In short, steel-toed shoes are a type of personal protective equipment (PPE) with a reinforced steel cap integrated into the toe area. They are designed to protect the feet from impact and compression injuries. The use of this footwear is mandated across any industry where workers face a significant risk from falling objects or heavy machinery.

The core principle behind steel-toed footwear is not about a specific job title, but about mitigating a specific workplace hazard: the risk of crushing or impact injuries to the feet from heavy objects, machinery, or falling materials.

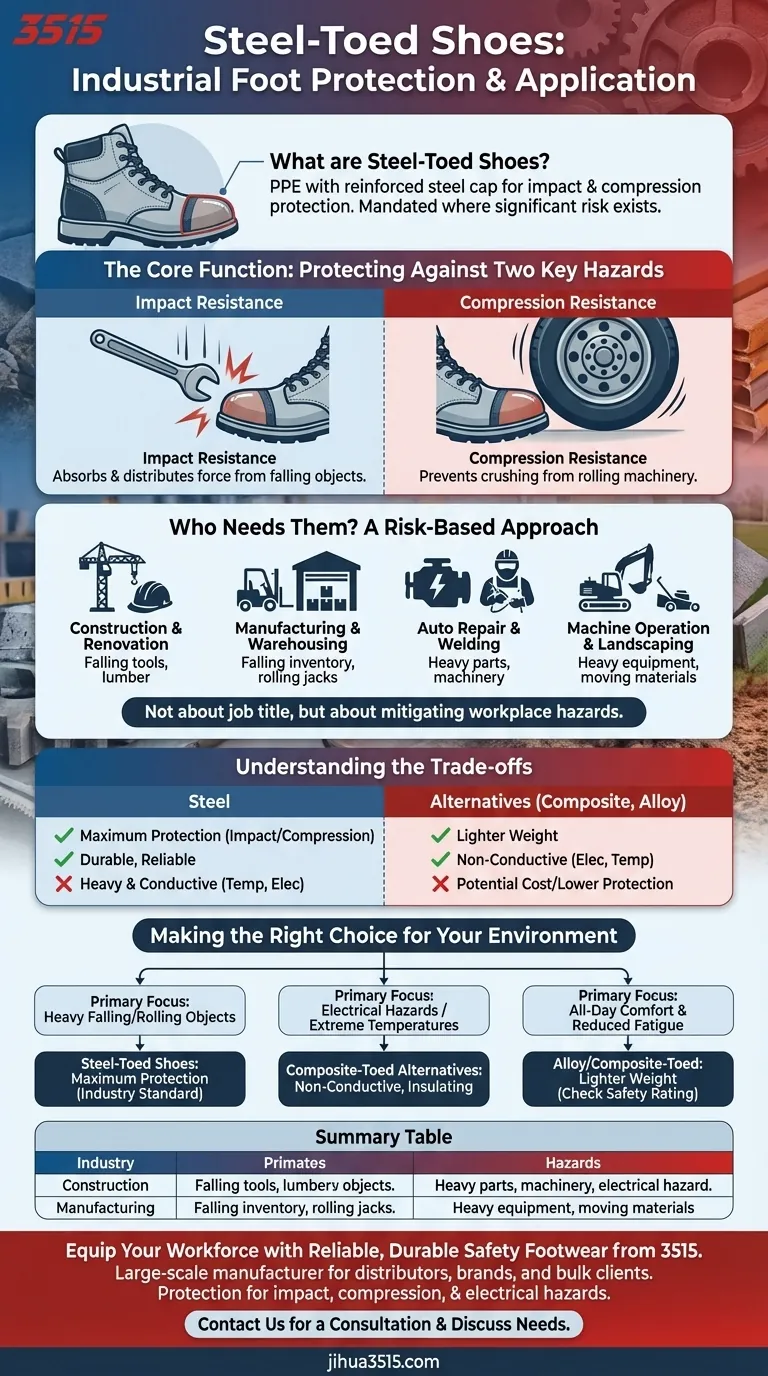

The Core Function: Protecting Against Two Key Hazards

Understanding why steel-toed shoes are required comes down to the two primary types of threats they are engineered to defeat. The steel reinforcement serves as a rigid shield for one of the most vulnerable parts of the body.

Impact Resistance

The steel cap is designed to withstand a direct blow from a heavy falling object, such as a dropped tool or building material. The cap absorbs and distributes the force of the impact across the entire front of the boot, preventing the force from being concentrated on the toes.

Compression Resistance

This protects against crushing injuries that occur when a heavy object rolls over the foot. This is a common hazard in environments with forklifts, pallet jacks, or heavy carts where a wheel could run over a worker's foot. The steel cap prevents the toe box from collapsing under the weight.

Who Needs Steel-Toed Footwear? A Risk-Based Approach

While many industries have broad requirements, the need for this specific PPE is always tied to the presence of impact and compression hazards on the job site.

Construction and Renovation

On these sites, workers are constantly exposed to falling tools, lumber, bricks, and other construction materials. The environment is dynamic and presents a high risk of foot injuries from dropped objects.

Manufacturing and Warehousing

These environments are defined by the movement of heavy goods and machinery. Workers are at risk from falling inventory, rolling pallet jacks, and the operation of heavy equipment like forklifts.

Auto Repair and Welding

Mechanics and welders frequently handle heavy vehicle parts, such as engine blocks, transmissions, and wheels. Dropping one of these components can cause severe foot injury without proper protection.

Machine Operation and Landscaping

Operators of heavy machinery and landscaping equipment face risks from the equipment itself and the materials they move. This includes everything from lawnmowers to heavy-duty earthmovers.

Understanding the Trade-offs

While steel provides exceptional protection, it's important to understand its specific characteristics, as it is not the only material used in safety footwear.

The Benefit of Steel: Maximum Protection

Steel generally offers the highest level of protection against impact and compression for its cost. It is a time-tested, durable, and reliable material that has been the industry standard for decades.

The Drawback of Steel: Weight and Conductivity

Steel is heavier than modern alternatives like composite materials (e.g., Kevlar, carbon fiber) or aluminum alloys. It also conducts temperature, making steel-toed boots feel colder in winter and hotter in summer. Crucially, steel conducts electricity, making it unsuitable for certain jobs where electrical hazards are a primary concern.

Making the Right Choice for Your Environment

Your decision should be based on a clear-eyed assessment of the risks you face daily.

- If your primary focus is protection against heavy falling or rolling objects: Traditional steel-toed shoes are the proven industry standard for maximum impact and compression resistance.

- If your primary focus is working around electrical hazards or in extreme temperatures: You should investigate composite-toed alternatives, which do not conduct electricity, heat, or cold.

- If your primary focus is all-day comfort and reduced fatigue: Lighter-weight alloy or composite-toed shoes may be a better fit, provided they meet the required safety rating for your job.

Ultimately, selecting the right protective footwear is about matching the equipment to the specific, predictable risks of your daily work.

Summary Table:

| Industry | Primary Hazards Addressed |

|---|---|

| Construction & Renovation | Falling tools, lumber, bricks |

| Manufacturing & Warehousing | Falling inventory, rolling equipment |

| Auto Repair & Welding | Heavy vehicle parts, machinery |

| Machine Operation & Landscaping | Heavy equipment, moving materials |

Equip your workforce with reliable, durable safety footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of steel-toed and composite-toed boots for distributors, brand owners, and bulk clients. Ensure your team has the right protection for impact, compression, and electrical hazards. Contact us today for a consultation and to discuss your specific needs.

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- Why is specialized personal protective equipment required for specific industries? Enhancing Safety in Heavy Industry

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance