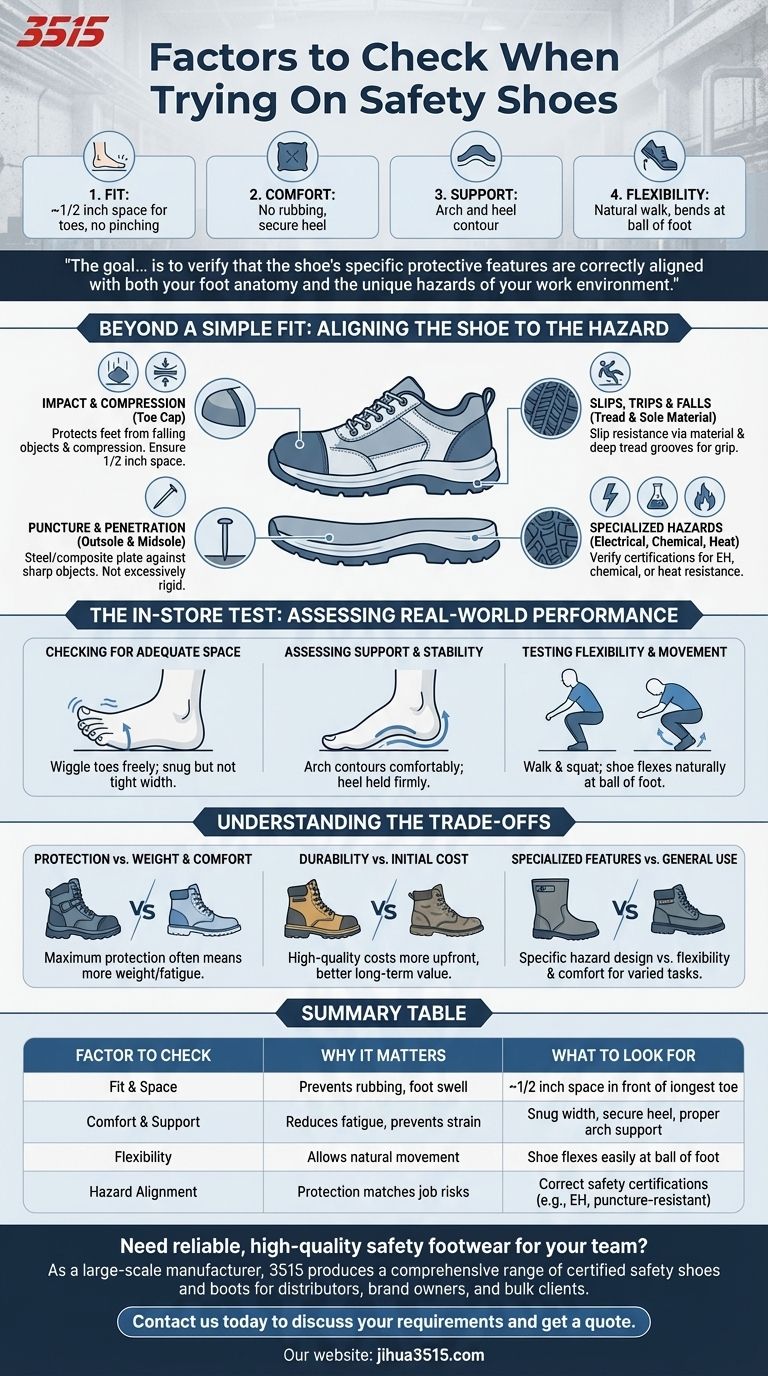

When trying on safety shoes, you must check four immediate factors: the fit, the comfort, the support, and the flexibility. Ensure there is adequate room for your toes, that the shoe doesn't pinch or rub anywhere, that your arch and heel feel secure, and that you can walk and bend your foot naturally without excessive stiffness.

The goal of trying on a safety shoe is not just to find a comfortable fit, but to verify that the shoe's specific protective features are correctly aligned with both your foot anatomy and the unique hazards of your work environment.

Beyond a Simple Fit: Aligning the Shoe to the Hazard

A safety shoe is a piece of specialized equipment. Its effectiveness depends entirely on how its features map to the risks you face daily. Understanding this connection is the most critical step in the selection process.

Impact and Compression (The Toe Cap)

The most recognized feature of a safety shoe is the reinforced toe cap. Its purpose is to protect your feet from falling objects and compression. When trying the shoe on, ensure there is about a half-inch of space between your longest toe and the end of the cap to prevent rubbing and allow for natural foot swell.

Puncture and Penetration (The Outsole & Midsole)

If you work around nails, scrap metal, or other sharp objects, a puncture-resistant sole is non-negotiable. This is often a steel or composite plate integrated into the midsole. The shoe should not feel excessively rigid, but you should have confidence in the sole's substantial construction.

Slips, Trips, and Falls (The Tread & Sole Material)

Slip resistance is a function of the outsole's material and its tread pattern. For wet or oily surfaces, soles made of soft rubber often provide the best grip. Examine the tread—deep, well-defined grooves are designed to channel liquids away from the point of contact, increasing traction.

Specialized Hazards (Electrical, Chemical, and Heat)

Some jobs require protection beyond the basics. Electrical Hazard (EH) rated shoes are built with non-conductive materials. Others use special materials to resist chemical spills or extreme heat. Always verify that the shoe's safety certification explicitly matches these specific environmental risks.

The In-Store Test: Assessing Real-World Performance

Once you've matched the shoe's technical specifications to your job's hazards, you must perform a physical check to ensure it will work for your body over a long shift.

Checking for Adequate Space

Your feet can swell throughout the workday. A proper fit accounts for this. You should be able to wiggle all your toes freely inside the toe cap. The width should be snug but not tight, preventing your foot from sliding side-to-side.

Assessing Support and Stability

A good safety shoe should feel like an extension of your foot. Pay close attention to the arch support—it should contour comfortably to your foot's natural shape. The heel should be firmly cupped, preventing any lifting or slipping as you walk.

Testing Flexibility and Movement

Walk around in the shoes for several minutes. Squat down and bend your feet. The shoe should flex at the ball of your foot naturally. Excessive stiffness can lead to fatigue and an unnatural gait, increasing the risk of other injuries.

Understanding the Trade-offs

Choosing the right safety shoe is always an exercise in balancing competing factors. Being aware of these trade-offs allows you to make an informed decision rather than a compromised one.

Protection vs. Weight and Comfort

Maximum protection often means more weight. A heavy-duty steel toe and puncture plate will offer superior defense but can lead to greater fatigue over a 10-hour shift compared to a lighter composite-toe model.

Durability vs. Initial Cost

High-quality materials and construction cost more upfront but provide better long-term value and more reliable protection. Cheaper options may meet minimum safety standards but can wear out quickly, compromising safety and costing more over time.

Specialized Features vs. General Use

A shoe designed for a specific hazard, like a foundry boot, offers excellent heat resistance but may be heavy and lack the flexibility needed for a job that requires constant walking and climbing.

Making the Right Choice for Your Work Environment

Your specific job function is the ultimate guide. Use these principles to narrow your focus.

- If your primary focus is construction or heavy industry: Prioritize a certified safety toe (steel or composite) and a puncture-resistant sole.

- If your primary focus is food service or wet environments: Make slip resistance, specifically tread pattern and sole material, your number one criterion.

- If your primary focus is electrical work: Ensure the shoe carries an explicit Electrical Hazard (EH) rating.

- If your primary focus is warehousing or logistics: Seek a balance between a lighter composite toe, good arch support, and flexibility for all-day comfort.

Ultimately, investing in the right safety footwear is a direct investment in your own daily health and well-being.

Summary Table:

| Factor to Check | Why It Matters | What to Look For |

|---|---|---|

| Fit & Space | Prevents rubbing and accommodates foot swell. | ~1/2 inch of space in front of longest toe. |

| Comfort & Support | Reduces fatigue and prevents strain. | Snug width, secure heel, and proper arch support. |

| Flexibility | Allows natural movement and gait. | Shoe flexes easily at the ball of the foot. |

| Hazard Alignment | Ensures protection matches job risks. | Correct safety certifications (e.g., EH, puncture-resistant). |

Need reliable, high-quality safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring the perfect balance of comfort, durability, and job-specific safety features.

Contact us today to discuss your requirements and get a quote tailored to your needs.

Visual Guide

Related Products

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What core features are required in high-performance safety shoes? Gear for Extreme Heat & Complex Environments

- What role do industrial safety shoes play in improving the labor environment? Boost Safety and Reduce Worker Stress

- What role do slip-resistant safety shoes play in high-risk environments? Essential Protection for Industrial Safety

- How are gait analysis research findings applied to the functional design of safety shoes and tactical boots?

- What should you consider when choosing work or safety shoes? A Guide to Finding the Perfect Fit for Your Job

- What are the common codes for security guard safety boots? Decode Your Protection

- Why Random Forest over Deep Learning for Occupational Health Footwear Models? Balancing Accuracy and Interpretability

- Why is a professional foot protection solution essential for the hygiene lock process in poultry farming? Secure Your Flock