Okay, so the user wants the lowdown on OSHA's footwear recommendations, but let's be clear: this isn't just a suggestion; it's a requirement. OSHA mandates that employers ensure employees wear protective footwear in any work area where there's a risk of foot injury. This covers everything from falling objects to electrical hazards. My goal is to break this down in a way that's useful, actionable, and helps the user understand their legal obligations.

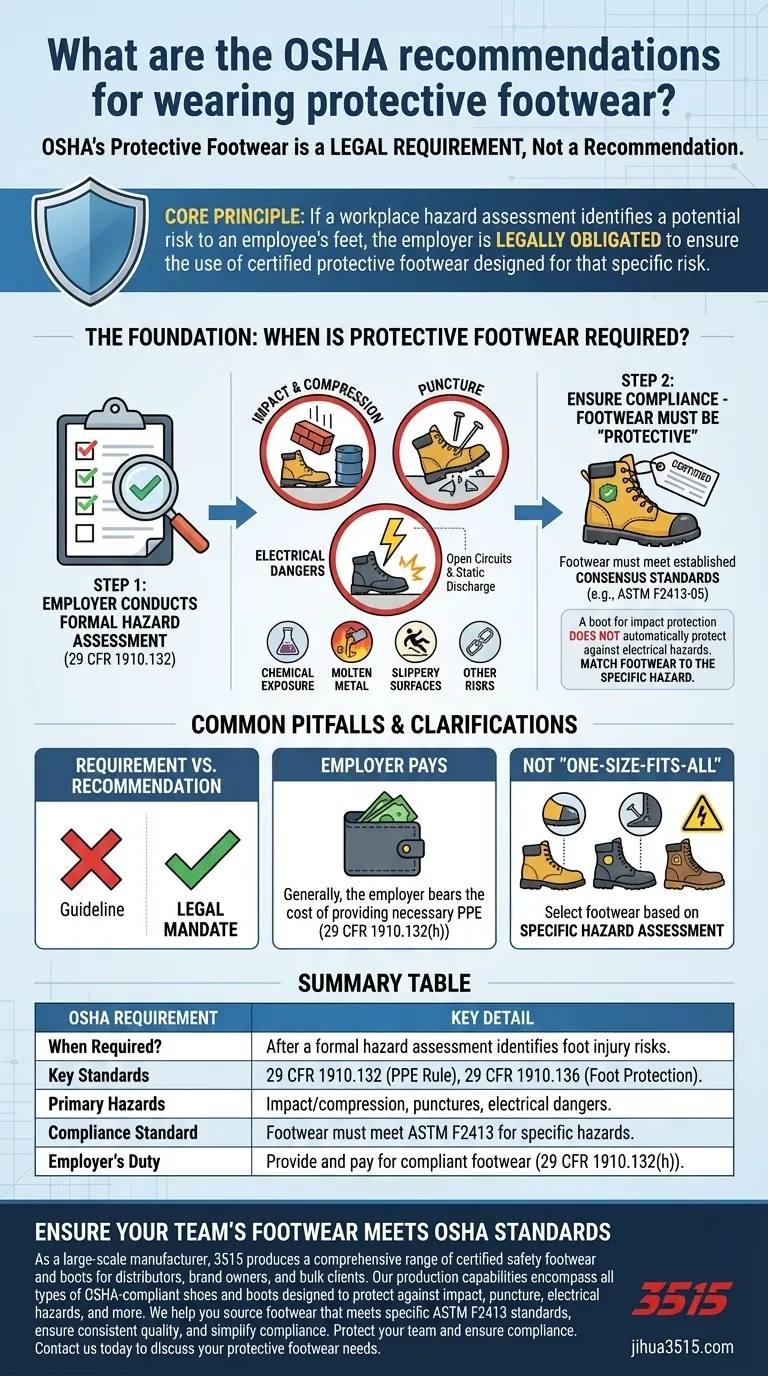

Key Takeaway: If a workplace hazard assessment identifies a potential for foot injury, the employer is legally obligated to ensure the use of certified protective footwear designed to mitigate that specific risk. This isn't optional; it's the law.

Now, let's get into the specifics, because OSHA doesn't just throw out random rules.

The Foundation: When Is Protective Footwear Required?

First, the requirement isn't based on job title, but on a formal hazard assessment of the work environment (29 CFR 1910.132). This is critical. The employer must perform this assessment. It's not a "maybe," it's a "must." From my perspective, these assessments usually uncover three primary hazard categories.

- Impact & Compression: Think falling or rolling objects.

- Puncture: Sharp objects that could pierce the sole.

- Electrical Dangers: Static discharge or the risk of electric shock.

Beyond these, there are other environmental risks, such as:

- Chemical & Material Exposure: Corrosive or poisonous materials, molten metal splashes.

- Surface Conditions: Hot or slippery surfaces.

Ensuring Compliance: What Makes Footwear "Protective"?

OSHA doesn't design the boots themselves. Instead, they require the footwear to meet established safety standards. So how do you know if footwear is actually "protective"?

The crucial piece here is that the footwear must be tested and classified according to recognized consensus standards. One standard specifically mentioned in these references is the ASTM F2413-05. This standard provides a framework for testing and classifying footwear against specific hazards (e.g., impact, puncture, electrical). It's up to the employer to ensure that the footwear meets the appropriate standard for the identified hazards.

Common Pitfalls and Clarifications

- "Recommendation" vs. "Requirement": Let me reiterate - it's a requirement. This is a legal mandate.

- Who Pays? Generally, the employer bears the cost of providing personal protective equipment. The references do cite 29 CFR 1910.132(h)(2) which outlines who's responsible for the expense.

- Not a "One-Size-Fits-All" Solution: A steel-toe boot for impact protection doesn't automatically protect against electrical hazards. The footwear must match the specific hazard.

How to Apply This to Your Workplace

This isn't just theoretical; it's about practical, actionable steps based on your specific role and workplace.

- If you are an employer: Your primary responsibility is to conduct a thorough foot hazard assessment for every work area and role.

- If you are a safety manager: Document your hazard assessment and ensure all protective footwear meets the specific ASTM standards required for the identified risks.

- If you are an employee: Use the provided protective footwear as required and report any damage or wear that could compromise its effectiveness.

Proactively identifying and mitigating foot hazards is not just about compliance; it is a fundamental pillar of a safe and responsible workplace. To be clear, OSHA's guidance on protective footwear is a legal requirement, not a simple recommendation. The Occupational Safety and Health Administration (OSHA) mandates that employers must ensure their employees use protective footwear whenever they work in areas with a present danger of foot injury. These dangers include, but are not limited to, injuries from falling or rolling objects, punctures from sharp items, and exposure to electrical hazards.

The core principle of OSHA's rule is straightforward: if a workplace hazard assessment identifies a potential risk to an employee's feet, the employer is legally obligated to ensure the use of certified protective footwear specifically designed to mitigate that risk.

The Foundation: When Is Protective Footwear Required?

The need for protective footwear is not determined by job title but by a formal assessment of the work environment. OSHA places the responsibility squarely on the employer to identify and address potential dangers.

The Hazard Assessment Rule

Under standard 29 CFR 1910.132, employers must conduct a thorough hazard assessment of their workplace. This process is the trigger for all Personal Protective Equipment (PPE) requirements, including foot protection.

If this assessment reveals a risk of foot injury, the employer must select and require employees to use appropriate footwear.

Three Primary Hazard Categories

OSHA's standard (29 CFR 1910.136) specifically calls out three major categories of foot injuries that mandate protection.

- Impact and Compression: This covers dangers from falling or rolling objects, such as tools, materials, or heavy equipment.

- Puncture: This involves risks from sharp objects that could pierce the sole of a shoe, like nails, scrap metal, or glass.

- Electrical Dangers: This includes protection against open circuits (electric shock) and the mitigation of static electricity buildup.

Other Environmental Risks

Beyond the primary categories, the hazard assessment should also identify other workplace-specific dangers.

These can include exposure to molten metal splashes, corrosive or poisonous materials, and working on excessively hot or slippery surfaces. Each of these conditions may require a specific type of protective footwear.

Ensuring Compliance: What Makes Footwear "Protective"?

OSHA does not design or manufacture safety footwear. Instead, it requires that the footwear used in the workplace meets established, independent consensus standards to be considered compliant.

The Role of Consensus Standards

To be considered "protective" under OSHA regulations, footwear must meet specific performance criteria outlined by organizations like the American Society for Testing and Materials (ASTM).

The ASTM F2413 Standard

The key standard referenced is ASTM F2413. This standard establishes the minimum requirements for the design, performance, testing, and classification of protective footwear.

A boot that is ASTM F2413-compliant will be clearly marked with the specific hazards it protects against (e.g., impact, compression, puncture-resistance, electrical hazard).

Employer's Responsibility for Verification

It is the employer's duty to not only identify the need for protective footwear but also to ensure the chosen footwear carries the correct ASTM rating for the specific hazards present in their workplace.

Common Pitfalls and Clarifications

Misunderstanding the nuances of OSHA's requirements can lead to non-compliance and, more importantly, workplace injuries. It's crucial to be precise in your understanding.

"Requirement" vs. "Recommendation"

The most common mistake is viewing this as a guideline. OSHA standards are law. Failure to assess hazards and provide appropriate PPE can result in significant penalties.

It's Not a "One-Size-Fits-All" Solution

A steel-toed boot designed for impact protection offers no defense against electrical shock unless it is specifically rated for that purpose.

The footwear must be selected to match the specific hazard. A single job may even require footwear with multiple protective classifications.

Employer's Obligation to Provide

OSHA's regulations (29 CFR 1910.132(h)) generally require employers to pay for and provide their employees with the necessary PPE, including protective footwear.

Making the Right Choice for Your Goal

To ensure compliance and safety, your approach should be guided by your role and the specific risks identified in your work environment.

- If you are an employer: Your primary responsibility is to conduct and document a thorough foot hazard assessment for every work area and role.

- If you are a safety manager: You must select footwear that meets the specific ASTM standards required for the identified risks and ensure employees are trained on its proper use.

- If you are an employee: You are required to wear the provided protective footwear as instructed and are responsible for reporting any damage that could compromise its effectiveness.

Proactively identifying and mitigating foot hazards is not just about compliance; it is a fundamental pillar of a safe and responsible workplace.

Summary Table:

| OSHA Requirement | Key Detail |

|---|---|

| When Required? | After a formal hazard assessment identifies foot injury risks. |

| Key Standards | 29 CFR 1910.132 (PPE Rule), 29 CFR 1910.136 (Foot Protection). |

| Primary Hazards | Impact/compression, punctures, electrical dangers. |

| Compliance Standard | Footwear must meet ASTM F2413 for specific hazards. |

| Employer's Duty | Provide and pay for compliant footwear (29 CFR 1910.132(h)). |

Ensure Your Team's Footwear Meets OSHA Standards

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of OSHA-compliant shoes and boots designed to protect against impact, puncture, electrical hazards, and more.

We help you:

- Source footwear that meets specific ASTM F2413 standards for your hazard assessment.

- Ensure consistent quality and reliable protection for your workforce.

- Simplify compliance with a trusted manufacturing partner.

Protect your team and ensure compliance. Contact us today to discuss your protective footwear needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- How do SCR and HRV sensors assess safety shoe comfort? Quantifying Ergonomic Stress and Fatigue

- Why must enterprises maintain a stable supply of personal protective equipment like Safety Shoes? Ensure Worker Safety

- What are the functions of the insole in safety shoes? Essential for Stability, Comfort & Protection

- How does management wearing safety shoes impact safety systems? Leading by Example to Drive Cultural Compliance

- What is the significance of industrial sewing machines in footwear production? Ensuring Durability and Safety

- What features make oilfield safety shoes resistant to heat and flames? Protect Against Extreme Temperatures

- What are the primary hazards that firefighters' footwear must protect against? Engineered for Multi-Threat Environments

- How does high-retroreflective material improve footwear safety? Enhancing Visibility for Vulnerable Road Users