In the modern workplace, protective footwear is specifically engineered to counter distinct environmental hazards. Common examples include steel-toe boots in warehouses to guard against rolling equipment and falling objects, non-conductive composite toe boots for electricians to prevent electrical shock, and puncture-resistant soles for workers on construction sites or in kitchens where sharp objects pose a threat.

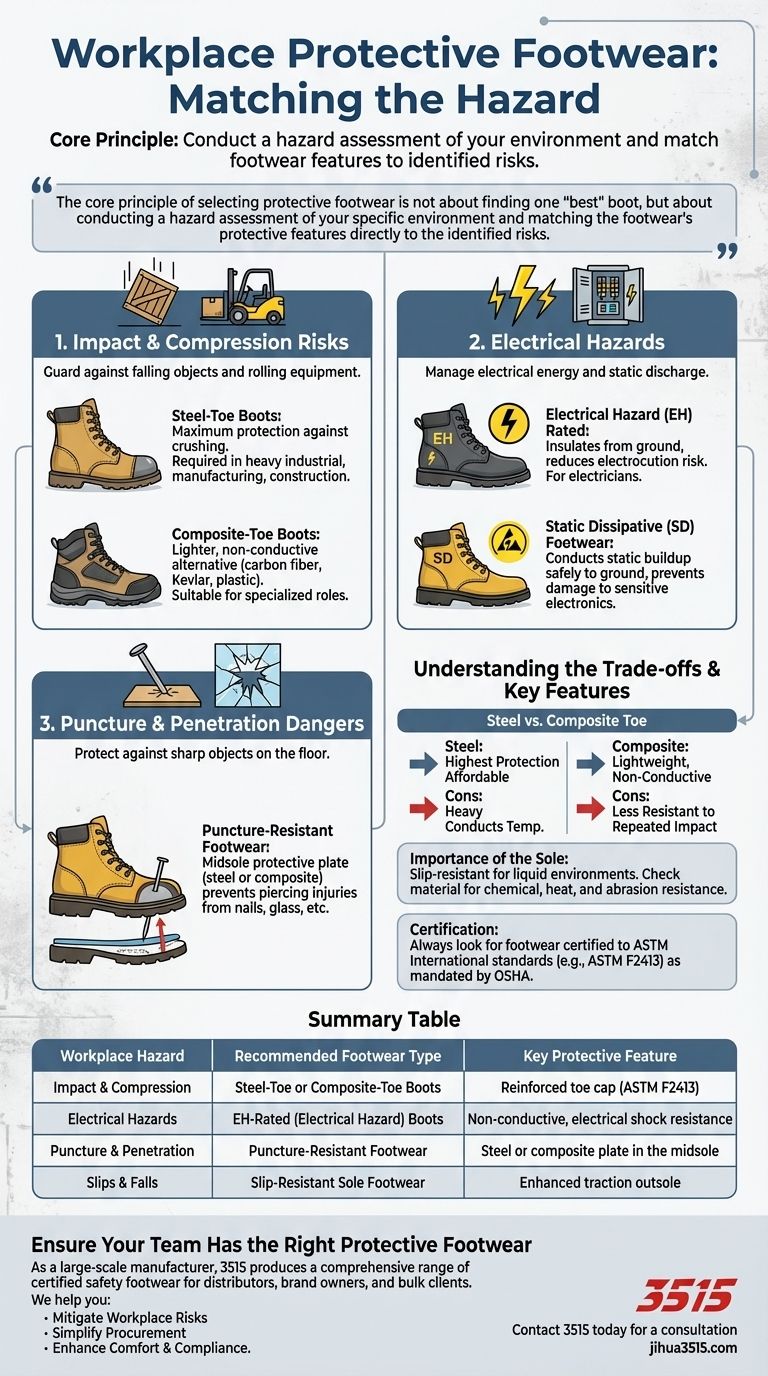

The core principle of selecting protective footwear is not about finding one "best" boot, but about conducting a hazard assessment of your specific environment and matching the footwear's protective features directly to the identified risks.

Matching the Hazard to the Footwear

Protective footwear is a critical piece of Personal Protective Equipment (PPE). The Occupational Safety and Health Administration (OSHA) mandates its use in environments with known foot injury risks. The key is to understand the type of risk first.

Impact and Compression Risks

For environments with heavy materials, rolling equipment like forklifts, or the risk of falling objects, the primary concern is impact and compression.

Steel-toe boots are the traditional standard for maximum protection against crushing forces. They are required in most heavy industrial, manufacturing, and construction settings.

Composite-toe boots, made from materials like carbon fiber, Kevlar, or plastic, offer an alternative. They are lighter and do not conduct electricity, making them suitable for certain specialized roles.

Electrical Hazards

Working near live circuits or in environments with sensitive electronics requires specialized footwear to manage electrical energy.

Electrical Hazard (EH) rated boots are designed to insulate the wearer from the ground, significantly reducing the chance of electrocution. These are essential for electricians and maintenance workers.

Static Dissipative (SD) footwear serves a different purpose. It is designed to safely conduct static electricity buildup from the body into the ground, preventing a sudden discharge that could damage sensitive electronic components.

Puncture and Penetration Dangers

Many work environments have sharp objects on the floor, from stray nails on a construction site to broken glass in a disposal facility.

Puncture-resistant footwear incorporates a protective plate in the midsole, typically made of steel or a flexible composite material. This plate prevents sharp objects from piercing the sole and injuring the foot.

Understanding the Trade-offs

Choosing the right footwear involves balancing protection, comfort, and job-specific requirements. No single feature is universally superior; it's always about the context of the work.

Steel Toe vs. Composite Toe

The most common decision point is between steel and composite toe caps.

Steel offers the highest level of protection against impact and compression and is often more affordable. However, it is heavier and conducts temperature, which can be uncomfortable in extreme cold or heat.

Composite toes are significantly lighter, do not conduct electricity or temperature, and won't set off metal detectors. Their primary trade-off is that they may not withstand the same level of repeated impact as steel.

Beyond the Toecap: The Importance of the Sole

While toe protection is critical, the sole of the footwear is equally important for overall safety.

A slip-resistant sole is crucial in environments with water, oil, or other liquids to prevent falls. Additionally, the material of the sole dictates its resistance to chemicals, heat, and abrasion.

The Role of Certification

Always look for footwear certified to meet ASTM International standards (e.g., ASTM F2413). This certification ensures the boot has been tested and proven to provide the level of protection it claims, a requirement enforced by OSHA.

Selecting the Right Footwear for Your Environment

Your final choice must be based on a clear-eyed assessment of your daily tasks and potential dangers.

- If your primary focus is protection from heavy objects: Steel-toe boots provide the most robust defense against impact and crushing forces.

- If your primary focus is working with live electricity: EH-rated, non-conductive footwear is a non-negotiable requirement for your safety.

- If your primary focus is navigating debris and sharp objects: Puncture-resistant soles are the most critical feature to prevent serious injury.

- If your primary focus is a combination of hazards: Look for footwear that integrates multiple features, such as a composite toe with an EH rating and a slip-resistant sole.

Ultimately, understanding the specific risks you face is the first and most important step in protecting yourself.

Summary Table:

| Workplace Hazard | Recommended Footwear Type | Key Protective Feature |

|---|---|---|

| Impact & Compression (e.g., falling objects) | Steel-Toe or Composite-Toe Boots | Reinforced toe cap (ASTM F2413) |

| Electrical Hazards (e.g., live circuits) | EH-Rated (Electrical Hazard) Boots | Non-conductive, electrical shock resistance |

| Puncture & Penetration (e.g., nails, glass) | Puncture-Resistant Footwear | Steel or composite plate in the midsole |

| Slips & Falls (e.g., oil, water) | Slip-Resistant Sole Footwear | Enhanced traction outsole |

Ensure Your Team Has the Right Protective Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial boots and shoes, including steel-toe, composite-toe, EH-rated, and puncture-resistant models, all designed to meet or exceed ASTM/OSHA standards.

We help you:

- Mitigate Workplace Risks: Equip your workforce with footwear specifically engineered for their unique hazards.

- Simplify Procurement: Source a wide variety of compliant safety boots from a single, reliable manufacturer.

- Enhance Comfort & Compliance: Offer durable, comfortable options that workers will wear, ensuring adherence to safety protocols.

Protect your most valuable asset—your people. Let's discuss your specific needs and how our manufacturing expertise can support your safety goals.

Contact 3515 today for a consultation

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- How do safety shoes protect against electrical hazards? Essential Features for Workplace Safety

- What is the ANSI standard for safety footwear? It's Now ASTM F2413 for OSHA Compliance

- What quality control measures are taken in safety shoes manufacturing? Ensure Maximum Protection & Compliance

- What types of specialized protective footwear are available for deep liquid environments? Choose the Right Waders for Maximum Safety

- What does the ASTM F2413-18 standard cover for safety footwear? A Guide to Workplace Toe Protection

- What is the primary function of a cooling system in safety shoe production? Ensure Structural Integrity and Speed

- What is the purpose of using a shoe spray on work shoes and socks? Enhance Hygiene and Safety

- Which testing dimensions does a fall-induction experimental platform provide? 4 Key Metrics for Safety Footwear R&D