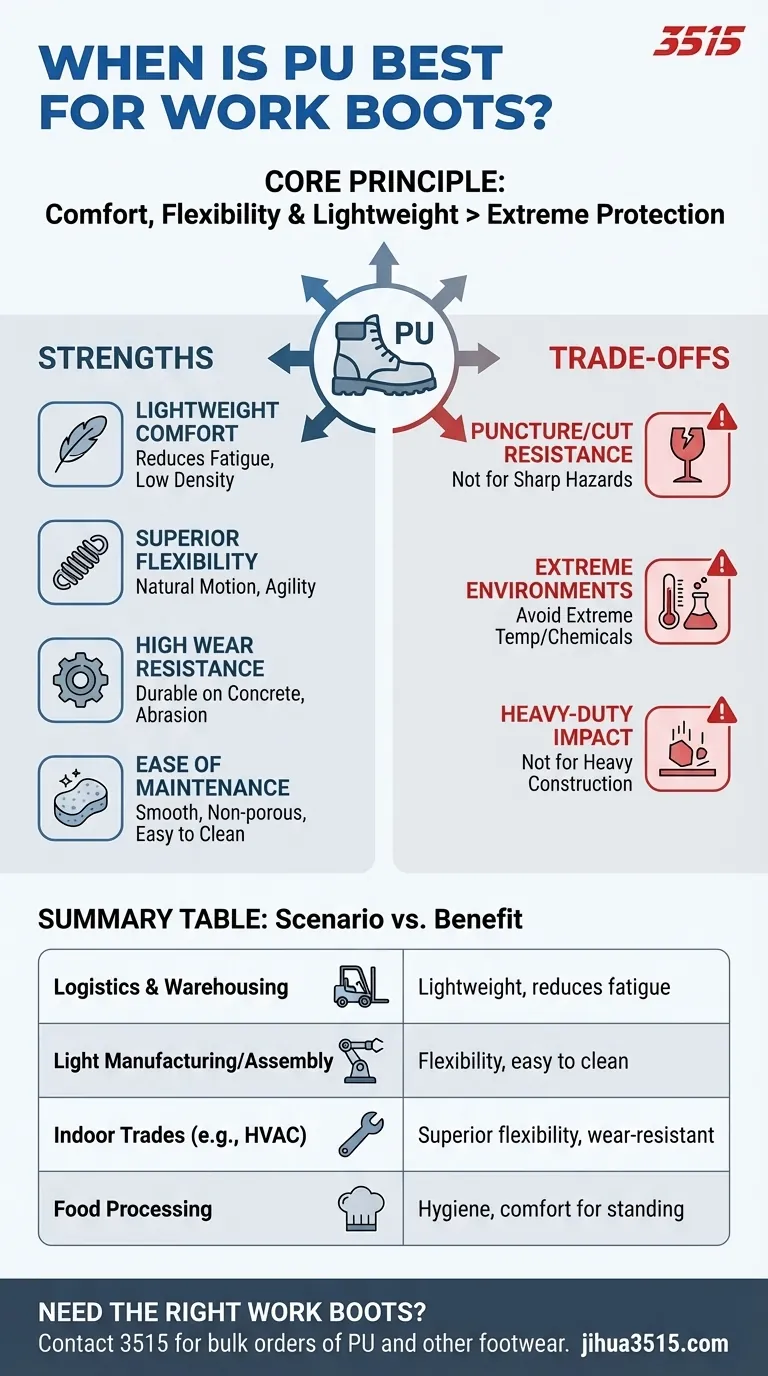

In short, Polyurethane (PU) is most suitable for work boots in environments where long-lasting comfort, flexibility, and lightweight design are more critical than protection from extreme hazards. It excels in light-duty roles that require long hours of standing or walking, such as in logistics, light manufacturing, and indoor trades.

The core principle is this: PU prioritizes reducing worker fatigue through its lightweight and flexible properties. It is the ideal material for jobs that are demanding on your feet but not on your boot's protective capabilities.

The Core Strengths of PU in Work Boots

To understand where PU fits, you need to understand its fundamental properties. Its value comes from a unique combination of comfort and resilience that other materials often struggle to balance.

Unmatched Lightweight Comfort

PU has a low-density structure, which makes it significantly lighter than traditional materials like solid rubber or leather.

This directly translates to reduced foot fatigue over a long workday. For workers who are constantly on their feet, this can be the single most important factor in their footwear.

Superior Flexibility and Elasticity

PU soles and uppers allow for a more natural range of foot motion. This flexibility is crucial for jobs that require agility, frequent crouching, or climbing.

Unlike stiffer materials, PU moves with the wearer, preventing the restrictive feeling that can lead to discomfort and soreness after a full shift.

High Wear Resistance

Despite its light weight, PU offers excellent resistance to abrasion and daily wear and tear.

This makes it a durable choice for work environments with common surfaces like concrete floors in warehouses or workshops.

Ease of Maintenance

The non-porous, smooth surface of PU makes it inherently easy to clean.

This is a practical benefit in environments that may be dusty or prone to light, non-corrosive spills, such as food processing or general assembly lines.

Understanding the Trade-offs

No material is perfect for every scenario. Being an effective advisor means acknowledging the limitations of PU to prevent its misuse in unsafe conditions.

Puncture and Cut Resistance

The very flexibility that makes PU comfortable also means it does not offer the same level of protection against sharp objects as denser rubber or reinforced leather boots.

In environments with risks from nails, scrap metal, or sharp debris, a boot with a dedicated puncture-resistant plate is non-negotiable, and the upper material should be more robust.

Extreme Environment Suitability

PU is not the optimal choice for work involving extreme temperatures or harsh chemicals.

It does not provide the same thermal insulation as specialized rubber compounds, nor does it have the resistance to corrosive industrial chemicals that other purpose-built materials do.

Heavy-Duty Impact Protection

While suitable for light industry, PU boots are generally not designed for the extreme impacts and abrasion common in heavy construction, demolition, or logging.

These high-hazard fields require boots built with a primary focus on maximum protection, where the added weight of materials like thick leather and steel is a necessary trade-off.

Making the Right Choice for Your Work Environment

Your decision should be based on a clear-eyed assessment of your daily tasks and the potential hazards you face.

- If your primary focus is all-day comfort for walking and standing: PU is likely your best choice for roles in warehouses, logistics, light assembly, or indoor trades.

- If your primary focus is basic waterproofing for short-term or occasional use: A simpler material like PVC may be a more cost-effective solution.

- If your primary focus is maximum protection from impact, punctures, or extreme conditions: You must look beyond PU to specialized boots made from reinforced leather or heavy-duty rubber.

Ultimately, matching the material's strengths to your job's specific demands ensures both safety and comfort on the job.

Summary Table:

| Scenario | Why PU is Suitable | Key Benefit |

|---|---|---|

| Logistics & Warehousing | Long hours of walking/standing on concrete | Lightweight, reduces fatigue |

| Light Manufacturing/Assembly | Indoor, minimal puncture/chemical risk | Flexibility, easy to clean |

| Indoor Trades (e.g., electrical, HVAC) | Agility and comfort are priorities | Superior flexibility, wear-resistant |

| Food Processing | Non-porous, easy to clean surfaces | Hygiene, comfort for standing |

Need the right work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including PU models perfect for light-duty roles requiring all-day comfort.

We can help you source durable, comfortable work boots that match your specific job demands. Contact our experts today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are signs that work boots need replacement? Don't Risk Your Safety on Worn-Out Footwear

- What are the common materials used for work boot soles? A Guide to Durability, Comfort & Safety

- What are the advantages of the Powerwelt pull-on boots? Unmatched Convenience & Durability

- How did engineer boots evolve in postwar culture? From Workwear to Rebel Icon

- What safety features should hazard workers look for in lace-up work boots? A Guide to Certified Protection

- Which material is recommended for work boots in cold, wet environments? Neoprene for Superior Warmth

- Are work boots suitable for everyday wear? Find Your Perfect Durable & Comfortable Boot

- What role do supportive insoles play in work boots? Upgrade Your Footwear for All-Day Comfort