At their core, overboots and shoe covers are disposable, protective sleeves worn directly over your primary footwear. They serve as a critical barrier, isolating your regular boots from specific environmental hazards and preventing cross-contamination between a hazardous area and a clean one.

The primary function of an overboot or shoe cover is not to replace your main protective footwear, but to add a specialized, often temporary, layer of protection against contaminants, liquids, and particulates that would otherwise ruin your boots or be tracked to other areas.

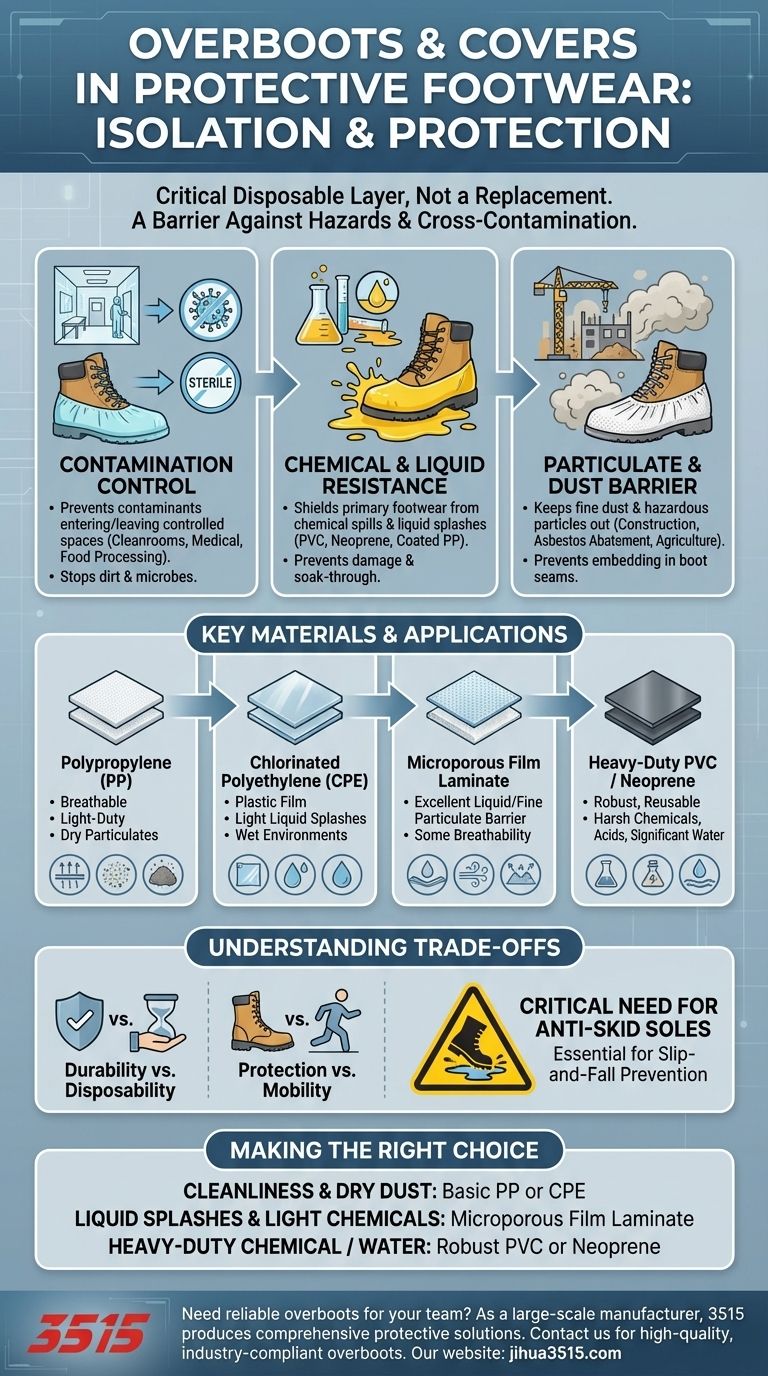

The Core Purpose: Isolation and Protection

Understanding when to use an overboot comes down to two key principles: protecting the environment from your footwear, and protecting your footwear (and you) from the environment.

Contamination Control

In many sensitive settings, the goal is to prevent contaminants from entering or leaving a controlled space.

Shoe covers are essential in cleanrooms, medical facilities, and food processing plants. They stop dirt, dust, and microorganisms on the soles of your shoes from contaminating a sterile environment.

Conversely, they also prevent hazardous materials, like biological agents in a lab or potent dust in a pharmaceutical plant, from being tracked out on your footwear.

Chemical and Liquid Resistance

Standard leather or fabric work boots can be damaged or permanently contaminated by chemical spills and liquid splashes.

Overboots made from materials like PVC, neoprene, or coated polypropylene provide a waterproof and chemical-resistant barrier. This protects expensive primary footwear from damage and prevents hazardous liquids from soaking through to the wearer's skin.

Particulate and Dust Barrier

In environments like construction sites, asbestos abatement zones, or agricultural settings, fine dust and hazardous particulates are a major concern.

A simple shoe cover creates a physical barrier that keeps these particles from embedding in the laces, seams, and materials of your work boots, which can be nearly impossible to decontaminate fully.

Key Materials and Their Applications

The level of protection is determined entirely by the material the cover is made from. Choosing the wrong one can provide a false sense of security.

Polypropylene (PP)

This is a common, low-cost material used for basic, light-duty covers. It is breathable and effective against general dirt and dry particulates but offers minimal resistance to liquids.

Chlorinated Polyethylene (CPE)

Often seen in the classic blue, textured "booties," CPE is a plastic film that provides good protection against light liquid splashes and non-hazardous fluids. It is a step up from polypropylene for wet environments.

Microporous Film Laminate

This advanced material bonds a protective film to a polypropylene base. It offers excellent protection against liquids and fine particulates while still allowing for some breathability, making it more comfortable for extended wear.

Heavy-Duty PVC or Neoprene

These materials are used for true overboots, not just covers. They provide robust, reusable protection against harsh chemicals, acids, and significant water exposure. They are common in hazardous material cleanup and heavy industrial applications.

Understanding the Trade-offs

While highly effective, overboots and shoe covers come with specific considerations that are critical for safety and operational planning.

Durability vs. Disposability

The vast majority of shoe covers are designed for single or limited use. This disposability is a key feature for preventing cross-contamination, but it also represents a recurring operational cost and generates waste.

Protection vs. Mobility

Thicker, more protective overboots made from materials like PVC can be cumbersome. They may reduce a worker's agility and tactile feel with the ground, which can be a safety consideration in itself.

The Critical Need for Anti-Skid Soles

A smooth plastic cover on a wet or smooth floor is a significant slip-and-fall hazard. It is essential to select covers that feature a textured or specially treated anti-skid sole appropriate for the working surface.

Making the Right Choice for Your Task

Selecting the correct overboot or cover is a matter of matching the material and design to the specific hazard you face.

- If your primary focus is cleanliness and dry particulate control: A basic polypropylene (PP) or chlorinated polyethylene (CPE) cover is often sufficient and cost-effective.

- If your primary focus is protection from liquid splashes or light chemicals: A cover made from microporous film laminate provides a reliable barrier without sacrificing all breathability.

- If your primary focus is heavy-duty chemical or water immersion: You need a true overboot made from a robust material like PVC or neoprene for dependable protection.

Ultimately, using the right overboot ensures your primary safety footwear can do its job while being shielded from contamination and damage.

Summary Table:

| Purpose | Material | Best For |

|---|---|---|

| Contamination Control | Polypropylene (PP) | Cleanrooms, Medical Facilities |

| Liquid & Chemical Resistance | PVC, Neoprene | Chemical Spills, Hazardous Material Cleanup |

| Particulate & Dust Barrier | Microporous Film Laminate | Construction, Pharmaceutical Dust Control |

Need reliable overboots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of protective footwear, including durable overboots and covers for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality, industry-compliant solutions tailored to your specific hazards. Protect your workforce and equipment — contact us today for a customized quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the pros and cons of composite safety toes? Weighing Weight vs. Ultimate Protection

- What key features enhance the functionality of firefighter boots? Built for Extreme Safety & Performance

- How do professional protective shoes help reduce lumbar load? Lower Spinal Stress with Superior Foot Stability

- What is the current safety footwear standard in Europe? Your Guide to EN ISO 20345

- What materials are used for fasteners and laces in safety boots? | A Guide to Durability & Safety

- Who should workers consult to determine the right safety footwear for their workplace? Start with Your Employer for a Compliant and Safe Choice

- What is the importance of understanding OSHA safety shoe standards? Ensure Compliance and Protect Your Workforce

- How many people in the US are kept from work annually due to foot injuries? Prevent 60,000+ Lost Workdays