While high-grade rubber is a benchmark for slip resistance, the primary alternatives are Polyurethane (PU), Ethylene Vinyl Acetate (EVA), and Thermoplastic Rubber (TPR). These synthetic compounds are chosen for specific properties like lighter weight, superior shock absorption, or enhanced chemical resistance, making them better suited for certain environments than rubber.

The most effective slip-resistant sole is not determined by a single "best" material. Instead, it's about matching the specific properties of a material—like flexibility, durability, and weight—to the unique demands of the environment where it will be used.

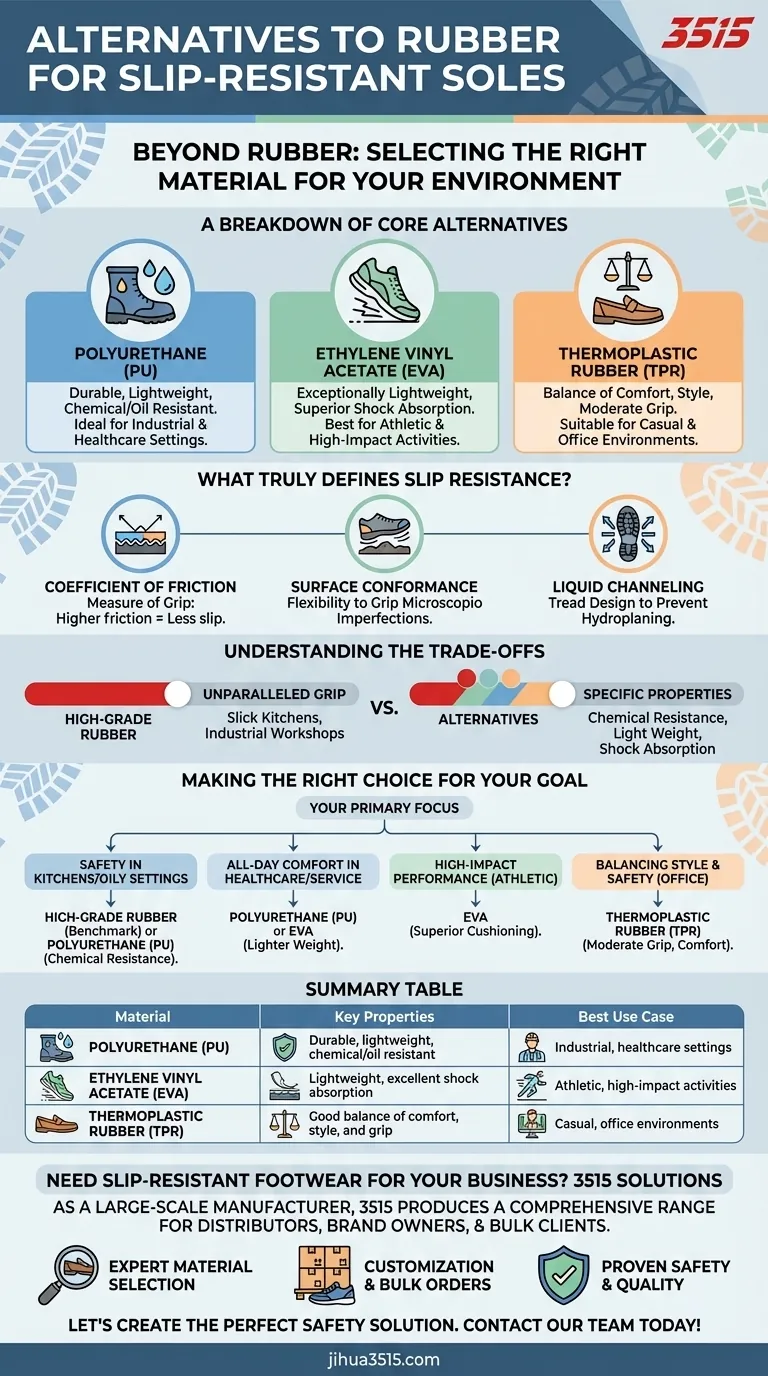

A Breakdown of the Core Alternatives

While often grouped together, each alternative to rubber offers a distinct set of characteristics. Understanding these differences is the key to selecting the appropriate footwear.

Polyurethane (PU)

Polyurethane is a highly versatile polymer known for its durability and light weight. It offers a strong balance of toughness and flexibility.

Critically, PU soles are resistant to chemicals, oils, and abrasion, making them a common choice for industrial and healthcare settings where spills are a concern.

Ethylene Vinyl Acetate (EVA)

EVA is a foam-like material prized for being exceptionally lightweight and providing excellent shock absorption. This makes it a primary material for athletic shoes and footwear designed for high-impact activities.

While it provides cushioning, its durability and grip on oily surfaces may not match that of high-grade rubber or PU.

Thermoplastic Rubber (TPR)

TPR is a synthetic material that mimics many of the properties of rubber but is processed like a plastic. This makes it easier to mold and shape.

It serves as a middle ground, offering a good balance of comfort, style, and moderate slip resistance for less demanding casual or office environments.

What Truly Defines Slip Resistance?

The material itself is only one part of the equation. Three factors work together to prevent slips and falls. A failure in any one of these areas will compromise safety, regardless of the material used.

The Coefficient of Friction

This is the fundamental measure of "grip." A higher coefficient means more force is required to cause a slip. High-grade rubber is known for its exceptional grip, especially on greasy or wet surfaces.

Surface Conformance

A sole must be flexible enough to conform to the microscopic imperfections of a floor. This ability to make maximum contact with the ground is critical for establishing a secure grip.

Liquid Channeling

Effective slip resistance requires a tread pattern designed to channel water, oil, and other liquids away from the bottom of the sole. Without effective channeling, a layer of liquid can cause hydroplaning, eliminating contact between the sole and the floor.

Understanding the Trade-offs

Choosing a material is always an exercise in balancing competing priorities. While rubber is a gold standard for grip, it isn't the optimal choice for every situation.

Why Rubber Remains a Standard

The primary advantage of high-grade rubber is its unparalleled grip and strong traction, particularly on slick, greasy surfaces found in professional kitchens or industrial workshops. Its durability and flexibility make it a reliable and proven choice for high-risk environments.

Where Alternatives Excel

Alternatives shine when other factors are more important than raw grip. PU is superior in environments with chemical exposure. EVA is the clear winner for activities requiring minimal weight and maximum shock absorption. TPR provides a cost-effective balance for everyday, low-risk use.

Making the Right Choice for Your Goal

Your specific environment dictates the ideal material. Use the following guidelines to make an informed decision.

- If your primary focus is safety in kitchens or oily industrial settings: High-grade rubber remains the benchmark, but consider Polyurethane (PU) if chemical and abrasion resistance are equally critical.

- If your primary focus is all-day comfort and reduced fatigue in healthcare or service industries: Polyurethane (PU) and EVA are excellent choices due to their significantly lighter weight.

- If your primary focus is high-impact performance for athletic or recreational use: EVA is the unequivocal choice for its superior cushioning and shock-absorbing properties.

- If your primary focus is balancing style and safety for casual or office wear: Thermoplastic Rubber (TPR) offers a suitable compromise of moderate grip, comfort, and design flexibility.

Ultimately, the safest and most effective sole is one where the material's inherent strengths are precisely aligned with the challenges of your environment.

Summary Table:

| Material | Key Properties | Best Use Case |

|---|---|---|

| Polyurethane (PU) | Durable, lightweight, chemical/oil resistant | Industrial, healthcare settings |

| Ethylene Vinyl Acetate (EVA) | Lightweight, excellent shock absorption | Athletic, high-impact activities |

| Thermoplastic Rubber (TPR) | Good balance of comfort, style, and grip | Casual, office environments |

Need Slip-Resistant Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, ensuring you get the perfect match of material and tread design for your specific environment.

We provide:

- Expert Material Selection: Leverage our expertise to choose between high-grade rubber, PU, EVA, or TPR for optimal performance.

- Customization & Bulk Orders: Tailor footwear to your exact specifications, from tread patterns to branding.

- Proven Safety & Quality: Ensure the highest standards of slip resistance and durability for your workforce.

Let's create the perfect safety solution for your needs. Contact our team today for a consultation!

Visual Guide

Related Products

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

People Also Ask

- What are the key considerations for finding a perfect fitting safety toe boot? Avoid Injury and Discomfort

- Are safety shoes worth it? The Critical Investment in Workplace Safety & Foot Health

- What are some examples of footwear requirements in different work settings? Ensure Safety and Compliance

- What is the most common shoe width for safety toe boots? The Critical Fit Guide for Comfort & Safety

- Why is proper fit crucial for safety toe boots? Avoid These Hidden Hazards