At their core, steel toe boots offer five primary layers of protection for workers in hazardous environments. They are engineered to shield your feet from impact from falling objects, punctures from below, electrical shocks, slips and falls, and the effects of extreme weather.

The term "steel toe boot" is slightly misleading. It's more accurate to think of it as a comprehensive safety system where the reinforced toe cap is just the most famous component, working alongside a specialized sole, upper materials, and construction to provide all-around protection.

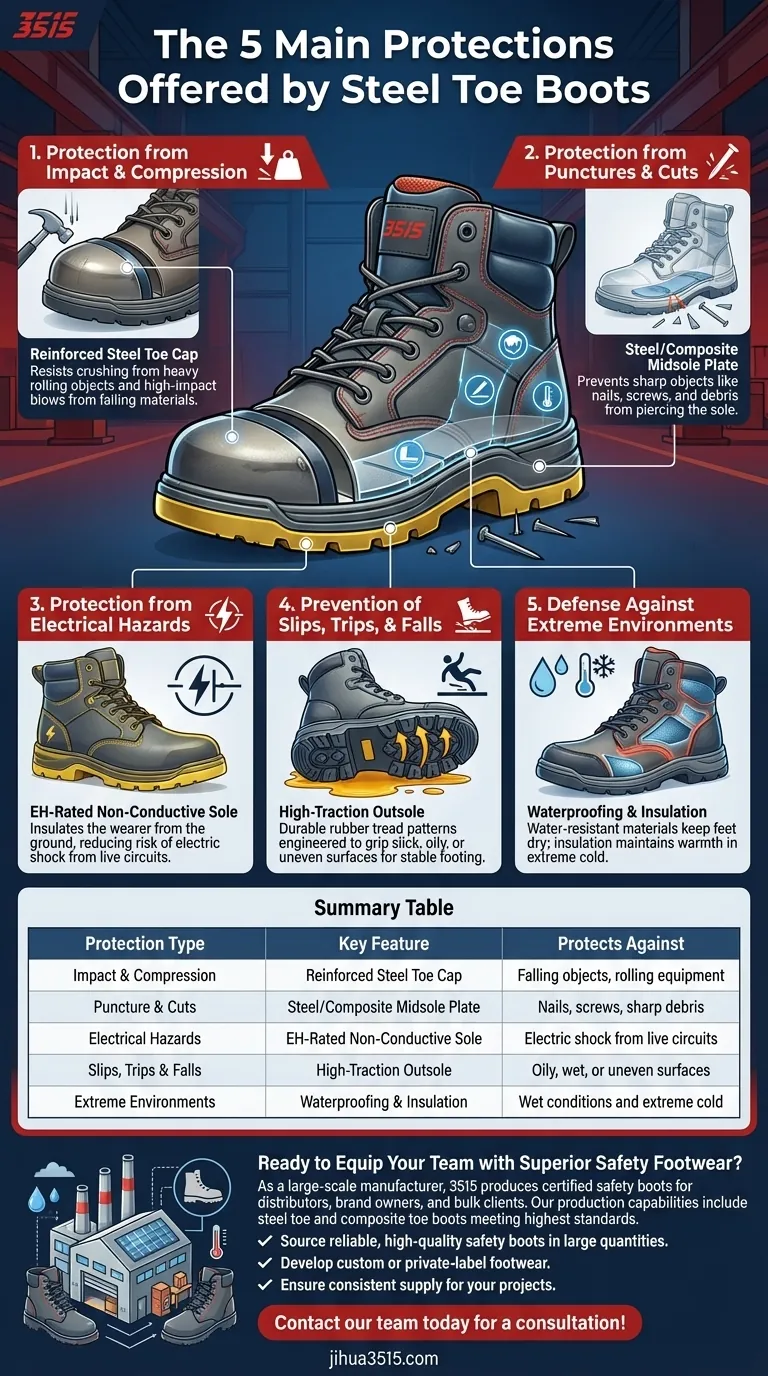

The 5 Core Layers of Protection

Each element of a safety boot is designed to mitigate a specific type of workplace risk. Understanding these functions helps you appreciate the footwear not as a simple accessory, but as essential personal protective equipment (PPE).

Protection from Impact and Compression

This is the most well-known feature of a steel toe boot. A rigid steel cap is built into the toe box of the boot.

This cap is designed to resist crushing forces from heavy rolling objects, like carts or equipment, and high-impact blows from falling materials, such as tools or construction debris.

Protection from Punctures and Cuts

Many job sites have sharp objects on the ground, such as nails, screws, or scrap metal.

To counter this, many safety boots include a puncture-resistant plate, often made of steel or a composite material, that is integrated into the midsole. This plate prevents sharp objects from piercing the sole and injuring your foot.

Protection from Electrical Hazards

This is a frequently misunderstood feature. While steel itself is a conductor, boots rated for Electrical Hazard (EH) protection are specifically designed to be a secondary source of protection.

EH-rated boots feature non-conductive soles and heels that can insulate the wearer from the ground, significantly reducing the risk of electric shock when stepping on live circuits.

Prevention of Slips, Trips, and Falls

Slips and falls are among the most common workplace accidents.

Safety boots address this with outsoles made from durable, high-traction materials like rubber. The tread patterns are specifically engineered to grip slick, oily, or uneven surfaces, providing stable footing.

Defense Against Extreme Environments

Work doesn't stop for bad weather. Safety boots often incorporate features for environmental protection.

This includes water-resistant or waterproof materials to keep feet dry in wet conditions and insulation to keep feet warm in extreme cold.

Understanding the Trade-offs of Steel

While steel offers exceptional protection, it comes with inherent properties that create specific trade-offs. Choosing the right boot means understanding these limitations.

The Issue of Weight

Steel is dense and heavy. This added weight can contribute to fatigue over a long workday, especially for workers who are constantly on their feet.

Conductivity and Interference

Steel readily conducts temperature. This makes steel toe boots less comfortable in extreme cold or heat, as the toe cap can become uncomfortably cold or hot.

Furthermore, the metal will set off metal detectors, which can be an issue in secure facilities. Because it is conductive, a non-EH-rated boot can increase risk in an electrical environment.

The Rise of Composite Alternatives

Modern safety footwear often uses composite materials (like Kevlar, carbon fiber, or plastic) for the toe cap.

Composite toes are much lighter than steel, do not conduct heat or electricity, and won't set off metal detectors. While they meet the same safety standards for impact, steel often provides superior resistance against extreme crushing or cutting forces.

How to Apply This to Your Project

Your specific work environment and daily tasks should dictate your choice.

- If your primary focus is maximum impact and puncture resistance: Steel remains the classic, cost-effective choice for heavy construction, manufacturing, and ironworking.

- If your primary focus is working around electricity or secure areas: An EH-rated composite toe boot is the safer and more convenient option.

- If your primary focus is comfort in extreme temperatures or reducing fatigue: A lightweight composite toe boot will provide better insulation and reduce physical strain over long hours.

Ultimately, selecting the right safety footwear is a critical decision in managing your personal workplace safety.

Summary Table:

| Protection Type | Key Feature | Protects Against |

|---|---|---|

| Impact & Compression | Reinforced Steel Toe Cap | Falling objects, rolling equipment |

| Puncture & Cuts | Steel/Composite Midsole Plate | Nails, screws, sharp debris |

| Electrical Hazards | EH-Rated Non-Conductive Sole | Electric shock from live circuits |

| Slips, Trips & Falls | High-Traction Outsole | Oily, wet, or uneven surfaces |

| Extreme Environments | Waterproofing & Insulation | Wet conditions and extreme cold |

Ready to Equip Your Team with Superior Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, including steel toe and composite toe boots, designed to meet the highest industry standards.

We can help you:

- Source reliable, high-quality safety boots in large quantities.

- Develop custom or private-label footwear tailored to your specific market needs.

- Ensure consistent supply for your projects or retail operations.

Let's discuss your requirements and how we can support your business. Contact our team today for a consultation!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

People Also Ask

- How can calluses be prevented when wearing steel toe boots? A Guide to Lasting Foot Comfort

- Why is a composite toe preferable to a steel toe in winter boots? Superior Insulation & Warmth

- What are the different types of steel toe work boots? Choose the Right Boot for Your Job

- How should you properly break in new steel toe boots? A 3-Phase Guide for Lasting Comfort

- Why do landscapers need steel-toe boots? Essential Protection for a Hazardous Job

- What industries commonly use steel toe boots and why? Essential Protection for High-Risk Work

- What are steel toe work boots and who should wear them? Essential PPE for Hazardous Jobs

- What are steel-toe boots and what is their primary function? Essential Protection for Hazardous Work