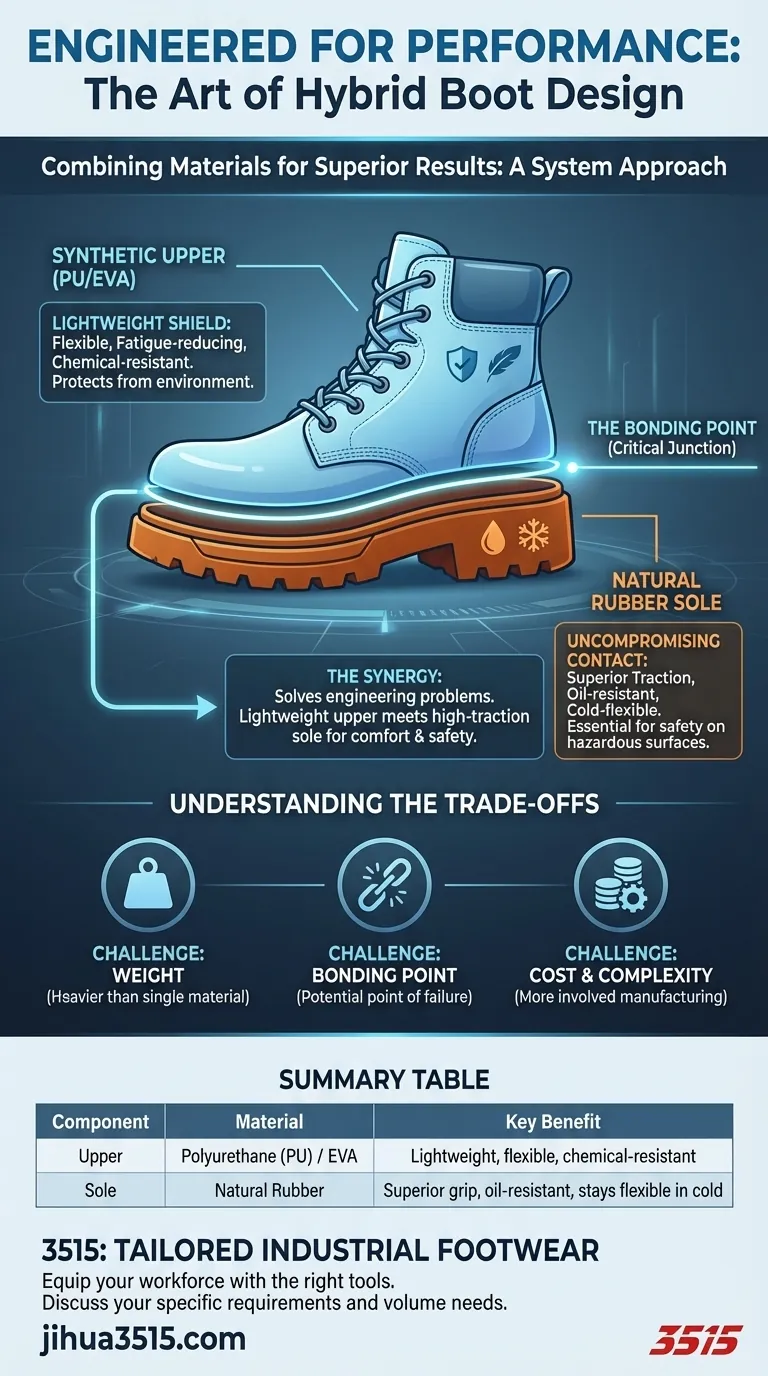

The most effective high-performance boots are not made from a single material, but are engineered systems. They strategically combine synthetic uppers, like Polyurethane (PU) or EVA, with natural rubber soles. This specific combination is designed to deliver enhanced chemical resistance and superior traction on hazardous surfaces like oil, ice, or water.

The core principle of modern boot design is specialization. Materials are chosen for specific parts of the boot to leverage their unique strengths—lightweight flexibility for the upper and uncompromising grip for the sole—creating a final product that outperforms any single-material solution.

The "System" Approach to Boot Design

A high-performance boot should be viewed as an integrated system, not a single object. Each component is chosen to fulfill a distinct and critical function. The magic happens where these specialized materials meet.

The Upper: A Shield of Lightweight Resistance

The upper part of the boot is responsible for protecting your foot from the environment. Materials like Polyurethane (PU) and Ethylene-vinyl acetate (EVA) are chosen for this role.

These synthetics are exceptionally lightweight and flexible, which reduces fatigue over a long day. Crucially, they possess excellent resistance to degradation from oils, chemicals, and other industrial substances.

The Sole: The Point of Uncompromising Contact

The sole is your only connection to the ground, where safety and stability are paramount. For this, natural rubber is often the superior choice.

Natural rubber maintains its flexibility in freezing temperatures and has a high coefficient of friction. This translates directly into reliable, non-slip traction on slick or frozen surfaces where other materials would fail.

Why This Combination Is So Effective

This hybrid design solves a fundamental engineering problem. A boot made entirely of natural rubber would be incredibly heavy and cumbersome. A boot made entirely of lightweight EVA would lack the necessary grip and durability for demanding environments.

By fusing a lightweight, chemically-resistant PU or EVA upper to a rugged, high-traction rubber sole, designers create a boot that is both comfortable and exceptionally safe.

Understanding the Inherent Trade-offs

While combining materials offers superior performance, it's essential to understand the compromises involved. No design choice is without its trade-offs.

The Challenge of Weight

The primary benefit of a natural rubber sole—its dense, durable composition—is also a source of its main drawback: weight. A hybrid boot will almost always be heavier than one made entirely from a lighter synthetic like EVA.

The Bonding Point

The seam where the upper is bonded to the sole is the most critical point in the manufacturing process. If this bond is not executed perfectly, it can become a point of failure, leading to delamination and water ingress over time.

Cost and Complexity

Manufacturing a boot from multiple materials is inherently more complex and costly than a simple, single-material injection molding process. This increased performance and durability often comes at a higher price point.

Making the Right Choice for Your Goal

Selecting the correct boot means matching its material composition to your specific needs.

- If your primary focus is safety in industrial settings: Prioritize a boot with a dedicated natural rubber sole for its proven oil resistance and superior grip.

- If your primary focus is extreme cold: Ensure the boot combines an insulated upper with a natural rubber sole rated for low temperatures to maintain flexibility and traction.

- If your primary focus is all-day comfort for light-duty work: A lighter, single-material PU or EVA boot may offer sufficient performance without the added weight of a rubber sole.

Understanding this material synergy allows you to choose your footwear not just as a piece of apparel, but as an engineered tool for the task at hand.

Summary Table:

| Component | Material | Key Benefit |

|---|---|---|

| Upper | Polyurethane (PU) / EVA | Lightweight, flexible, chemical-resistant |

| Sole | Natural Rubber | Superior grip, oil-resistant, stays flexible in cold |

Need high-performance boots tailored for your industrial or safety needs?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots, engineered with the precise material combinations discussed here to ensure durability, comfort, and protection.

Let us help you equip your workforce with the right tools. Contact our experts today to discuss your specific requirements and volume needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are some hazards that can cause slips and falls in the workplace? Prevent Costly Injuries & Boost Safety

- What is the difference between side-zip and lace-up security guard safety boots? Speed vs. Perfect Fit

- What are the requirements for oilfield boots? Essential Safety & Durability Features

- What are the advantages of rubber soles for work boots? Unbeatable Grip & Durability

- What were some early hazards that safety footwear addressed? A Guide to Essential Foot Protection