While essential for protection, steel-toe boots come with several significant disadvantages you must consider. Their primary drawbacks are their heavy weight, poor temperature regulation, the risk they pose around electrical hazards, and their inconvenience in security-sensitive areas.

The core issue with steel-toe boots is that their underlying technology, while effective for impact protection, introduces notable trade-offs in comfort and safety that have been addressed by more modern alternatives like composite-toe boots.

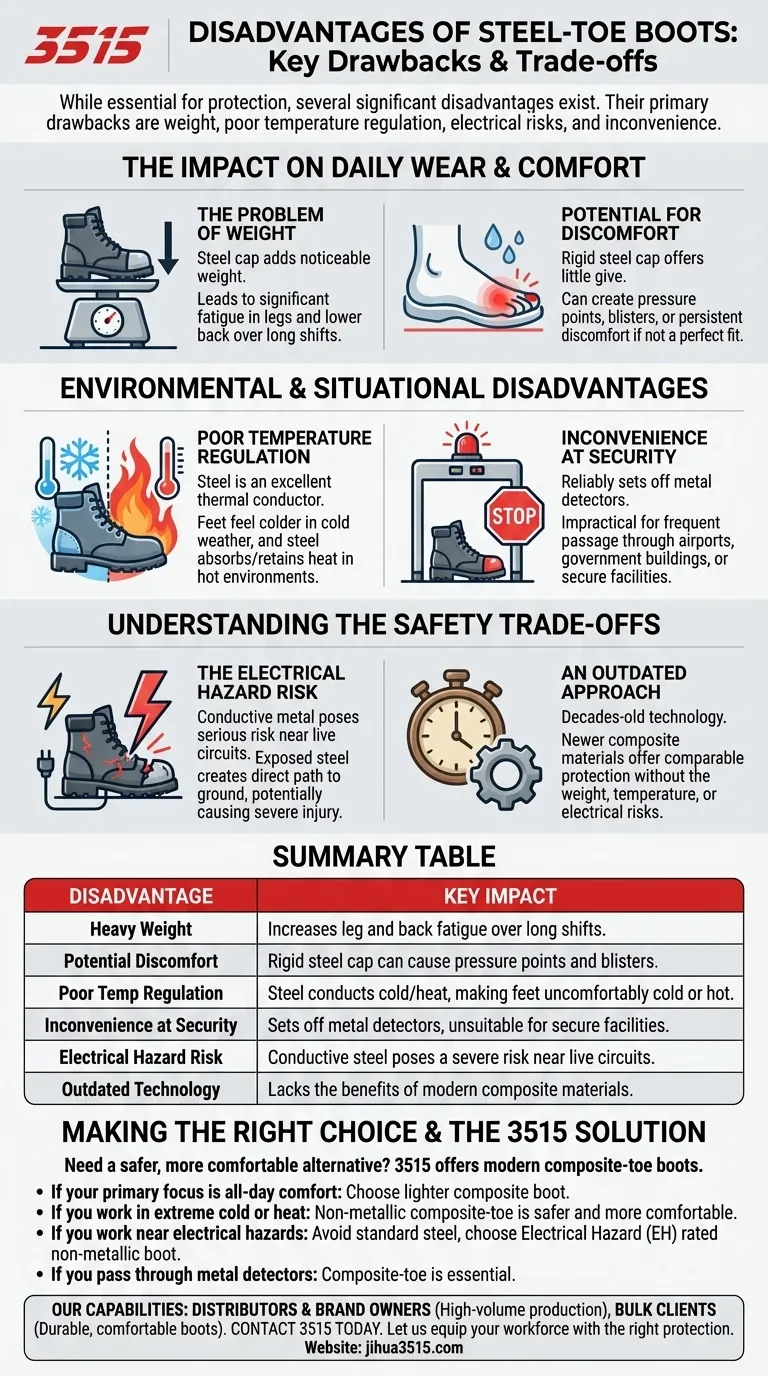

The Impact on Daily Wear and Comfort

For individuals who spend long shifts on their feet, the physical characteristics of steel-toe boots can become a major issue.

The Problem of Weight

The steel cap adds noticeable weight to each boot. Over the course of a day, this extra weight can lead to significant fatigue in the legs and lower back.

Potential for Discomfort

The rigid nature of the steel cap means there is very little give. If the boots don't fit perfectly, this can create pressure points on the toes and top of the foot, potentially leading to blisters or persistent discomfort.

Environmental and Situational Disadvantages

Beyond pure comfort, the material properties of steel create challenges in specific work environments.

Poor Temperature Regulation

Steel is an excellent thermal conductor. This means in cold weather, the steel cap draws heat away from your feet, making them feel much colder. Conversely, in hot environments, it can absorb and retain heat.

Inconvenience at Security Checkpoints

The steel in the boots will reliably set off metal detectors. This makes them impractical for anyone who must frequently pass through security screenings at airports, government buildings, or secure facilities.

Understanding the Safety Trade-offs

While designed for safety, the very material that protects your toes can introduce other risks.

The Electrical Hazard Risk

Steel is a conductive metal. This presents a serious risk for electricians or anyone working near live circuits. If the boot becomes damaged and the steel cap is exposed, it can create a direct path for electricity to ground, potentially causing severe injury.

An Outdated Approach

While strong, steel-toe technology is decades old. Newer materials, such as those used in composite-toe boots, now offer comparable impact protection without the downsides of weight, temperature conductivity, or electrical risk.

Making the Right Choice for Your Environment

To select the appropriate footwear, you must weigh these disadvantages against the specific demands of your job.

- If your primary focus is extreme impact protection at a low cost: Steel-toe remains a durable and traditional choice.

- If your primary focus is all-day comfort and reducing fatigue: The heavy weight is a significant drawback, and a lighter composite boot is a better option.

- If you work in extreme cold or heat: The thermal conductivity of steel makes non-metallic, composite-toe boots a far more comfortable and safer choice.

- If you work near potential electrical hazards: You must avoid standard steel-toe boots and choose a non-metallic boot specifically rated for Electrical Hazard (EH) protection.

- If you regularly pass through metal detectors: A composite-toe boot is essential to avoid constant inconvenience.

Ultimately, choosing the right safety boot requires matching the boot's material and features to your specific daily tasks and environment.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Heavy Weight | Increases leg and back fatigue over long shifts. |

| Potential Discomfort | Rigid steel cap can cause pressure points and blisters. |

| Poor Temperature Regulation | Steel conducts cold/heat, making feet uncomfortably cold or hot. |

| Inconvenience at Security | Sets off metal detectors, unsuitable for secure facilities. |

| Electrical Hazard Risk | Conductive steel poses a severe risk near live circuits. |

| Outdated Technology | Lacks the benefits of modern composite materials. |

Need a safer, more comfortable alternative to steel-toe boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of modern safety footwear, including lightweight composite-toe boots that eliminate the common disadvantages of steel. We provide superior protection without the heavy weight, temperature issues, or electrical risks.

Our capabilities are ideal for:

- Distributors & Brand Owners seeking reliable, high-volume production of advanced safety footwear.

- Bulk Clients needing durable, comfortable boots tailored to specific work environments.

Let us help you equip your workforce with the right protection. Contact 3515 today to discuss your footwear needs and explore our full product range.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety

- What is the purpose of steel-toe moc toe boots? Achieve All-Day Safety and Comfort

- How does the structural design of industrial-grade safety shoes provide protection? Engineering Foot Health at Work

- Why are safety shoes mandatory for historical stone cleaning? Essential Gear for Restoration Projects

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection