At their core, the most common complaints associated with wearing steel toe boots are physical discomfort and pain. These issues manifest as sore feet, heel and ankle pain, blisters, and general fatigue, primarily caused by the boots' rigid structure, improper fit, and significant weight.

While steel toe boots are non-negotiable for protection in hazardous environments, the discomfort they cause is not. Most common complaints stem from a mismatch between the boot and the wearer's foot, a problem that can be systematically addressed and solved.

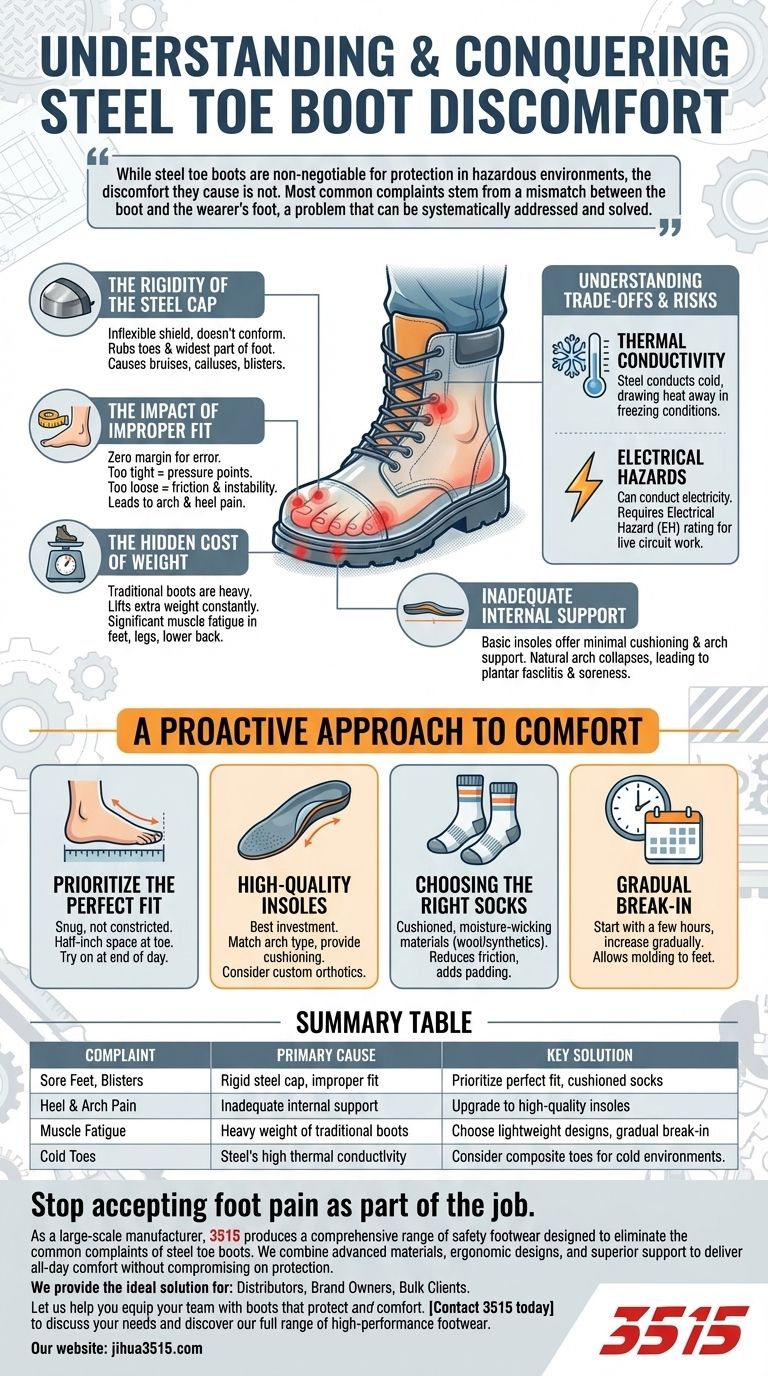

Deconstructing the Discomfort: Why Steel Toes Cause Problems

Understanding the source of pain is the first step toward finding a solution. The protective design of these boots introduces several factors that can lead to significant discomfort if not managed correctly.

The Rigidity of the Steel Cap

The steel toe cap is an inflexible shield. Its primary job is to resist impact and compression, not to conform to your foot.

This rigidity means the cap can rub against the top of your toes and the widest part of your foot, leading directly to bruises, calluses, and blisters over time.

The Impact of Improper Fit

An incorrect fit is the single largest contributor to foot pain. A boot that is too tight creates constant pressure points, while a boot that is too loose allows the foot to slide, causing friction and instability.

Because of the rigid toe box, there is zero margin for error in sizing. A poor fit prevents the foot from sitting correctly on the boot's supportive structures, leading to arch and heel pain.

The Hidden Cost of Weight

Traditional steel toe boots are heavy. Lifting this extra weight with every step throughout a long workday leads to significant muscle fatigue in your feet, legs, and even your lower back.

This constant strain accumulates, making feet feel sore and tired long before the workday is over.

Inadequate Internal Support

Most work boots come with basic, flat insoles that offer minimal cushioning and almost no arch support.

Without proper support, your foot's natural arch can collapse under stress, leading to conditions like plantar fasciitis and generalized foot soreness.

Understanding the Trade-offs and Risks

While modern designs have improved comfort, certain inherent characteristics of steel toe boots present trade-offs that wearers must be aware of.

Thermal Conductivity

Steel is an excellent conductor of temperature. In cold environments, the steel cap can become extremely cold, drawing heat away from your toes and causing significant discomfort.

This makes them less ideal for prolonged work in freezing conditions compared to boots with composite safety toes.

Electrical Hazards

Standard steel toe boots can conduct electricity. While this is not a risk in most environments, it is a critical danger for anyone working near live electrical circuits.

For these jobs, boots must have a specific Electrical Hazard (EH) rating to provide the necessary insulation and protection.

A Proactive Approach to Comfort

You do not have to accept foot pain as a necessary evil of workplace safety. A few strategic choices can dramatically improve your daily experience.

Prioritizing the Perfect Fit

Getting the right fit is the most critical step. Your foot should be snug but not constricted, with about a half-inch of space between your longest toe and the end of the boot.

Always try on boots at the end of the day when your feet are slightly swollen to get the most accurate measurement.

The Power of High-Quality Insoles

Upgrading your boot's stock insoles is the single best investment you can make for comfort. Look for insoles that match your arch type and provide ample cushioning.

For those with specific foot issues, custom orthotics can provide tailored support that prevents pain and fatigue.

Choosing the Right Socks

The right socks act as a critical interface between your foot and the boot. Wear cushioned, moisture-wicking socks made from materials like wool or synthetic blends.

This helps manage sweat, reduce friction, and provide an extra layer of padding against pressure points.

The Importance of Gradual Break-in

Never wear a brand-new pair of boots for a full workday. Wear them for a few hours at a time initially, gradually increasing the duration to allow the leather and internal components to mold to your feet.

Making the Right Choice for Your Feet

Your specific work environment and physical needs should dictate your priorities when selecting and customizing your boots.

- If your primary focus is all-day comfort for long shifts: Prioritize lightweight designs and immediately invest in high-quality, supportive insoles that match your arch type.

- If your primary focus is working in cold environments: Consider composite toe boots, which do not conduct cold, or ensure your steel toe boots are well-insulated.

- If your primary focus is preventing blisters and rubbing: Ensure a perfect fit is your top priority and pair your boots with moisture-wicking, cushioned socks.

By understanding the causes of discomfort, you can take control and build a system of foot protection that is both safe and comfortable.

Summary Table:

| Common Complaint | Primary Cause | Key Solution |

|---|---|---|

| Sore Feet, Blisters | Rigid steel cap, improper fit | Prioritize perfect fit, use cushioned socks |

| Heel & Arch Pain | Inadequate internal support | Upgrade to high-quality, supportive insoles |

| Muscle Fatigue | Heavy weight of traditional boots | Choose lightweight designs, gradual break-in |

| Cold Toes | Steel's high thermal conductivity | Consider composite toes for cold environments |

Stop accepting foot pain as part of the job.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear designed to eliminate the common complaints of steel toe boots. We combine advanced materials, ergonomic designs, and superior support to deliver all-day comfort without compromising on protection.

We provide the ideal solution for:

- Distributors seeking reliable, high-comfort products for their customers.

- Brand Owners looking for durable, customizable safety footwear.

- Bulk Clients needing consistent quality and comfort for their entire workforce.

Let us help you equip your team with boots that protect and comfort. Contact 3515 today to discuss your needs and discover our full range of high-performance footwear.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

People Also Ask

- What are the primary purposes of steel toe shoes? Essential Foot Protection for Hazardous Workplaces

- What are the 5 main protections offered by steel toe boots? A Guide to Workplace Foot Safety

- What are steel-toed shoes and what industries use them? Essential Foot Protection for Hazardous Work

- Do moc toe boots have steel toe? Get Durable, Safety-Compliant Footwear

- Why are precision metal processing and industrial heat treatment equipment essential in the production of toe caps?

- How do composite toe boots compare to steel toe boots? A Guide to Maximum Safety & Comfort

- What are the different types of steel toe work boots? Choose the Right Boot for Your Job

- What are the disadvantages of wearing steel-toe boots? Heavy Weight, Discomfort & Safety Risks