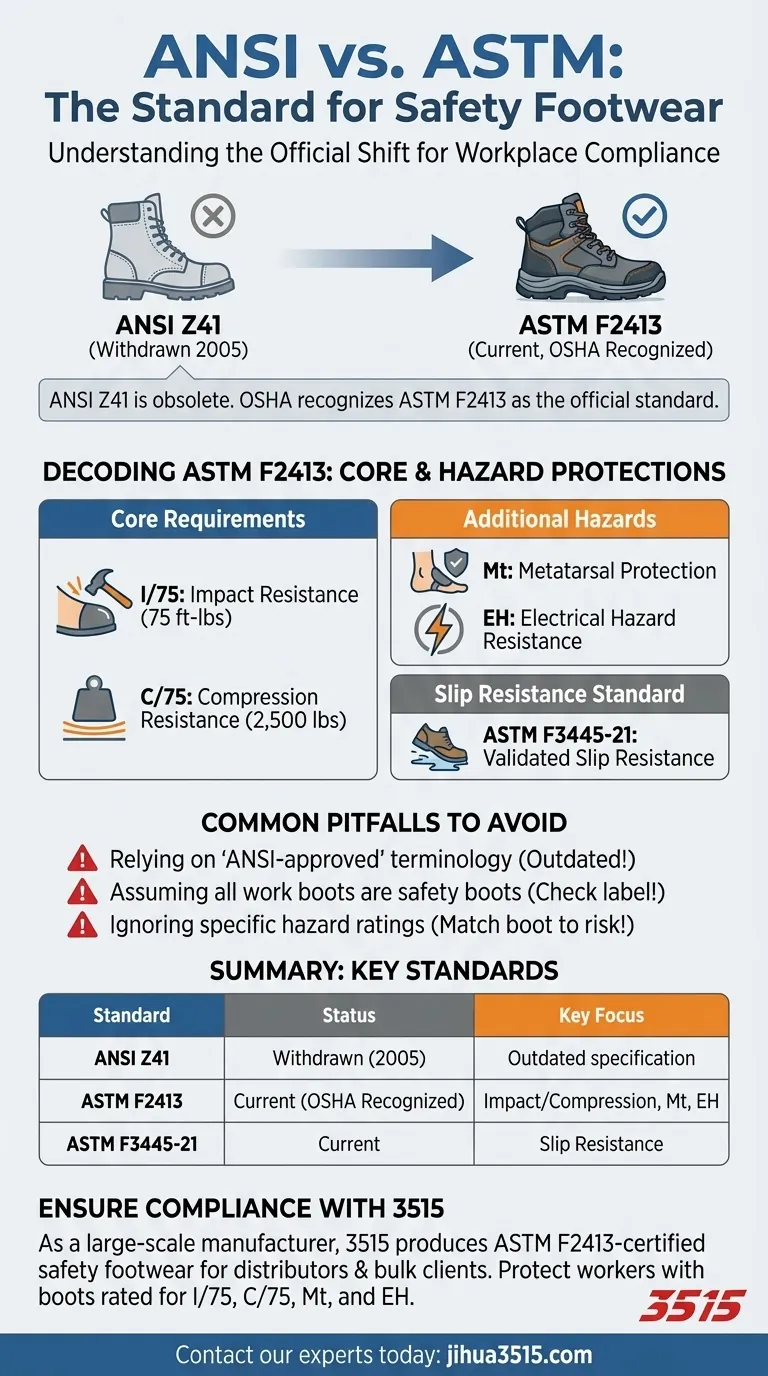

While the term is still widely used, there is no longer an active ANSI standard for safety footwear. The former ANSI Z41 standard was replaced in 2005 by the ASTM F2413 standard, which is now the official U.S. benchmark for performance requirements for protective footwear.

The core issue isn't finding an "ANSI-approved" boot, but understanding that the industry has transitioned to the ASTM F2413 standard. This is the specific safety specification that the U.S. Occupational Safety and Health Administration (OSHA) recognizes for workplace compliance.

The Evolution from ANSI to ASTM

To ensure you're specifying and using correctly certified footwear, it's critical to understand this official shift in standards. What was once known as the ANSI standard is now managed by ASTM International.

### From ANSI Z41 to Today's Standard

The old standard, ANSI Z41, was officially withdrawn and replaced in 2005.

Any footwear labeled as compliant with only ANSI Z41 is referencing an outdated specification. Modern, compliant safety footwear must be certified to the current ASTM standard.

### What ASTM F2413 Covers

ASTM F2413 establishes the minimum performance requirements for safety footwear to protect against a variety of workplace hazards.

The standard outlines testing procedures for several key categories, including impact resistance, compression resistance, and metatarsal protection.

### The Critical Role of OSHA

The U.S. Occupational Safety and Health Administration (OSHA) mandates that employers protect workers from foot injuries.

OSHA’s guidelines do not create a separate standard; instead, they require that safety footwear meets the criteria established by ASTM F2413. This makes ASTM compliance essential for meeting federal safety regulations.

Decoding Safety Footwear Requirements

Understanding the markings and requirements of ASTM F2413 allows you to select the precise protection needed for a specific job, rather than relying on generic "safety toe" boots.

### Core Requirements: Impact and Compression

The most fundamental protections are for the toe area. Compliant footwear must have a built-in protective toe cap.

These toe caps are tested for both impact (I) and compression (C) resistance. The highest rating, 75, indicates the toe cap can withstand 75 foot-pounds of impact and 2,500 pounds of compression.

### Additional Hazard Protections

Beyond the toe cap, ASTM F2413 includes codes for specific hazards. These are clearly marked on the shoe's label.

Common ratings include Mt for metatarsal protection, which guards the top of the foot, and EH for Electrical Hazard resistance, which protects against open circuits of 600 volts or less.

### The New Standard for Slip Resistance

A separate but equally important standard is ASTM F3445-21.

This recent standard was created to provide a universal specification for testing slip resistance. Footwear meeting this standard offers a validated level of protection on wet or otherwise slick surfaces.

Common Pitfalls to Avoid

Navigating safety standards can be confusing. Focusing on the current, correct specifications is the only way to ensure true compliance and worker safety.

### Relying on Outdated Terminology

Do not search for or specify "ANSI-approved" footwear. This term is obsolete and may lead you to non-compliant or older products.

Always look for the ASTM F2413 certification on the product label or technical data sheet.

### Assuming All Work Boots Are Safety Boots

A sturdy-looking boot is not necessarily a safety boot.

Unless it has been tested and certified to meet the specific performance criteria of ASTM F2413, it does not qualify as official protective footwear and will not be OSHA compliant.

### Ignoring Specific Hazard Ratings

A boot rated for impact (I/75) and compression (C/75) is not automatically suitable for an electrician.

You must match the specific hazard ratings (EH, Mt, etc.) to the known risks of the work environment.

Making the Right Choice for Your Goal

Selecting the right footwear requires matching the boot's specific ASTM ratings to the hazards of your workplace.

- If your primary focus is general construction or manufacturing: Ensure footwear is, at minimum, rated ASTM F2413 with I/75 and C/75 for impact and compression resistance.

- If your primary focus is working around heavy, rolling objects: Prioritize boots with an additional Metatarsal (Mt) guard rating for protection over the top of the foot.

- If your primary focus is electrical work: The boot must have an Electrical Hazard (EH) rating to protect against shock from live circuits.

- If your primary focus is preventing slips in wet or oily areas: Look for footwear that specifically states compliance with the ASTM F3445-21 slip-resistance standard.

Ultimately, understanding the current ASTM standards empowers you to make an informed decision that ensures true safety and compliance.

Summary Table:

| Standard | Status | Key Focus |

|---|---|---|

| ANSI Z41 | Withdrawn (2005) | Outdated specification |

| ASTM F2413 | Current (OSHA Recognized) | Impact/Compression, Metatarsal, Electrical Hazard |

| ASTM F3445-21 | Current | Slip Resistance on wet/oily surfaces |

Ensure Your Team Wears the Right Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-certified safety footwear for distributors, brand owners, and bulk clients. We help you ensure OSHA compliance and protect workers from specific job hazards with boots rated for Impact (I/75), Compression (C/75), Metatarsal (Mt), and Electrical Hazard (EH) protection.

Let's discuss your specific safety requirements: Contact our experts today to find the perfect compliant footwear solution for your needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What shoes to wear for a security job? Durable, Protective Footwear for Long Shifts

- How do slip-resistant outsoles in safety shoes mitigate the risk of physical imbalance? Boost Grip & Prevent Falls

- How do anti-slip outsoles and orthopedic heel designs contribute to footwear safety? Enhance Traction & Stability

- Why is it important to prioritize safety and comfort in work footwear? Boost Performance & Prevent Injury

- What role do advanced safety technical features play? Elevating High-Performance Safety Shoe Engineering

- Why are metal balls filled into insulating shoes during testing? Ensuring Precise Dielectric Safety Assessments

- How is AI utilized in the design of outdoor and safety footwear? Harnessing Big Data for Market-Driven Shoe Innovation

- What is the importance of understanding OSHA safety shoe standards? Ensure Compliance and Protect Your Workforce