In short, CE marking on safety boots is a manufacturer's declaration that the footwear meets the essential health, safety, and environmental protection standards required by the European Union. This mark signifies that the boots are compliant with the EU's regulations for Personal Protective Equipment (PPE), ensuring they have undergone specific testing to verify their protective features.

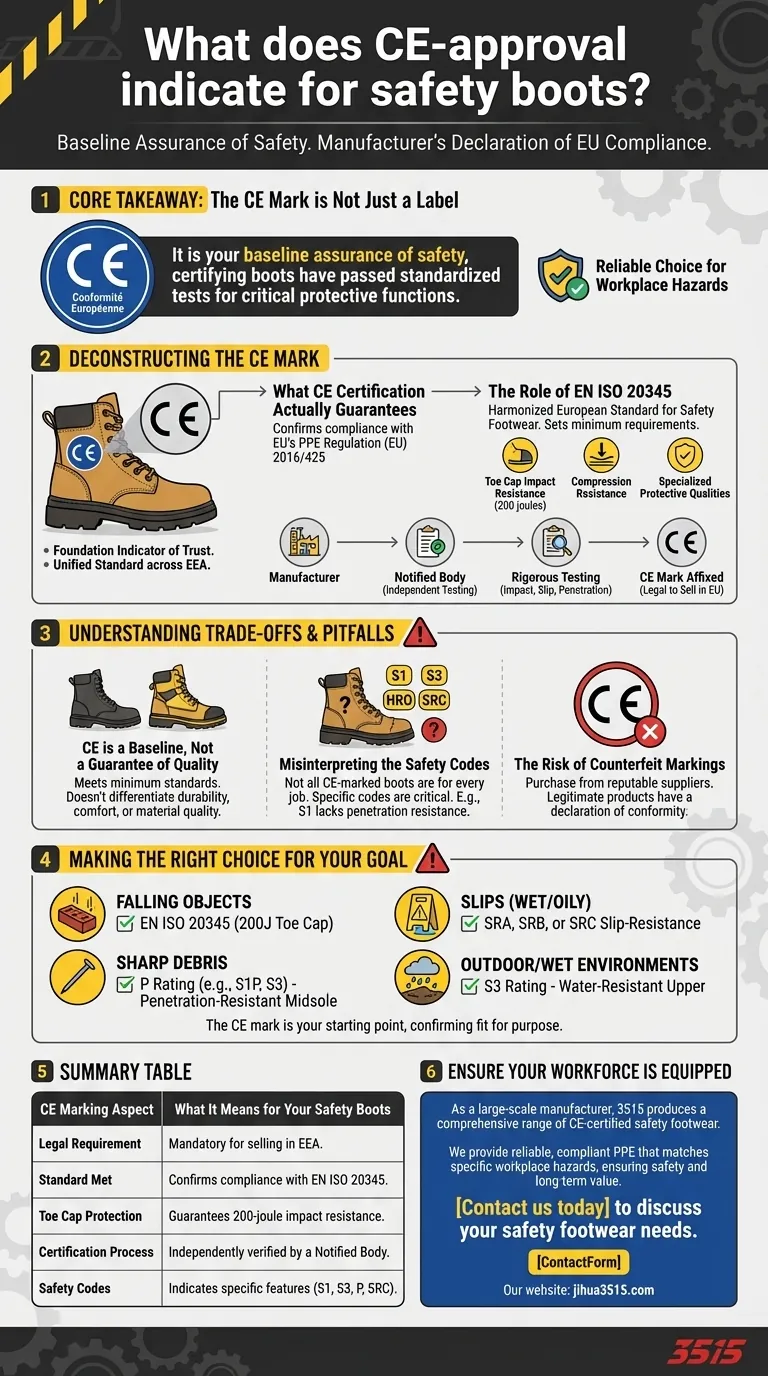

The core takeaway is that the CE mark isn't just a label; it is your baseline assurance of safety. It certifies that the boots have passed standardized tests for critical protective functions, making them a reliable choice for workplace hazards.

Deconstructing the CE Mark

When you select safety footwear, you are trusting it to protect you from serious injury. The CE mark is the foundational indicator of that trust, representing a unified standard across the European Economic Area (EEA).

What CE Certification Actually Guarantees

The "CE" stands for Conformité Européenne, which is French for "European Conformity."

It confirms the product meets the requirements of the EU's PPE Regulation (EU) 2016/425. This means the boots have been tested against a specific standard, most commonly EN ISO 20345.

This standard sets minimum requirements for features like toe cap impact resistance (tested to 200 joules), compression resistance, and other specialized protective qualities.

The Role of EN ISO 20345

This is the harmonized European standard specifically for safety footwear. A boot cannot be CE marked without meeting its requirements.

The standard defines different categories of protection, which are indicated by codes on the boot's label. This allows you to match the boot's capabilities to your specific workplace risks.

The Testing and Certification Process

To gain CE marking, the manufacturer must have the safety boot independently tested and certified by a "Notified Body."

This third-party organization rigorously tests the footwear against the criteria laid out in EN ISO 20345. They assess everything from the strength of the toe cap to the slip resistance of the sole.

Only after passing these tests can the manufacturer legally affix the CE mark and sell the product within the EU market.

Understanding the Trade-offs and Common Pitfalls

While the CE mark is a crucial indicator of safety, relying on it blindly without understanding the details can lead to a false sense of security.

CE is a Baseline, Not a Guarantee of Quality

The CE mark confirms that a boot meets minimum safety standards. It does not differentiate between a basic, compliant boot and a high-performance one.

Two CE-marked boots can have vastly different levels of durability, comfort, and material quality. The mark ensures safety, but not necessarily long-term value or comfort.

Misinterpreting the Safety Codes

A common mistake is assuming any CE-marked boot is suitable for any job. The specific safety codes (e.g., S1, S3, HRO, SRC) are critical.

For example, an S1 boot has a protective toe cap and antistatic properties but lacks penetration resistance. Using it on a construction site with sharp debris would be a critical failure in PPE selection, even though the boot is CE marked.

The Risk of Counterfeit Markings

In rare cases, products may carry fraudulent CE markings. This is why it is essential to purchase safety footwear from reputable suppliers and trusted brands.

A legitimate product will always have a declaration of conformity available, detailing the standards it meets and the Notified Body that certified it.

Making the Right Choice for Your Goal

Selecting the correct CE-marked boot requires matching its certified features to your specific workplace hazards.

- If your primary focus is protection from falling objects: Ensure the boot is certified to EN ISO 20345, which guarantees a 200-joule tested toe cap.

- If your primary focus is working on sites with sharp debris: Look for a boot with a "P" rating (like S1P or S3), which indicates a penetration-resistant midsole.

- If your primary focus is preventing slips in wet or oily conditions: Prioritize boots with an SRA, SRB, or (ideally) SRC slip-resistance rating.

- If your primary focus is outdoor or wet-environment work: Choose a boot with a water-resistant upper, such as the S3 rating, to ensure both safety and comfort.

Ultimately, the CE mark is your starting point for safety, confirming the boot is fit for purpose and has been independently verified.

Summary Table:

| CE Marking Aspect | What It Means for Your Safety Boots |

|---|---|

| Legal Requirement | Mandatory for selling safety footwear in the European Economic Area (EEA). |

| Standard Met | Confirms compliance with the EN ISO 20345 standard for safety footwear. |

| Toe Cap Protection | Guarantees impact resistance tested to 200 joules. |

| Certification Process | Independently verified by a third-party "Notified Body." |

| Safety Codes | Indicates specific protective features (e.g., S1, S3, P, SRC). |

Ensure your workforce is equipped with the right protection.

As a large-scale manufacturer, 3515 produces a comprehensive range of CE-certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, rigorously tested to meet and exceed standards like EN ISO 20345.

We provide reliable, compliant PPE that matches specific workplace hazards, ensuring both safety and long-term value. Contact us today to discuss your safety footwear needs and request a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What is the importance of ASTM International in safety footwear standards? Ensure OSHA Compliance and Worker Safety

- How do professional ergonomic shoes protect against musculoskeletal disorders? Boost foot health and workplace safety.

- What is the current safety footwear standard in Europe? Your Guide to EN ISO 20345

- What do the symbols on safety footwear indicate? A Guide to Decoding Boot Safety Ratings

- What are the benefits of ergonomic safety shoes for older workers? Enhancing Stability and Joint Health for Ages 50-65

- What does the compression rating in safety toe boots mean? Your Guide to C/75 Protection

- What is Goodman and Kruskal’s Gamma for Safety Shoe Analysis? Link Performance Ratings to Wear Frequency

- How is the Functional Reach Test utilized to measure the stability limits of safety shoes? Enhancing Industrial Safety