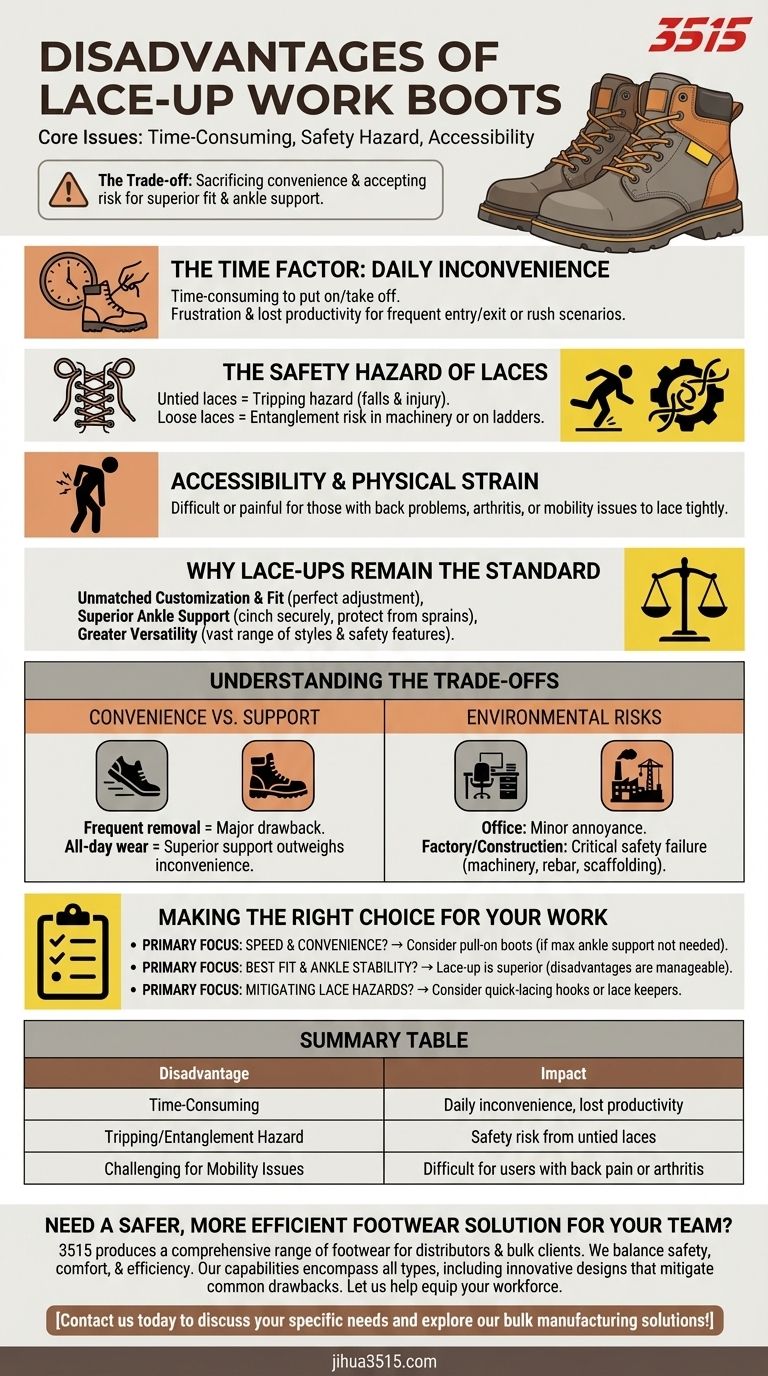

Ultimately, the disadvantages of lace-up work boots boil down to three core issues: they are time-consuming to put on and take off, their laces can present a significant tripping or entanglement hazard if they come undone, and they can be challenging for individuals with mobility limitations to manage.

The decision to choose a lace-up work boot is a fundamental trade-off. You are sacrificing a degree of convenience and accepting a specific safety risk in exchange for a superior, highly customizable fit and enhanced ankle support.

Deconstructing the Disadvantages

While they may seem minor, the drawbacks of lace-up boots can have a real impact on your daily work life, especially concerning efficiency and safety.

The Time Factor: A Daily Inconvenience

Putting on and taking off lace-up boots properly takes time. For workers who need to enter and exit clean environments frequently or are simply in a rush, this daily ritual can become a point of frustration and lost productivity.

The Safety Hazard of Laces

Untied laces are a well-known safety risk. They create a direct tripping hazard that can lead to falls and serious injury on a busy job site.

Furthermore, loose laces can get caught in moving machinery or on ladders, posing a severe entanglement risk in certain industrial or construction environments.

Accessibility and Physical Strain

For individuals with back problems, arthritis, or other mobility issues, the act of bending over and tightly lacing boots can be difficult or painful. This makes lace-up boots a less accessible option for a segment of the workforce.

Why Lace-Ups Remain the Standard

To understand if these disadvantages are deal-breakers, it's critical to weigh them against the significant benefits that make lace-up boots the industry standard. These drawbacks exist as a trade-off for distinct advantages.

Unmatched Customization and Fit

The primary advantage of a lace-up boot is the ability to achieve a perfectly customized fit. You can adjust the tightness across different parts of your foot to accommodate its unique shape, ensuring all-day comfort and reducing slippage.

Superior Ankle Support

The lacing system allows you to cinch the boot securely around your ankle. This provides robust support that helps protect against sprains and twists, which is critical when navigating uneven terrain or carrying heavy loads. Pull-on boots rarely offer this level of targeted ankle stability.

Greater Versatility in Design

The market for lace-up work boots is vast. They are available in a wider range of styles, materials, and specialized safety features, from steel toes and electrical hazard protection to moisture-wicking linings, making it easier to find a boot that meets exact job requirements.

Understanding the Trade-offs

The choice is not about which boot is "better" in a vacuum, but which is better for your specific context. The significance of each disadvantage is determined entirely by your work environment and personal needs.

Convenience vs. Support

If your job requires you to frequently remove your boots, the time-consuming nature of laces is a major drawback. However, if you wear your boots for an entire shift on rugged ground, the superior support they offer will almost always outweigh the initial inconvenience.

Environmental Risks

An untied shoelace is a minor annoyance in an office setting. On a factory floor with rotating equipment or a construction site with rebar and scaffolding, that same untied lace becomes a critical safety failure. You must assess your environment's risk level honestly.

Making the Right Choice for Your Work

Evaluate your daily tasks and priorities to determine if the trade-offs associated with lace-up boots are acceptable.

- If your primary focus is speed and convenience: A pull-on boot may be a more practical choice, provided you don't require maximum ankle support.

- If your primary focus is the best possible fit and ankle stability: The lace-up boot is the superior option, and its disadvantages are manageable parts of ownership.

- If your primary focus is mitigating lace-related hazards: Consider modern lace-up boots with quick-lacing hooks or using aftermarket lace keepers to ensure they stay tied and secure throughout the day.

Ultimately, choosing the right boot means understanding that every design feature comes with an inherent compromise.

Summary Table:

| Disadvantage | Impact |

|---|---|

| Time-Consuming to Put On/Take Off | Daily inconvenience, lost productivity |

| Tripping/Entanglement Hazard | Safety risk from untied laces |

| Challenging for Mobility Issues | Difficult for users with back pain or arthritis |

Need a Safer, More Efficient Footwear Solution for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We understand the critical balance between safety, comfort, and efficiency in work boots. Our production capabilities encompass all types of shoes and boots, including innovative designs that mitigate common drawbacks.

Let us help you equip your workforce with the right footwear. Contact us today to discuss your specific needs and explore our bulk manufacturing solutions!

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are the key benefits of wearing motorcycle boots? Essential Safety & Comfort for Riders

- What factors do people commonly consider when choosing work boots? A Guide to Safety, Comfort & Fit

- Why should you avoid using products with lanolin on leather boots? Preserve Boot Structure and Durability

- How can leather work boots be protected from environmental elements? A 3-Step Guide to Lasting Durability

- What are the different types of PVC boots available? Choose the Right Boot for Your Job

- What are the advantages of full leather boots? Unmatched Durability & Long-Term Value

- What additional protection do metatarsal boots provide? Achieve Full Instep Safety from Impact and Compression

- Why are waterproof and breathable properties important in farming and gardening boots? The Key to All-Day Comfort and Foot Health