The primary advantages of rubber soles for work boots are their exceptional durability, superior grip, and high resistance to hazardous materials like oil, water, and chemicals. These qualities make rubber a foundational material for safety and performance in demanding work environments.

Rubber's value in work boots goes beyond a single feature. It delivers a critical combination of grip, resilience, and environmental protection that is difficult to achieve with other sole compounds, making it an engineering choice for uncompromising safety.

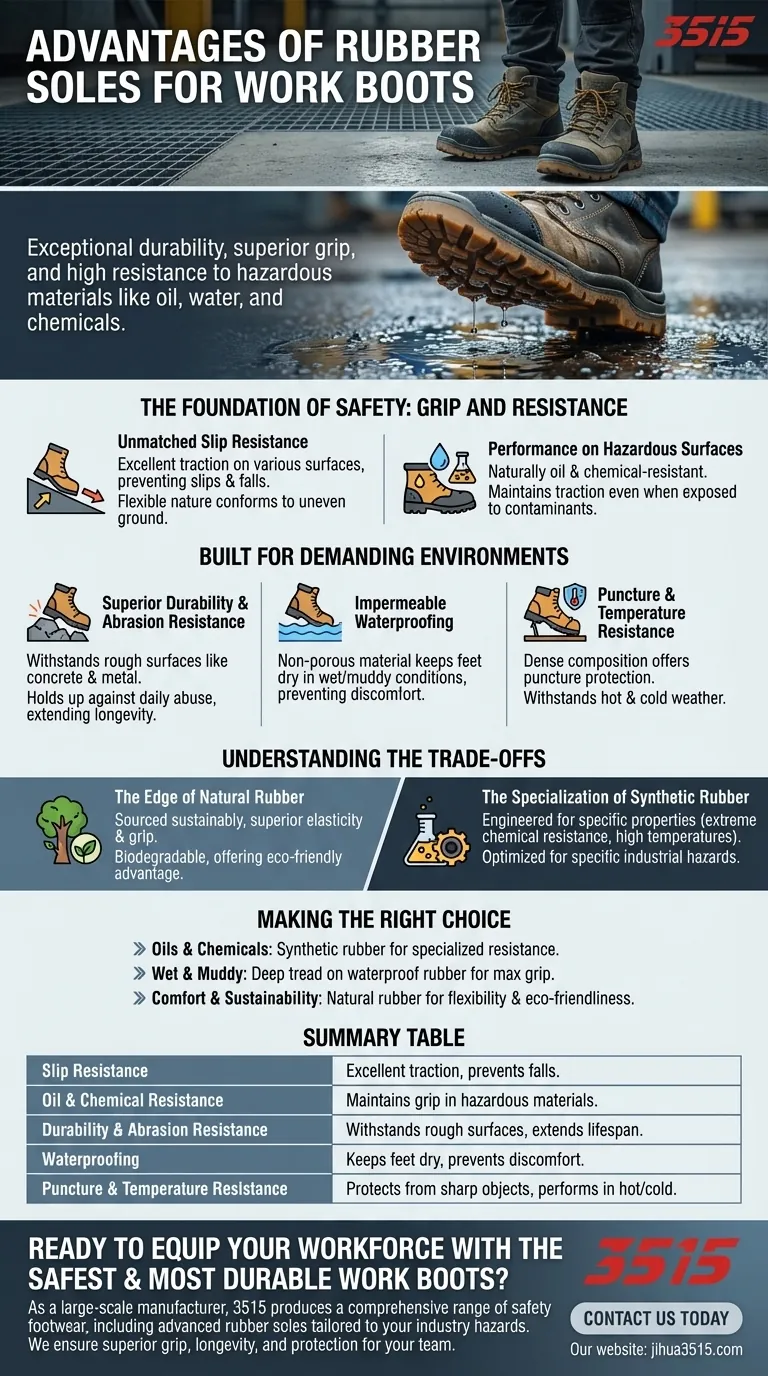

The Foundation of Safety: Grip and Resistance

The most critical function of a work boot is to keep you safe and stable. Rubber's inherent properties make it uniquely suited for this task.

Unmatched Slip Resistance

Rubber provides excellent traction on a wide variety of surfaces. This natural grip is essential for preventing slips and falls, especially in unpredictable conditions.

Its flexible nature allows the sole to conform to uneven ground, maximizing surface contact and stability.

Performance on Hazardous Surfaces

Many work environments contain fluids that can create dangerous, slick surfaces. Rubber soles are naturally oil-resistant and chemical-resistant.

This ensures that the sole's material does not degrade and maintains its traction even when exposed to contaminants.

Built for Demanding Environments

Work boots are subjected to constant punishment. Rubber soles are engineered to withstand this daily abuse while protecting the wearer.

Superior Durability and Abrasion Resistance

Rubber is highly durable and abrasion-resistant, meaning it holds up against rough surfaces like concrete, gravel, and metal grating without wearing down quickly.

This resistance to wear and tear directly contributes to the longevity of the work boot, making it a sound investment.

Impermeable Waterproofing

As a non-porous material, rubber is completely waterproof. This is critical for keeping feet dry in wet or muddy conditions, preventing discomfort and potential health issues.

This quality makes rubber the ideal material for both the sole and, in many cases, the entire boot upper in occupations that involve constant exposure to water.

Puncture and Temperature Resistance

The dense composition of rubber offers a degree of puncture resistance, protecting the foot from sharp objects on the ground.

Natural rubber compounds also withstand a wide range of weather conditions, maintaining their flexibility and performance in both hot and cold environments.

Understanding the Trade-offs

While "rubber" is used as a general term, the distinction between natural and synthetic rubber involves different advantages.

The Edge of Natural Rubber

Sourced sustainably from rubber trees, natural rubber is often noted for its superior elasticity and grip.

It is also biodegradable, offering an eco-friendly advantage over purely synthetic materials that persist in the environment.

The Specialization of Synthetic Rubber

Synthetic rubber compounds can be engineered to enhance specific properties. For example, some blends are formulated for extreme chemical resistance or to withstand very high temperatures.

These specialized formulas allow manufacturers to create soles optimized for very specific industrial hazards.

Making the Right Choice for Your Goal

Selecting the correct boot means matching its features to the primary demands of your job.

- If your primary focus is safety around oils and chemicals: Prioritize a synthetic rubber sole specifically rated for oil and chemical resistance.

- If your primary focus is outdoor work in wet and muddy conditions: Look for a boot with a deep, aggressive tread pattern on a waterproof rubber sole for maximum grip.

- If your primary focus is comfort and sustainability on varied terrain: A natural rubber sole can offer superior flexibility and grip while being a more eco-friendly choice.

Ultimately, choosing a work boot with a rubber sole is an investment in your safety, comfort, and daily performance on the job.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Slip Resistance | Excellent traction on various surfaces, preventing slips and falls. |

| Oil & Chemical Resistance | Maintains grip and integrity when exposed to hazardous materials. |

| Durability & Abrasion Resistance | Withstands rough surfaces, extending the boot's lifespan. |

| Waterproofing | Keeps feet dry in wet conditions, preventing discomfort. |

| Puncture & Temperature Resistance | Protects from sharp objects and performs in hot/cold weather. |

Ready to equip your workforce with the safest and most durable work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including those with advanced rubber soles tailored to your specific industry hazards.

We ensure superior grip, longevity, and protection for your team. Contact us today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

People Also Ask

- What are the disadvantages of leather shoe soles? Key Limitations in Traction & Durability

- What is the physical mechanism behind incorporating small rubber particles on compression socks for balance function?

- What historical breakthrough in 1844 contributed to modern shoe sole manufacturing? The Vulcanization Revolution

- How does a friction coefficient test rig facilitate the assessment of slip resistance in rubber footwear soles?

- How does natural rubber contribute to shock absorption in footwear? Unlock Superior Comfort & Durability

- Why are sturdy sole shoes recommended for patients during the post-operative recovery phase of a Lisfranc fracture?

- What is the primary function of high-performance rubber outsoles? Master Traction in Extreme Weather

- What are the technical advantages of incorporating nano-clay or carbon nanotubes into bio-based shoe sole materials?