At their core, the primary difference is material. Steel toe boots use heavy-duty steel for maximum impact protection, while composite toe boots use non-metallic materials like Kevlar, carbon fiber, or plastic to provide certified protection in a lighter, non-conductive package. Both are designed to meet the same official safety standards, but their material differences create distinct advantages depending on your work environment.

The choice between steel and composite toe boots is not about which is "better" overall, but which is the correct specialized tool for your specific job's risks, environmental conditions, and comfort requirements.

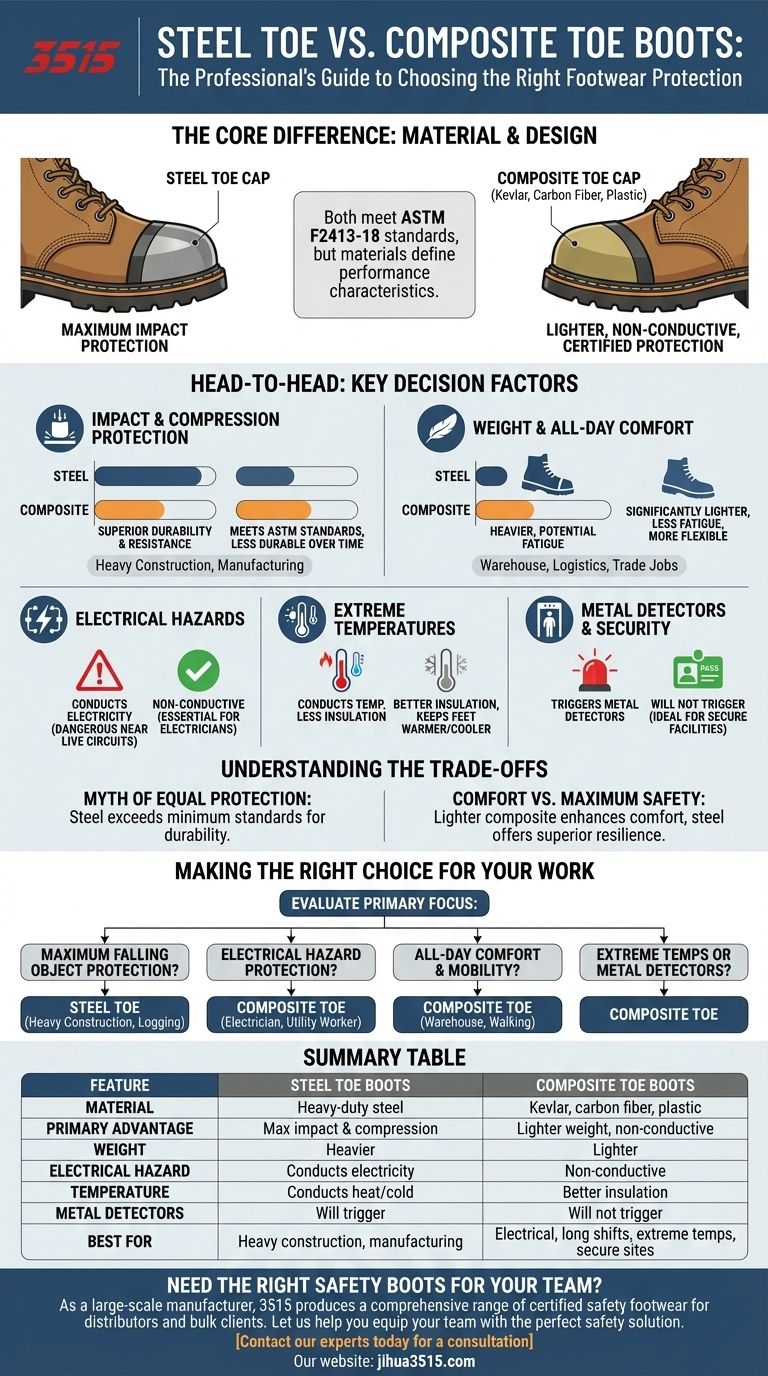

The Core Difference: Material and Design

The protective cap in a safety boot is what defines its category. The material used for this cap dictates nearly all of its performance characteristics.

What is a Steel Toe?

A steel toe cap is the traditional standard for safety footwear. It is a piece of heavy-duty steel shaped to cover the toe area.

This design makes it exceptionally strong against impacts and compression, which is why it has been trusted for decades in the most demanding industrial environments.

What is a Composite Toe?

A composite toe cap is made from a blend of non-metallic materials. These can include Kevlar, carbon fiber, fiberglass, and durable plastics.

The goal of this design is to meet required safety standards without the weight and conductivity of metal, offering a modern alternative for specific job functions.

Head-to-Head: Key Decision Factors

When choosing between steel and composite, your decision should be based on a clear-eyed assessment of your daily tasks and potential hazards.

Impact & Compression Protection

Steel offers the highest level of protection against crushing and impact forces. In environments with a high risk of falling heavy objects, like heavy construction or manufacturing, steel is superior.

While composite toes meet the same ASTM F2413-18 safety standards for a single, specific impact, steel is generally more durable and can better withstand repeated impacts over time.

Weight & All-Day Comfort

Composite toe boots are significantly lighter than their steel counterparts.

This reduction in weight leads to less fatigue over a long workday, making composite the clear winner for anyone who walks or stands for extended periods. They also tend to be more flexible.

Electrical Hazards

This is a critical, non-negotiable distinction. Steel conducts electricity, making steel toe boots a dangerous choice for electricians or anyone working near live circuits.

Composite materials do not conduct electricity, making them the essential choice for anyone facing electrical hazards.

Extreme Temperatures

Metal is an excellent conductor of temperature. In very cold environments, steel toe caps can become extremely cold, drawing heat away from your feet.

Composite materials provide better insulation, helping to keep your feet warmer in the cold and cooler in the heat.

Metal Detectors & Security

Because they contain no metal, composite toe boots will not trigger metal detectors.

This makes them the ideal choice for workers in airports, nuclear power plants, or other secure facilities that require frequent screening.

Understanding the Trade-offs

Choosing the right boot means understanding what you gain and what you give up with each option. There is no single perfect choice for every situation.

The Myth of "Equal Protection"

While both boot types can carry the same ASTM safety rating, this rating only certifies protection against a specific, tested level of impact and compression. Steel's inherent strength gives it an advantage in durability and resistance to forces that exceed the minimum standard.

Comfort vs. Maximum Safety

The central trade-off is often comfort versus absolute strength. Opting for a lighter composite boot enhances all-day comfort and reduces fatigue but sacrifices the superior resilience that steel provides against extreme or repeated impacts.

Making the Right Choice for Your Work

Evaluate your daily environment and prioritize the most critical safety feature for your role.

- If your primary focus is maximum protection against falling objects (e.g., heavy construction, logging, industrial manufacturing): Steel toe boots provide the superior impact and compression resistance you need.

- If your primary focus is electrical hazard protection (e.g., electrician, utility worker): Composite toe boots are the only safe and appropriate choice.

- If your primary focus is all-day comfort and mobility (e.g., warehouse work, logistics, trade jobs with lots of walking): The lighter weight of composite toe boots will significantly reduce fatigue.

- If you work in extreme temperatures or pass through metal detectors: Composite toe boots offer clear advantages in insulation and convenience.

Ultimately, selecting the right safety boot is a critical decision based on a clear understanding of your specific workplace hazards.

Summary Table:

| Feature | Steel Toe Boots | Composite Toe Boots |

|---|---|---|

| Material | Heavy-duty steel | Kevlar, carbon fiber, plastic |

| Primary Advantage | Maximum impact & compression protection | Lighter weight, non-conductive |

| Weight | Heavier | Lighter, less fatigue |

| Electrical Hazard | Conducts electricity (Not for electricians) | Non-conductive (Essential for electricians) |

| Temperature | Conducts heat/cold | Better insulation |

| Metal Detectors | Will trigger | Will not trigger |

| Best For | Heavy construction, industrial manufacturing | Electrical work, long shifts, extreme temperatures, secure sites |

Need the Right Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We can manufacture the exact composite or steel toe boots your workforce needs, ensuring maximum protection and all-day comfort tailored to your specific industry hazards.

Let us help you equip your team with the perfect safety solution.

Contact our experts today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the potential consequences of not wearing steel toe shoes? Avoid Severe Injuries & Financial Losses

- What are the advantages of steel toe caps? Unmatched Impact & Puncture Protection

- What impact do steel toe caps have on toe skin health? Prevent Friction and Pressure in Your Safety Shoes

- What home remedies can help relieve sore feet from steel toe boots? Soothe Aches & Prevent Pain

- Are composite toe boots as durable as steel toe boots? Find the Right Safety for Your Job

- What factors should be considered when choosing between steel and composite toe caps? Ensure Maximum Safety and Comfort

- What are the key features of steel toe footwear? Maximum Impact Protection for Demanding Work

- What are the advantages of composite toe boots over steel toe boots? Lighter, Safer, and More Comfortable