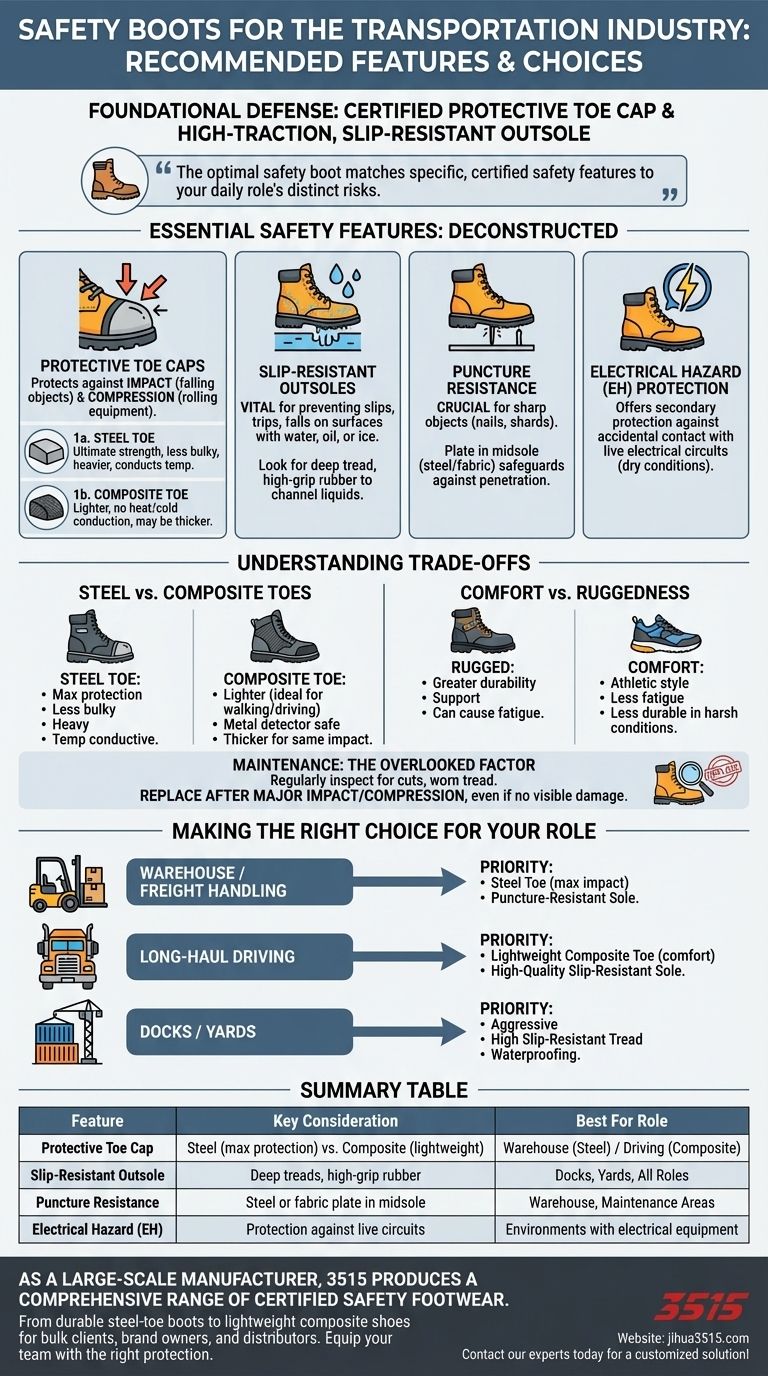

For the transportation industry, the best safety boots combine two non-negotiable features: a certified protective toe cap and a high-traction, slip-resistant outsole. These elements provide the foundational defense against the most common hazards in this field, from falling freight in a warehouse to slippery surfaces at a loading dock.

The optimal safety boot is not a one-size-fits-all solution. It's about methodically matching specific, certified safety features to the distinct risks of your daily role, whether you're behind the wheel, on the dock, or in the yard.

Deconstructing the Essential Safety Features

Understanding the core components of a safety boot allows you to make an informed decision based on the protection you actually need, not just a brand name.

The Foundation: Protective Toe Caps

The most recognized feature of a safety boot is its reinforced toe. This component is designed to protect your feet from both impact (falling objects) and compression (rolling equipment).

The traditional choice has always been the steel toe, known for its ultimate strength. However, composite toes (made from materials like carbon fiber, Kevlar, or plastic) are a modern alternative that is lighter and does not conduct heat or cold.

The Critical Grip: Slip-Resistant Outsoles

Slips, trips, and falls are among the most frequent causes of injury. A slip-resistant outsole is absolutely vital in transportation, where surfaces can be contaminated with water, oil, or ice.

Look for boots with deep tread patterns and outsoles made from high-grip rubber compounds. This design works to channel liquids away from the sole, maximizing contact with the ground and ensuring stable footing.

Beyond the Basics: Puncture Resistance

Warehouse floors, shipping yards, and maintenance areas are often littered with sharp objects like nails, screws, and metal shards. A puncture-resistant plate is a crucial feature for anyone working in these environments.

These protective midsoles can be made of steel or flexible woven fabrics, safeguarding the bottom of your foot from penetration hazards.

Electrical Hazard (EH) Protection

Many work environments in the transportation sector involve proximity to live electrical circuits or powered equipment.

Boots with an Electrical Hazard (EH) rating have soles and heels designed to offer a secondary source of protection against accidental contact with live electrical circuits under dry conditions.

Understanding the Trade-offs

Choosing the perfect boot often involves balancing competing factors. Being aware of these trade-offs is key to selecting footwear that is both safe and practical for all-day wear.

Steel vs. Composite Toes

A steel toe offers maximum protection and is often less bulky than a composite version. However, it is heavier and can become uncomfortably cold or hot in extreme temperatures.

A composite toe is significantly lighter, making it ideal for drivers or those who walk long distances. It also won't set off metal detectors, but may need to be slightly thicker to provide the same level of impact resistance as steel.

Comfort vs. Ruggedness

Heavier, more robustly constructed boots typically offer greater durability and support. The downside is that they can lead to fatigue over a long shift, especially for tasks that require a lot of walking or climbing.

Lighter, more athletic-style safety shoes provide excellent comfort but may not withstand the harsh abuse of a freight yard for as long as their heavier counterparts.

The Overlooked Factor: Maintenance

Even the best boots require care. Regularly inspect your footwear for deep cuts, separated soles, or worn-down tread that reduces slip resistance.

Critically, any boot that has sustained a significant impact or compression event must be replaced. The internal protective structure is designed to absorb a single major blow and is compromised afterward, even if no visible damage is apparent.

Making the Right Choice for Your Role

Select your footwear based on the primary hazards you face every day.

- If your primary focus is warehouse operations or freight handling: Prioritize a steel toe for maximum impact protection and a puncture-resistant sole.

- If your primary focus is long-haul driving: Choose a lightweight composite toe boot for all-day comfort, ensuring it has a high-quality slip-resistant sole for deliveries.

- If your primary focus is working on docks or in yards: Your priority should be a boot with an aggressive, highly slip-resistant tread and consider waterproofing.

Ultimately, investing in the right safety footwear is a direct investment in your own well-being on the job.

Summary Table:

| Feature | Key Consideration | Best For Role |

|---|---|---|

| Protective Toe Cap | Steel (max protection) vs. Composite (lightweight) | Warehouse (Steel) / Driving (Composite) |

| Slip-Resistant Outsole | Deep treads, high-grip rubber | Docks, Yards, All Roles |

| Puncture Resistance | Steel or fabric plate in midsole | Warehouse, Maintenance Areas |

| Electrical Hazard (EH) | Protection against live circuits | Environments with electrical equipment |

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether you need durable steel-toe boots for warehouse crews or lightweight composite-toe shoes for drivers, our production capabilities cover all types of occupational footwear. Let us help you equip your team with the right protection. Contact our experts today for a customized solution!

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- How do Western-style work boots protect the feet? A Complete Guide to Industrial Foot Safety

- What does the 'MT' in ASTM F2413-18 stand for? Essential Metatarsal Protection Explained

- What types of hazards do firefighter boots protect against? Essential Multi-Hazard Footwear for Firefighters

- How do knee-high or ankle boots reduce injury risk? Essential Protection for High-Risk Work

- How can you achieve a Classic Workwear Vibe with moc toe boots? Build a Rugged, Authentic Style

- What is the difference between a cowboy boot and a work boot? Choosing the Right Footwear for Your Task

- What industries require oil-resistant work boots? Protect Your Workforce in Hazardous Environments

- What are some ASTM standards for work boots? A Guide to Certified Footwear Safety