To properly try on work boots, physiotherapists advise you to wear your typical work socks, try on both boots, and actively test them by walking, squatting, and mimicking your daily work movements. The goal is to assess not just size, but how the boot moves with your foot.

The most common mistake is focusing only on length and toe room. A truly supportive work boot must align with your foot's natural mechanics, particularly at the flex point and the width, to prevent long-term joint pain and muscle fatigue.

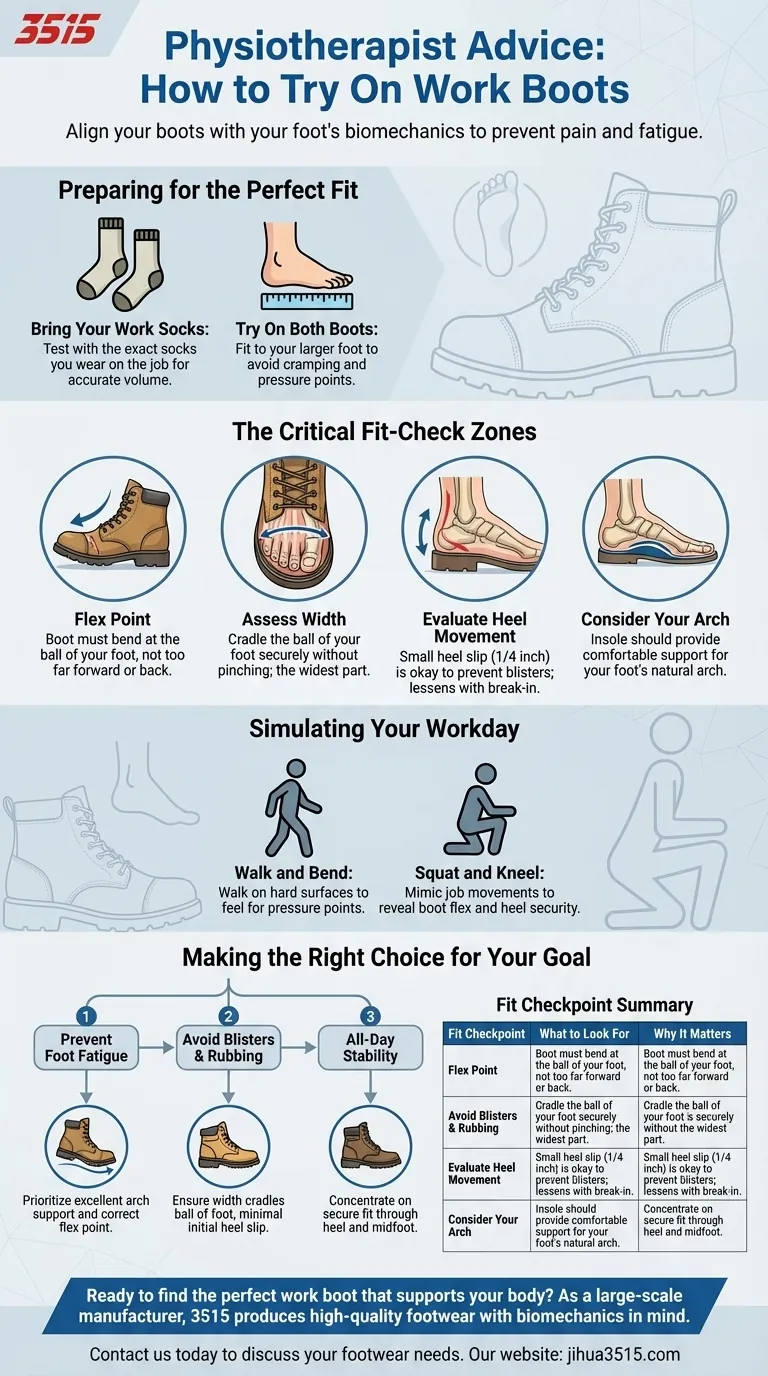

Preparing for the Perfect Fit

Before you even put on a boot, a few simple steps can dramatically improve your chances of finding the right pair. This is about creating a realistic testing environment.

Bring Your Work Socks

The thickness of your socks significantly alters how a boot fits. Always test boots with the exact type of socks you wear on the job to get an accurate feel for the volume and cushioning.

Try On Both Boots

Nearly everyone has one foot that is slightly larger than the other. You must fit the boot to your larger foot to avoid cramping and pressure points.

The Critical Fit-Check Zones

Once the boots are on, your focus should shift from simple comfort to specific biomechanical checkpoints. This is where you can identify a boot that supports versus one that hinders your movement.

Check the Flex Point

The boot must bend where your foot naturally bends—at the ball of your foot. If the boot's flex point is too far forward or back, it will force your foot to work against the boot's structure with every step, leading to fatigue and strain.

Assess the Width, Not Just the Length

The boot should cradle the ball of your foot securely without pinching. This is the widest part of your foot and a critical area for support. Too much pressure here can lead to nerve pain and circulation issues.

Evaluate Heel Movement

A small amount of heel slip (about a quarter-inch) is often acceptable, especially in new, stiff leather boots. This minor movement prevents blisters caused by a heel cup that is too tight. The slip should lessen as the boot breaks in.

Consider Your Arch

The insole of the boot should provide comfortable support for your foot's natural arch. Proper arch support is vital for distributing pressure evenly across your foot and preventing conditions like plantar fasciitis.

Simulating Your Workday

A boot can feel fine when you're standing still, but the real test is how it performs when you move. The final step is to put the boots through their paces right there in the store.

Walk and Bend

Walk around the store, preferably on a hard surface, to feel for any rubbing or pressure points.

Squat and Kneel

Perform movements that mimic your job, like squatting, kneeling, or climbing stairs if possible. This will reveal how the boot flexes and if your heel is secure or slipping excessively.

Making the Right Choice for Your Goal

Use these final checkpoints to select the best boot based on your primary need.

- If your primary focus is preventing foot fatigue: Prioritize a boot with excellent arch support and a flex point that perfectly matches your foot's natural bend.

- If your primary focus is avoiding blisters and rubbing: Ensure the width cradles the ball of your foot without pinching and that there is only minimal, not excessive, initial heel slip.

- If your primary focus is all-day stability: Concentrate on a secure fit through the heel and midfoot to lock your foot in place, even if the toe box feels a bit roomy.

Investing a few extra minutes in the fitting process is the most effective way to protect your body for years on the job.

Summary Table:

| Fit Checkpoint | What to Look For | Why It Matters |

|---|---|---|

| Flex Point | Boot bends at the ball of your foot. | Prevents muscle strain and fatigue. |

| Width | Ball of foot is cradled securely without pinching. | Avoids nerve pain and circulation issues. |

| Heel Movement | A quarter-inch of slip is acceptable. | Prevents blisters; should lessen as boot breaks in. |

| Arch Support | Insole supports your foot's natural arch. | Distributes pressure, prevents plantar fasciitis. |

Ready to find the perfect work boot that supports your body?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear designed with biomechanics in mind. We provide durable and comfortable work boots, shoes, and boots for distributors, brand owners, and bulk clients, ensuring a perfect fit for every worker.

Contact us today to discuss your footwear needs and discover how our production capabilities can support your business and your workforce's well-being.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do some boots combine materials for better performance? Achieve Superior Safety & Comfort

- What does CE-approval indicate for safety boots? Your Guide to EU-Compliant Footwear Protection

- What are the OSHA recommendations for wearing protective footwear? A Legal Guide to Workplace Foot Safety

- What are the advantages of rubber soles for work boots? Unbeatable Grip & Durability

- What were some early hazards that safety footwear addressed? A Guide to Essential Foot Protection