembling footwear, including many types of work boots. The process is straightforward and less labor-intensive than traditional methods.

How It Works

The upper part of the boot is shaped and then attached directly to the outsole using a strong, durable adhesive, much like a high-performance glue. The bond is secured under heat and pressure.

Key Advantages

This method produces boots that are typically lightweight and flexible right out of the box, requiring minimal break-in time. The simpler manufacturing process also makes them significantly more affordable.

Welt Construction: The Traditional Benchmark

Welt construction is a hallmark of high-quality, durable footwear. It involves more steps and materials, creating a boot that is built to last and withstand significant abuse.

How It Works

A "welt"—a strip of leather, rubber, or plastic—acts as an intermediary. First, the welt is stitched to the boot's upper. Then, the outsole is stitched to that same welt.

The Goodyear Welt

The Goodyear welt is considered the gold standard for heavy-duty work boots. It uses two independent stitches: one to attach the welt to the upper and insole (the "in-seam"), and another to attach the welt to the outsole (the "out-seam"). This double-stitch creates an exceptionally strong and water-resistant bond.

Key Advantages

The primary benefits are superior durability and repairability. Because the outsole is stitched to the welt and not directly to the upper, a worn-out sole can be removed and replaced by a cobbler without damaging the rest of the boot.

Understanding the Trade-offs: Cost vs. Longevity

Choosing between these two construction methods involves a clear trade-off between upfront cost and long-term value.

Upfront Cost

Cemented boots are almost always less expensive. The streamlined manufacturing process requires less skilled labor and time, reducing the final price for the consumer.

Durability & Lifespan

Welted boots, particularly those with a Goodyear welt, offer far greater durability. The stitched construction is inherently stronger than a glued bond and is better suited for harsh work environments.

Repairability

This is the most significant difference. When the sole of a cemented boot wears out or separates, it is often impossible to repair effectively, rendering the boot useless. A welted boot, however, can be resoled multiple times, dramatically extending its usable life.

Comfort & Flexibility

Cemented boots generally feel more flexible and comfortable from the first wear. The robust nature of a welted boot often requires a break-in period as the sturdy materials conform to your foot.

Making the Right Choice for Your Work

Your decision should be based entirely on your job's demands, your budget, and how long you expect your boots to last.

- If your primary focus is affordability and light-duty work: Cement construction offers excellent value with immediate comfort for less demanding environments.

- If your primary focus is long-term value and durability: Goodyear welt construction is the superior investment, as the ability to resole the boots can save you money over many years.

- If you work in harsh, demanding, or wet environments: The robust, repairable, and more water-resistant nature of a welted boot makes it the most practical and reliable choice.

Understanding this core construction difference empowers you to invest in a true tool for your feet, not just a temporary piece of footwear.

Summary Table:

| Feature | Cement Construction | Welt Construction |

|---|---|---|

| Sole Attachment | Glued with adhesive | Stitched via a welt strip |

| Durability | Good for light-duty | Excellent for heavy-duty |

| Repairability | Difficult or impossible to resole | Easily resolable, extends boot life |

| Cost | More affordable upfront | Higher initial investment |

| Best For | Light-duty work, budget, immediate comfort | Demanding environments, long-term value |

Need durable, long-lasting work boots for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including both cement and welt construction methods. We can help you select or manufacture the perfect boot to meet your specific demands for durability, cost, and performance.

Contact our experts today to discuss your work boot needs and get a quote.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What additional features do wildland boots have? Unmatched Protection for Extreme Conditions

- When and by whom were engineer boots first produced? Discover the Origins of an Industrial Icon

- What features distinguish work boots from other types of cowboy boots? A Guide to Safety vs. Riding Performance

- What are the disadvantages of lace-up work boots? Weighing Convenience Against Support

- What safety boots are recommended for the transportation industry? Find the Perfect Fit for Your Role

- How can you ensure consistent comfort in work boots? Focus on Fit, Materials & Ergonomics

- Why are industrial safety boots with steel toes necessary for machine operators? Essential Foot Protection for Safety

- What comfort features are found in PVC work boots? Achieve All-Day Comfort in Wet Conditions