Ultimately, understanding OSHA safety shoe standards is about risk management. It ensures your organization meets federal legal requirements for worker safety while providing footwear scientifically tested to protect against specific, identified workplace hazards like impact, compression, and electrical shock.

The core principle is simple: OSHA mandates that employers provide foot protection, but the ASTM F2413 standard defines how that protection is tested and certified. Understanding the codes within this standard is the only way to match the right shoe to the right hazard.

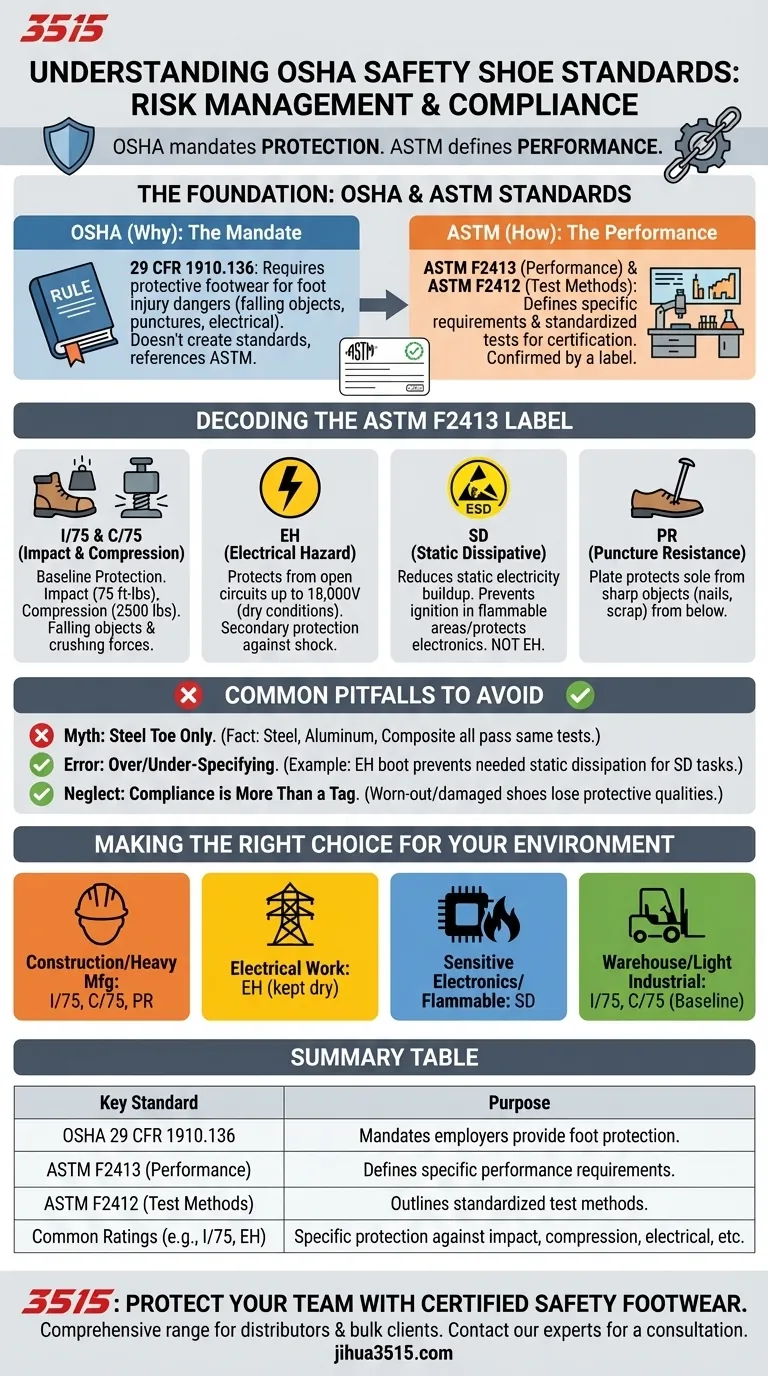

The Foundation: OSHA and ASTM Standards

To properly protect your team, you must understand how the regulatory body (OSHA) and the standards organization (ASTM) work together. They serve two different but connected purposes.

OSHA's Mandate: The "Why"

The Occupational Safety and Health Administration (OSHA) sets the legal requirement for workplace safety. For foot protection, OSHA standard 29 CFR 1910.136 is the key.

This regulation mandates that employers ensure employees use protective footwear when working in areas with dangers of foot injuries. These dangers include falling or rolling objects, objects piercing the sole, and electrical hazards.

OSHA does not create the specific performance standards for the shoes themselves. Instead, it incorporates by reference the standards developed by organizations like the American Society for Testing and Materials (ASTM).

ASTM's Role: The "How"

ASTM International develops the technical standards. ASTM F2413 is the current standard specification for performance requirements for protective footwear, while ASTM F2412 is the standard for the test methods.

A shoe that complies with OSHA's requirements will be certified as meeting the ASTM F2413 standard. This is confirmed by a label inside the shoe that details its specific protections.

Decoding the ASTM F2413 Label

The label inside a safety shoe is not just for show; it's a technical data sheet. Understanding its codes is critical for ensuring proper protection.

I/75 and C/75: Impact and Compression

This is the most fundamental rating for safety-toe footwear.

- I/75 signifies the shoe protects the toes from an impact of 75 foot-pounds.

- C/75 means it protects against a compressive load of 2,500 pounds.

This is the baseline protection against falling objects and crushing forces from rolling equipment.

EH: Electrical Hazard Resistance

EH-rated footwear is designed to protect the wearer from open electrical circuits of up to 18,000 volts under dry conditions.

The outsole is engineered to be a secondary source of protection, significantly reducing the potential for electric shock. This is critical for electricians and maintenance workers.

SD: Static Dissipative

SD footwear is designed to reduce the buildup of static electricity in the body.

This is crucial in environments where a static discharge could ignite flammable materials or damage sensitive electronic components. It is not the same as EH-rated footwear and the two should never be confused.

PR: Puncture Resistance

A PR rating indicates a puncture-resistant plate is positioned in the sole of the shoe to protect against sharp objects like nails or scrap metal from piercing the foot from below.

This is essential on construction sites, in recycling centers, and in manufacturing facilities where floor debris is common.

Common Pitfalls to Avoid

Simply mandating "safety shoes" is not enough. Misunderstanding the details can lead to compliance failures and, more importantly, injuries.

The Myth of "Steel Toe Only"

The protective toe cap required by ASTM F2413 can be made from steel, aluminum, or non-metallic composite materials. All materials must pass the exact same I/75 and C/75 tests.

The choice of material often comes down to secondary needs like weight, temperature transfer, or whether the environment requires non-metallic footwear (e.g., for passing through metal detectors).

Over-specifying vs. Under-specifying

Requiring EH-rated boots in an environment where static dissipation (SD) is needed is a critical error. The EH boot is designed to insulate, which would prevent static from dissipating and could increase risk.

Conversely, providing a standard I/75 C/75 boot to a roofer without Puncture Resistance (PR) leaves them exposed to nail hazards. Always match the specific ratings to the specific, identified hazards of the job.

Compliance is More Than a Tag

A worn-out shoe may no longer provide its stated level of protection. A deep cut in the sole of an EH boot compromises its electrical resistance.

A proper safety program includes not only selecting the right shoe but also training employees on how to inspect their footwear for wear and tear that could negate its protective qualities.

Making the Right Choice for Your Environment

Your goal is to align the footwear's certified protections with the real-world risks your employees face.

- If your primary focus is a construction site or heavy manufacturing: Prioritize footwear with I/75, C/75, and PR (Puncture Resistance) ratings.

- If your primary focus is electrical work or high-voltage maintenance: Mandate footwear with an EH (Electrical Hazard) rating and ensure it is kept in good, dry condition.

- If your primary focus is working with sensitive electronics or in flammable environments: Require SD (Static Dissipative) footwear to control electrostatic discharge.

- If your primary focus is general warehouse or light industrial work: A baseline I/75 and C/75 rated shoe is the minimum requirement to protect against falling items and rolling carts.

By moving beyond a generic requirement and focusing on the specific ASTM codes, you ensure your foot protection program is both compliant and genuinely effective.

Summary Table:

| Key OSHA/ASTM Standard | Purpose & Importance |

|---|---|

| OSHA 29 CFR 1910.136 | Mandates employers provide foot protection against workplace hazards. |

| ASTM F2413 (Performance) | Defines the specific performance requirements for protective footwear. |

| ASTM F2412 (Test Methods) | Outlines the standardized test methods to certify footwear. |

| Common Ratings (e.g., I/75, EH) | Specific codes indicating protection against impact, compression, electrical hazards, etc. |

Protect your team with the right safety footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring you get the precise ASTM-rated protection your workforce needs.

Let us help you build a compliant and effective safety program. Contact our experts today for a consultation on your specific requirements.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

People Also Ask

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data