Your first point of contact for determining the correct safety footwear is always your employer, direct supervisor, or safety manager. They are responsible for conducting a formal hazard assessment of the workplace and defining the specific Personal Protective Equipment (PPE) required to keep you safe. This isn't just a suggestion; it's a fundamental part of a workplace safety program.

While your employer dictates the minimum safety requirements based on a formal risk assessment, your understanding of your specific daily tasks is crucial for selecting footwear that is not only compliant but also effective and comfortable.

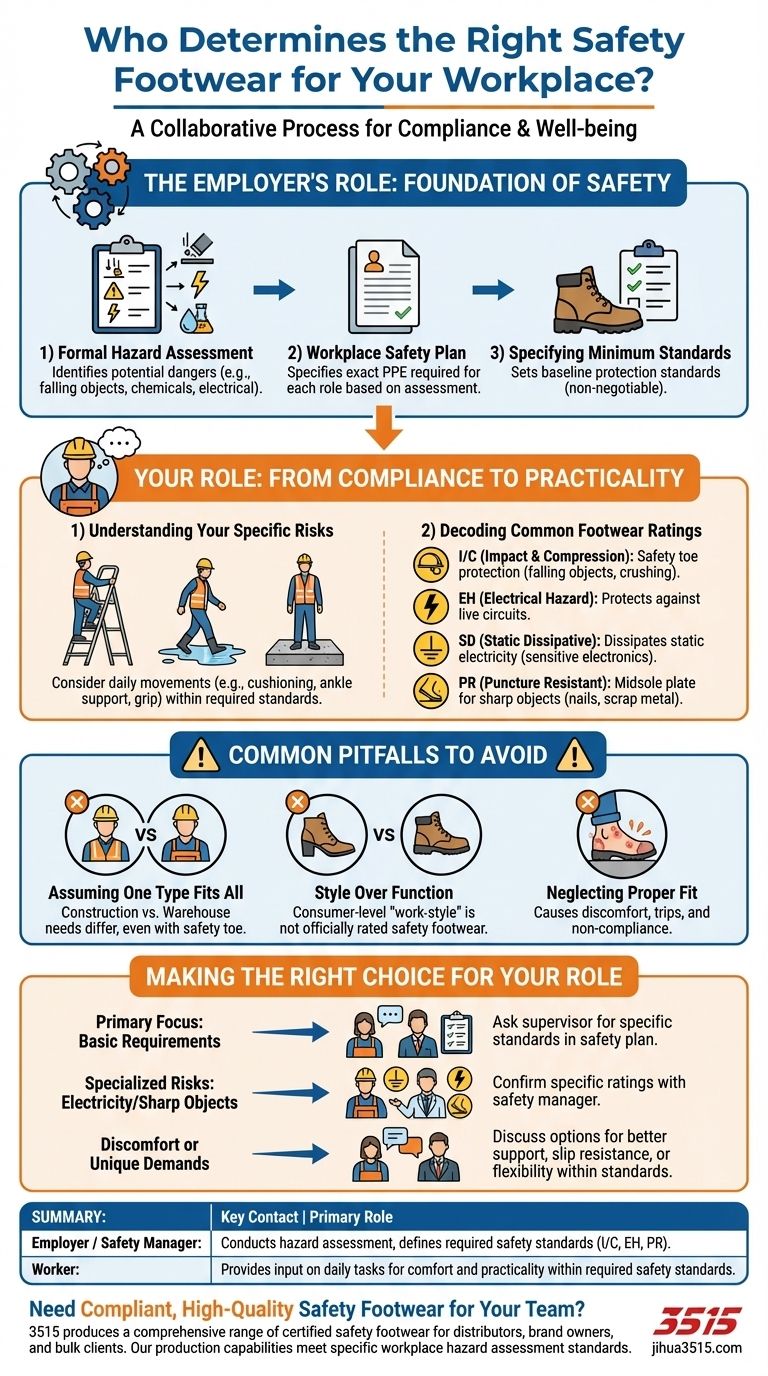

The Employer's Role: The Foundation of Safety

Your organization doesn't choose safety standards arbitrarily. The requirements for your footwear are based on a systematic process designed to identify and mitigate risks.

The Formal Hazard Assessment

Every workplace is required to perform a hazard assessment to identify potential dangers. For feet, this includes risks like falling objects, sharp materials on the ground, electrical currents, or chemical spills.

The Workplace Safety Plan

The results of this assessment are documented in a formal safety plan. This plan specifies the exact type of PPE needed for each role or work area, including the required standards for your footwear.

Specifying Minimum Standards

Based on the safety plan, your employer will provide the minimum required specifications. This is your baseline for protection and the non-negotiable standard you must meet.

Your Role: From Compliance to Practicality

Your employer sets the standard, but your active participation ensures you get footwear that works for you. You have a unique understanding of your day-to-day physical tasks.

Understanding Your Specific Risks

Consider your daily movements. Are you standing on concrete for hours, climbing ladders, or walking on slippery surfaces? These factors influence needs like cushioning, ankle support, and sole grip, which may be options within the required safety standard.

Decoding Common Footwear Ratings

Knowing what the labels mean empowers you to have a more informed conversation with your employer.

- Impact & Compression (I/C): This is the classic safety toe requirement, protecting you from falling objects and crushing forces.

- Electrical Hazard (EH): EH-rated boots protect you from accidental contact with live electrical circuits.

- Static Dissipative (SD): SD-rated footwear is crucial in environments with sensitive electronics, as it safely dissipates static electricity from your body to the ground.

- Puncture Resistant (PR): A plate in the midsole protects you from stepping on sharp objects like nails or scrap metal.

Common Pitfalls to Avoid

Choosing the wrong footwear, even if it meets a basic safety-toe requirement, can introduce new risks or lead to non-compliance.

Assuming One Type Fits All

A boot designed for a construction site may be too heavy or rigid for a warehouse worker who needs to be quick on their feet, even if both require a safety toe.

Prioritizing Style Over Function

Consumer-level "work-style" boots are not a substitute for officially rated safety footwear. Compliance and protection must always be the primary criteria.

Neglecting Proper Fit

Footwear that is too loose or too tight can cause blisters, trips, and long-term fatigue. An uncomfortable boot is more likely to be worn improperly or not at all, defeating its purpose entirely.

Making the Right Choice for Your Role

Use this framework to ensure you are both safe and comfortable.

- If your primary focus is meeting the basic requirement: Ask your supervisor for the specific safety standards listed in your site's hazard assessment and safety plan.

- If your work involves specialized risks like electricity or sharp objects: Confirm with your safety manager that your footwear carries the specific EH or PR rating required for your tasks.

- If you experience discomfort or have unique job demands: Start a conversation with your employer about options that meet the safety standard while also providing better support, slip resistance, or flexibility for your specific needs.

Ultimately, the right safety footwear is a collaborative choice that ensures both regulatory compliance and your personal well-being on the job.

Summary Table:

| Key Contact | Primary Role in Footwear Selection |

|---|---|

| Employer / Safety Manager | Conducts hazard assessment and defines the required safety standards (e.g., I/C, EH, PR). |

| Worker | Provides input on daily tasks for comfort and practicality within the required safety standards. |

Need Compliant, High-Quality Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the specific standards identified in your workplace hazard assessment.

We ensure your workforce is protected, comfortable, and compliant. Contact us today to discuss your requirements and request a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What are the specific functional requirements for safety shoes used in high-load clinical environments? Top 8 Features

- What are the common lower limb injuries among motorcyclists? Protect Yourself from Severe Fractures

- What industries commonly require protective footwear? Essential Foot Safety for High-Risk Sectors

- Why is industrial-grade PPE the most critical safety factor? Secure Your Site with the Final Line of Defense

- What is the ASTM standard for metatarsal protection? Ensuring Your Footwear Meets the 75 ft-lb Impact Test

- What benefits do safety shoes provide in harsh weather conditions? Ensure Worker Safety and Productivity

- What are the protective functions of industrial-grade safety shoes in hotel housekeeping? Enhancing Safety & Traction

- What are the OSHA recommendations for wearing protective footwear? A Legal Guide to Workplace Foot Safety