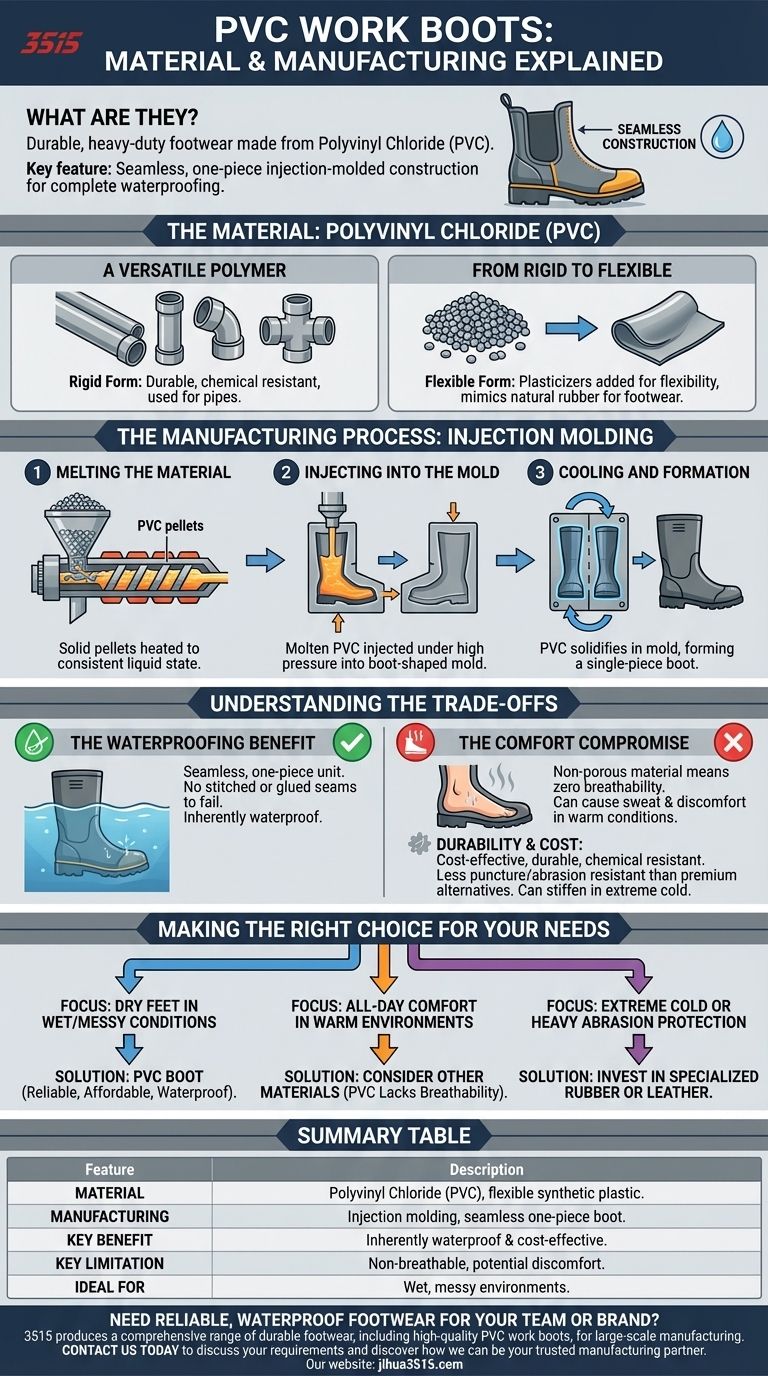

To put it simply, PVC work boots are durable, heavy-duty footwear made from Polyvinyl Chloride, a synthetic plastic polymer. They are manufactured using a process called injection molding, where molten PVC is injected into a boot-shaped mold to create a seamless, completely waterproof final product.

The single-piece construction from injection molding is the defining feature of PVC boots, making them an inherently waterproof and cost-effective choice for wet or messy work environments.

The Material: What is Polyvinyl Chloride?

Polyvinyl Chloride, or PVC, is one of the most widely produced synthetic plastics in the world. Its properties can be modified for a vast range of applications.

A Versatile Polymer

In its rigid form, PVC is famously used for pipes and plumbing fixtures. It's known for its durability and resistance to chemicals and corrosion.

From Rigid to Flexible

Through the addition of plasticizers during processing, rigid PVC can be transformed into a flexible material. This flexible form mimics the properties of natural rubber, making it an ideal compound for footwear.

The Manufacturing Process: Injection Molding

The method used to create PVC boots is remarkably efficient and is key to their most important features. The entire boot is formed in a single, automated process.

Step 1: Melting the Material

The process begins with small, solid PVC pellets. These pellets are heated until they melt into a consistent, liquid state.

Step 2: Injecting into the Mold

This molten PVC is then injected under high pressure into a detailed, two-part mold shaped like a boot. The pressure ensures the liquid plastic fills every part of the mold completely.

Step 3: Cooling and Formation

The mold is then allowed to cool. As the PVC cools, it solidifies and hardens, taking on the exact shape of the mold to form a finished, one-piece boot.

Understanding the Trade-offs

The material and manufacturing process give PVC boots distinct advantages, but they also come with inherent limitations you must consider.

The Waterproofing Benefit

Because the boot is created as a single, seamless unit, there are no stitched or glued seams that can fail or leak. This makes injection-molded PVC boots fundamentally waterproof.

The Comfort Compromise

This same non-porous, waterproof quality means the material has zero breathability. In warm conditions or during strenuous work, this can lead to sweat and discomfort for the wearer.

Durability and Cost

Injection molding is a highly efficient and cost-effective manufacturing process. While PVC is durable and resistant to many chemicals, it may not offer the same level of puncture or abrasion resistance as premium rubber or leather alternatives. It can also become stiff in extreme cold.

Making the Right Choice for Your Needs

Understanding how PVC boots are made helps you decide if they are the correct tool for your job.

- If your primary focus is keeping your feet dry in wet or messy conditions: The seamless, waterproof nature of a PVC boot is one of the most reliable and affordable solutions available.

- If your primary focus is all-day comfort in a warm environment: The lack of breathability may be a significant downside, and you might consider other materials.

- If your primary focus is protection from extreme cold or heavy abrasion: You may want to invest in boots made from specialized rubber or leather compounds designed for those specific hazards.

Ultimately, choosing the right work boot means matching the material's core properties to the demands of your environment.

Summary Table:

| Feature | Description |

|---|---|

| Material | Polyvinyl Chloride (PVC), a flexible, durable synthetic plastic. |

| Manufacturing | Injection molding, creating a seamless, one-piece boot. |

| Key Benefit | Inherently waterproof and cost-effective. |

| Key Limitation | Non-breathable, which can cause discomfort in warm conditions. |

| Ideal For | Wet, messy environments where keeping feet dry is the top priority. |

Need reliable, waterproof footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear, including high-quality PVC work boots, for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the right protective footwear tailored to your specific needs.

Contact us today to discuss your requirements and discover how we can be your trusted manufacturing partner.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

People Also Ask

- What features should be considered when choosing work boots for dual use? Find the Perfect Balance for Work & Casual Wear

- What are the different toe styles for cowboy boots? Find Your Perfect Fit for Work or Fashion

- What should delivery drivers look for in work shoes? Essential Features for Safety & Comfort

- What are the differences between fire boots and regular work boots? A Guide to Life-Saving Footwear

- What are the key considerations when choosing work boots? Prioritize Safety, Durability, and Comfort

- What are Yard boots designed for? Specialized Footwear for Stable & Farm Work

- What are the key features of logger boots? A Guide to Unmatched Stability & Safety

- Can work boots be cleaned in a washing machine? Avoid Damage and Extend Boot Life