The primary benefit of insulated work boots is their ability to provide critical warmth and comfort, protecting your feet from cold exposure in harsh weather conditions. This thermal regulation is essential for maintaining safety, focus, and the ability to work effectively outdoors or in unheated environments.

In demanding conditions, your gear is a critical safety system. Insulated boots are not just about comfort; they are an engineered solution designed to protect you from the dangers of cold, moisture, and related job-site hazards, ensuring your feet are not a point of failure.

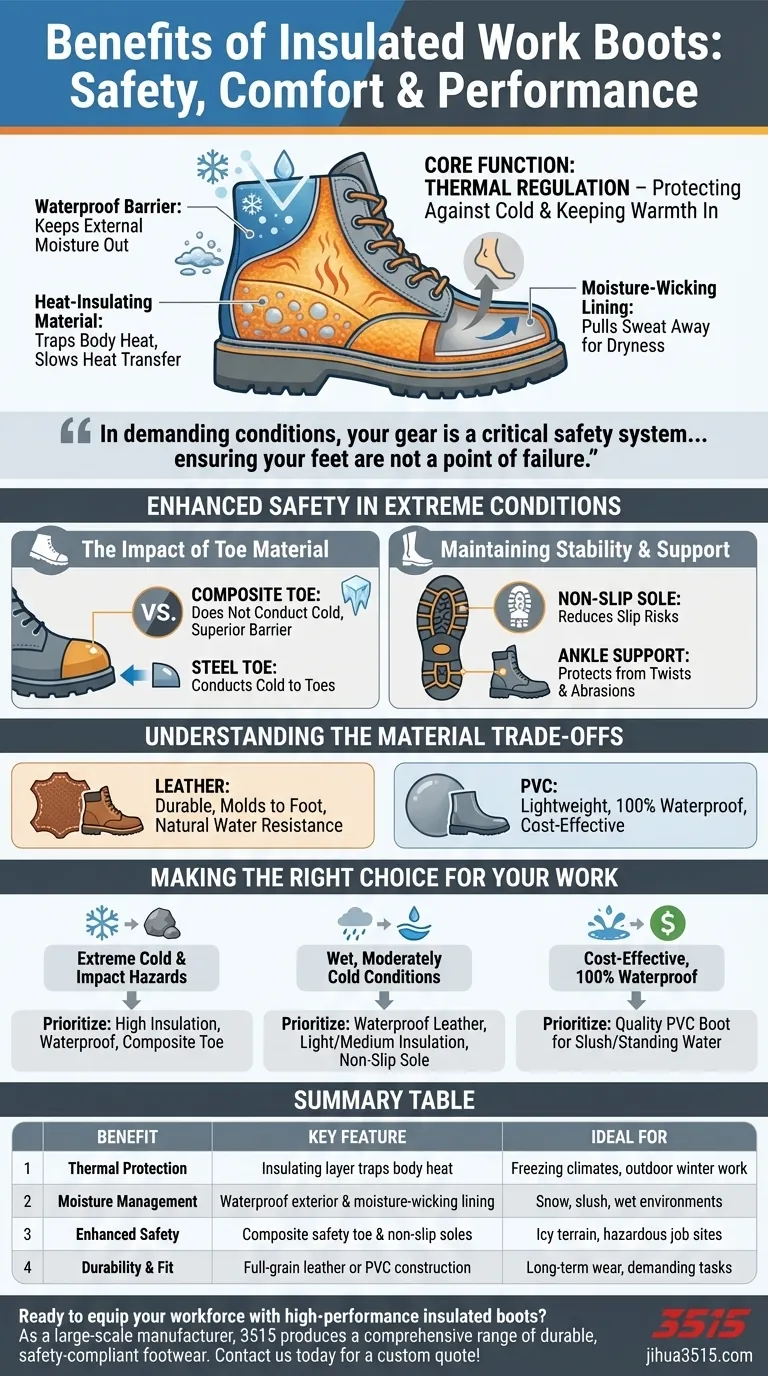

The Core Function: Thermal Regulation

Properly managing the temperature of your feet is fundamental to your overall well-being and performance on a job site. Insulated boots are specifically designed to create a stable internal environment.

Protecting Against the Cold

The defining feature is a dedicated layer of heat-insulating material. This layer traps air, creating a thermal barrier that significantly slows the transfer of heat from your feet to the cold exterior.

This makes work in snowy or freezing climates not just more bearable, but safer by reducing the risk of cold-related injuries like frostbite.

Keeping Moisture Out, and Warmth In

Insulation's effectiveness plummets if your feet get wet. For this reason, many insulated boots are also waterproof.

By preventing external moisture from snow or slush from penetrating the boot, they keep the insulating material and your socks dry. This combination is critical for retaining heat.

The Role of Internal Moisture Management

High-quality boots also feature moisture-wicking linings. These materials pull sweat away from your skin, keeping your feet dry from the inside. Dry feet are warm feet.

Enhanced Safety in Extreme Conditions

In harsh environments, the benefits of insulated boots extend beyond simple warmth to encompass features that are critical for overall safety.

The Impact of Toe Material

For work requiring a safety toe, the material choice is crucial in extreme temperatures. A composite toe is highly recommended over a steel toe.

Steel is an efficient conductor of energy, meaning it will transfer cold directly to your toes. Composite materials do not conduct cold, providing a far superior and safer barrier in freezing conditions.

Maintaining Stability and Support

Working in cold weather often means dealing with ice, snow, and uneven terrain. Insulated boots are typically built on robust, non-slip soles to reduce the danger of slips and falls.

They also often feature a high-cut design to provide essential ankle support, protecting you from twists and abrasions.

Understanding the Material Trade-offs

The material of your boot directly impacts its performance, durability, and suitability for specific tasks. Choosing the right one is key.

Leather: Durable and Conforming

Full-grain leather is a classic choice, known for its exceptional durability and natural water resistance. High-quality leather boots can be treated to be fully waterproof.

A significant benefit of leather is that it breaks in and molds to the shape of your foot over time, providing a custom, comfortable fit.

PVC: Lightweight and Waterproof

For environments where being 100% waterproof is the top priority, PVC (Polyvinyl Chloride) boots are an excellent option.

These boots are typically less expensive and lighter than leather, and they offer good protection against certain chemicals. However, their insulation levels and durability can vary.

Making the Right Choice for Your Work

Selecting the correct boot requires matching its features to the specific demands of your environment and tasks.

- If your primary focus is extreme cold and potential impact hazards: Prioritize a boot with high levels of insulation, a fully waterproof design, and a composite safety toe.

- If your primary focus is wet, moderately cold conditions: A waterproof leather boot with light-to-medium insulation and a reliable non-slip sole is your most versatile choice.

- If your primary focus is cost-effective, 100% waterproof protection: A quality PVC boot is an ideal solution for keeping your feet dry in slush and standing water.

Choosing the right insulated boot is a direct investment in your safety and ability to perform at your best, no matter the conditions.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Thermal Protection | Insulating layer traps body heat | Freezing climates, outdoor winter work |

| Moisture Management | Waterproof exterior & moisture-wicking lining | Snow, slush, wet environments |

| Enhanced Safety | Composite safety toe & non-slip soles | Icy terrain, hazardous job sites |

| Durability & Fit | Full-grain leather or PVC construction | Long-term wear, demanding tasks |

Ready to equip your workforce with high-performance insulated boots? As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-compliant footwear for distributors, brand owners, and bulk clients. We can deliver the exact boots your team needs to work safely and productively in any condition. Contact us today for a custom quote and discover the 3515 advantage!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How do versatile work shoes maintain a balance between protection and comfort? Unlock Efficiency in Mixed Environments

- Why is waterproofing important in construction boots? Protect Your Feet and Your Investment

- Why are customized 3D printed measurement boots utilized in a sled friction meter? Elevate Testing Accuracy

- What features should cowboy boots have for rugged, physical labor jobs? Essential Safety & Durability Guide

- What are some tips for wearing engineer boots? Master the Pants-to-Boot Silhouette

- What insulation rating is recommended for extremely cold conditions? Find Your Perfect Fit

- What are the key roles of work boots in labor-intensive jobs? Essential for Safety, Performance & Comfort

- What role does the midsole play in work boots? A Guide to Comfort & Durability