In the early days of industrial work, safety footwear was developed to address a core set of severe physical dangers. The primary hazards included crushing injuries from heavy falling objects, punctures from sharp instruments on the ground, and chemical burns from spills, particularly in high-risk sectors like mining, manufacturing, and construction. The introduction of the steel-toe boot in the 1930s was the first major innovation designed specifically to combat these immediate threats.

The core purpose of early safety footwear was not comprehensive protection, but a direct and robust response to the most common and debilitating foot injuries of the industrial era: impact, compression, and puncture.

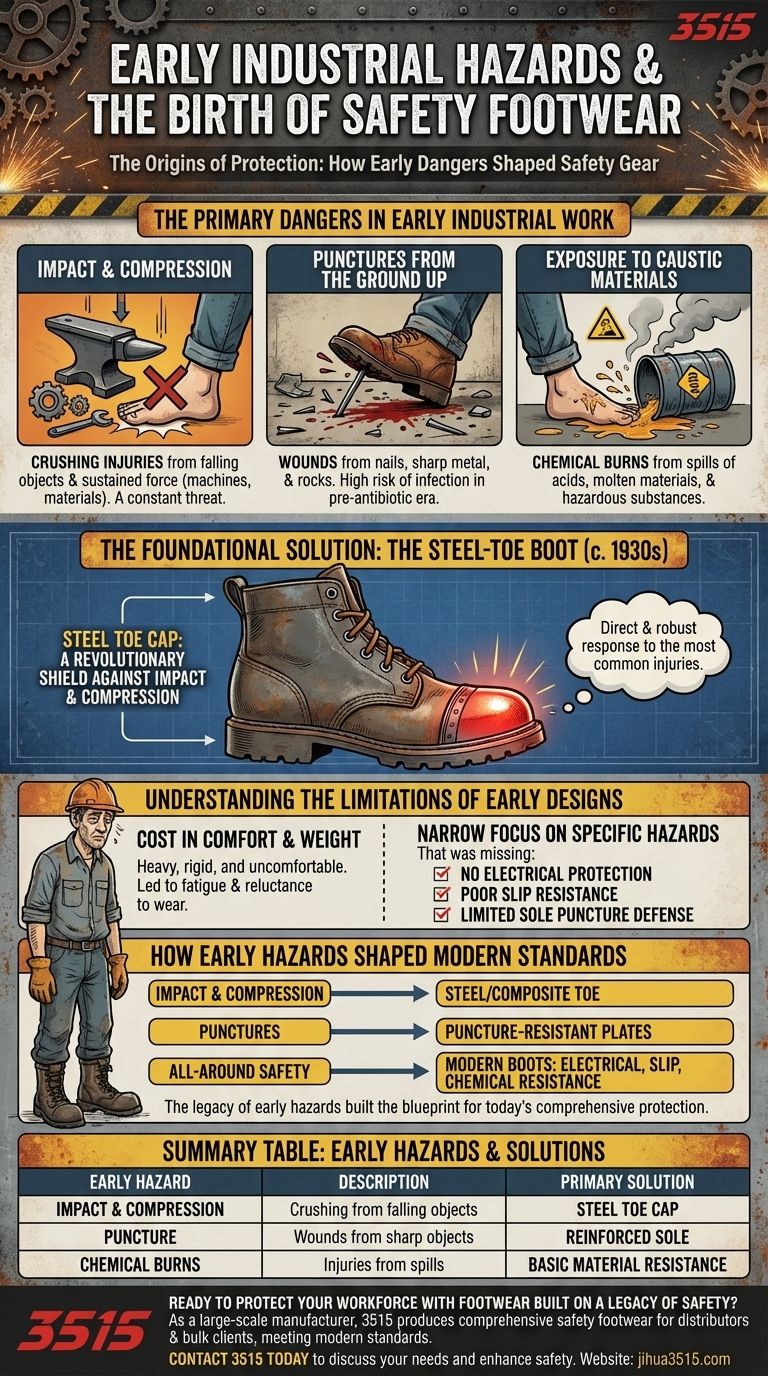

The Primary Dangers in Early Industrial Work

Before standardized Personal Protective Equipment (PPE), a worker's feet were exceptionally vulnerable. The environment was fundamentally different, and common leather or cloth shoes offered virtually no meaningful protection.

The Constant Threat of Impact and Compression

In factories, mines, and construction sites, the movement of heavy materials was a constant. Dropped tools, building materials, or machine parts could easily result in crushed toes and feet.

This risk of impact (a sudden force) and compression (a sustained force) was the most immediate danger that early safety footwear sought to mitigate.

Punctures from the Ground Up

The ground on an industrial site was often littered with hazards. Discarded nails, sharp scrap metal, and jagged rocks posed a significant threat of puncture wounds through the sole of a standard shoe.

These injuries were not only painful but also carried a high risk of severe infection in an era before modern antibiotics were widely available.

Exposure to Caustic and Hazardous Materials

Early industrial processes often involved hazardous chemicals, acids, and molten materials. Spills were common, and without protective footwear, workers were exposed to severe chemical burns and other foot injuries.

The Foundational Solution: The Steel Toe

The response to these dangers was not a complex system but a remarkably simple and effective innovation that became the bedrock of safety footwear.

A Simple Principle for a Major Problem

The steel-toe boot, introduced in the 1930s, was a revolutionary development. By placing a small, reinforced piece of steel in the cap of the boot, it provided a shield against the primary threats of impact and compression.

This single design element drastically reduced the frequency of the most common and serious foot injuries of the time, fundamentally changing worker safety.

Understanding the Limitations of Early Designs

While transformative, the first generations of safety footwear were far from perfect. They were a focused solution with notable trade-offs.

The Cost in Comfort and Weight

Early steel-toe boots were notoriously heavy, rigid, and uncomfortable. This often led to worker fatigue over long shifts and, in some cases, a reluctance to wear the protective gear at all.

A Narrow Focus on Specific Hazards

The initial designs were almost exclusively concerned with protecting the toes from impact. They offered little to no specialized protection against other dangers that are standard today, such as electrical shock, slips, or even advanced puncture resistance in the sole.

How Early Hazards Shaped Modern Standards

The evolution of safety footwear has been a direct response to the lessons learned from these initial challenges. The foundational hazards of the past created the blueprint for the comprehensive protection we expect today.

- If your primary focus is protection from falling objects: Know that the steel toe (or modern composite toe) remains the direct legacy of this original industrial hazard.

- If your primary focus is preventing punctures: Recognize that puncture-resistant plates in the sole were the logical next step after securing the toe box.

- If your primary focus is all-around safety: Appreciate that modern boots build upon this foundation, adding features for electrical, chemical, and slip resistance that were not priorities in early designs.

Understanding the origin of safety footwear clarifies its essential purpose: to provide a critical barrier between you and the inherent risks of your work environment.

Summary Table:

| Early Hazard | Description | Primary Solution |

|---|---|---|

| Impact & Compression | Crushing injuries from heavy falling objects. | Steel Toe Cap |

| Puncture | Wounds from nails, sharp metal, or rocks on the ground. | Reinforced Sole |

| Chemical Burns | Injuries from spills of acids and hazardous materials. | Basic Material Resistance |

Ready to protect your workforce with footwear built on a legacy of safety?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered to meet modern standards while addressing the fundamental hazards of any industrial environment.

Contact 3515 today to discuss your specific needs and discover how our reliable, high-quality footwear can enhance safety and productivity for your team.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What is the function of Inertial Sensors in smart safety shoes? Unlock Real-Time Worker Monitoring and Accident Prevention

- What changes does the new EN ISO 20345 standard introduce regarding the FO marking? It's now optional.

- What factors should be considered when selecting industry-appropriate safety shoes? A Guide to Matching Hazards with Protection

- What materials are alloy toe boots made from? Lightweight Protection for All-Day Comfort

- What are the biomechanical differences between training shoes and professional safety shoes? | Gait Recovery Insights

- What is the ASTM standard for metatarsal protection? Ensuring Your Footwear Meets the 75 ft-lb Impact Test

- What technical standards for compression and puncture resistance must industrial safety shoes meet for railway yards?

- What are the different safety classes under the EN ISO 20345 standard? A Guide to S1, S2, S3, S4, S5