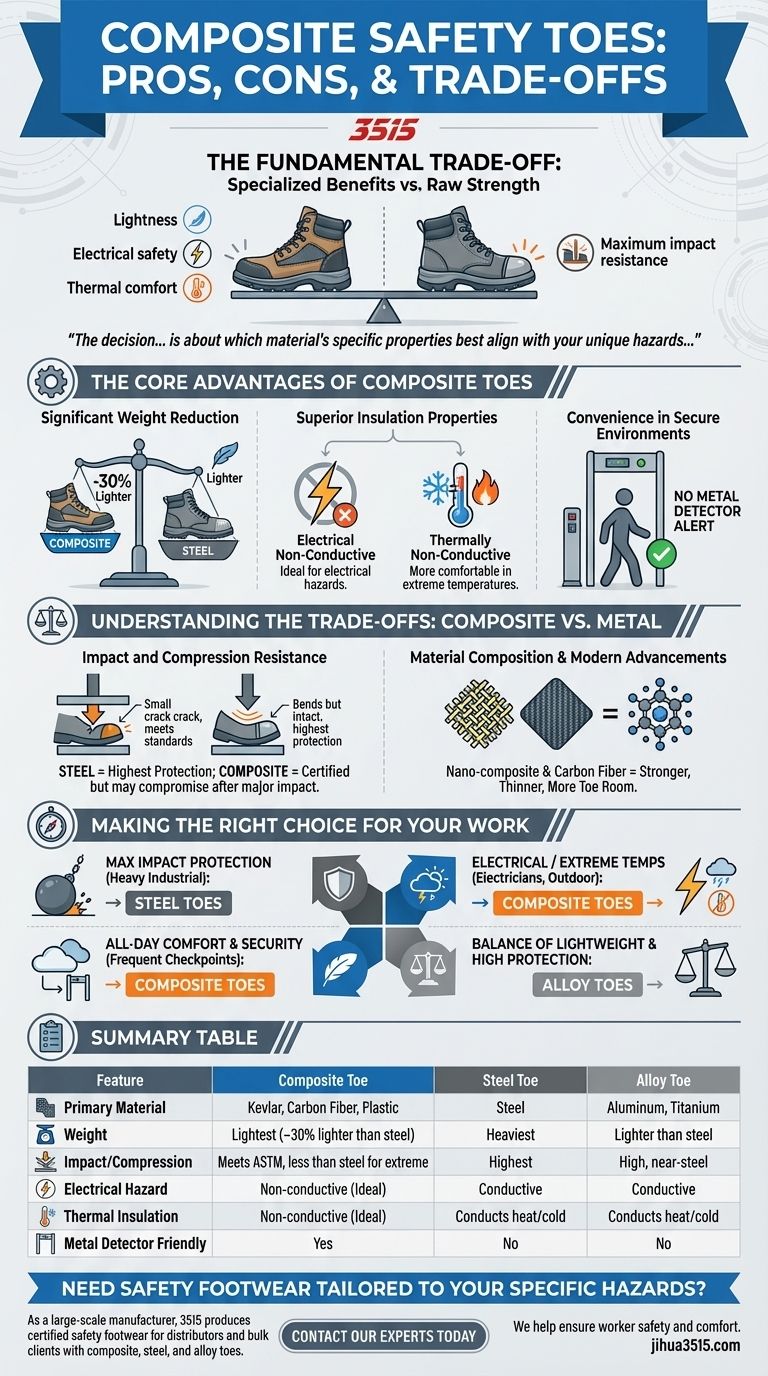

The fundamental trade-off is one of specialized benefits versus raw strength. Composite safety toes offer significant advantages in weight, electrical resistance, and thermal insulation. However, they typically provide less resistance to extreme impact and compression forces when compared to their traditional steel counterparts.

The decision between composite and other safety toes is not about which is universally "better," but which material's specific properties best align with the unique hazards and daily demands of your specific work environment.

The Core Advantages of Composite Toes

Composite safety toes are engineered from non-metallic materials like Kevlar, carbon fiber, fiberglass, and plastic. This construction gives them a distinct set of advantages over traditional metal caps.

Significant Weight Reduction

Composite caps are approximately 30% lighter than steel toe caps. This reduction in weight can lead to a noticeable decrease in foot fatigue over a long workday, enhancing overall comfort.

Superior Insulation Properties

Because they are non-metallic, composite materials are poor conductors of energy. This creates two critical safety and comfort benefits.

First, they are electrically non-conductive, making them the ideal choice for electricians or anyone working in environments with a risk of electrical hazards.

Second, they are thermally non-conductive. They do not transfer cold or heat as readily as metal, making them far more comfortable for work in extremely hot or cold weather conditions.

Convenience in Secure Environments

The non-metallic nature of composite toes means they will not set off metal detectors. This is a significant convenience for workers who must frequently pass through security checkpoints.

Understanding the Trade-offs: Composite vs. Metal

While composite materials offer clear benefits, it is crucial to understand where they differ from metal options like steel and alloy to make an informed safety decision.

Impact and Compression Resistance

This is the most critical trade-off. While all certified safety toes must meet specific ASTM safety standards, steel generally offers the highest level of protection against extreme impact and compression.

Composite toes provide certified protection, but after a significant impact, they may not offer the same level of structural integrity as steel for subsequent impacts. Steel can often bend but remain intact, whereas a composite cap is more likely to be compromised after one major event.

Material Composition and Modern Advancements

Modern nano-composite and carbon fiber technologies have allowed composite caps to become much stronger and thinner than earlier versions. This reduces the bulkiness that was once a drawback and provides more room in the toe box for a comfortable fit.

A Quick Look at Steel and Alloy

Steel toes remain the industry standard for heavy-duty protection. They offer the greatest resistance to impact and cracking but are heavy and conduct both electricity and temperature.

Alloy toes, made from materials like aluminum or titanium, provide a middle ground. They are lighter than steel while still offering excellent impact protection, but they remain metallic and are therefore conductive.

Making the Right Choice for Your Work

Selecting the correct safety toe requires you to prioritize the most common risks and requirements of your job.

- If your primary focus is maximum impact protection in heavy industrial or construction zones: Classic steel toes provide the most robust defense against crushing forces.

- If your primary focus is safety from electrical hazards or comfort in extreme temperatures: Composite toes are the definitive choice due to their non-conductive properties.

- If your primary focus is all-day comfort and you frequently pass through metal detectors: Composite toes offer the best combination of lightness and convenience.

- If you want a balance of lightweight comfort and high protection without non-metallic needs: Alloy toes are an excellent middle ground, offering near-steel protection at a lower weight.

Ultimately, choosing the right safety toe is an exercise in matching the tool to the task for optimal safety and comfort.

Summary Table:

| Feature | Composite Toe | Steel Toe | Alloy Toe |

|---|---|---|---|

| Primary Material | Kevlar, Carbon Fiber, Plastic | Steel | Aluminum, Titanium |

| Weight | Lightest (~30% lighter than steel) | Heaviest | Lighter than steel |

| Impact/Compression Resistance | Meets ASTM standards, but less than steel for extreme forces | Highest | High, near-steel level |

| Electrical Hazard Protection | Non-conductive (Ideal) | Conductive | Conductive |

| Thermal Insulation | Non-conductive (Ideal for extreme temps) | Conducts heat/cold | Conducts heat/cold |

| Metal Detector Friendly | Yes | No | No |

Need Safety Footwear Tailored to Your Specific Hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots with composite, steel, and alloy toes.

We help you ensure worker safety and comfort by providing the right footwear for the job.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- Why is it necessary to balance safety shoe protection with flexibility? Optimize Worker Comfort and Agility

- What are the protective functions of safety footwear and respirators in mitigating chemical exposure? Expert PPE Guide

- How can material selection mitigate skin injuries caused by the physical pressure of protective equipment? Key Strategies

- How does RFID technology improve Supply Chain Agility in safety shoe manufacturing? Master Real-Time Boot Production

- What materials are used in composite safety footwear? Choose the Right Protection for Your Work Environment

- How does professional foot protection prevent fractures? Advanced Shielding and Impact Dissipation

- What is the role of shock absorption in safety footwear? Protect Your Body from Repetitive Impact

- How does screening PET/PA blend ratios benefit safety shoe linings? Achieve Zero Charge & Anti-Static Safety