Ultimately, you should replace your work boots when their core protective and supportive features are compromised. Key indicators include visible damage to the safety toe, significant cracks or tears in the material, a worn-out outsole that has lost its traction, or a noticeable decrease in comfort and support that leads to foot pain.

Your work boots are a critical piece of personal protective equipment. The decision to replace them isn't about appearance; it's a calculated assessment of whether they can still protect you from injury and support your physical health.

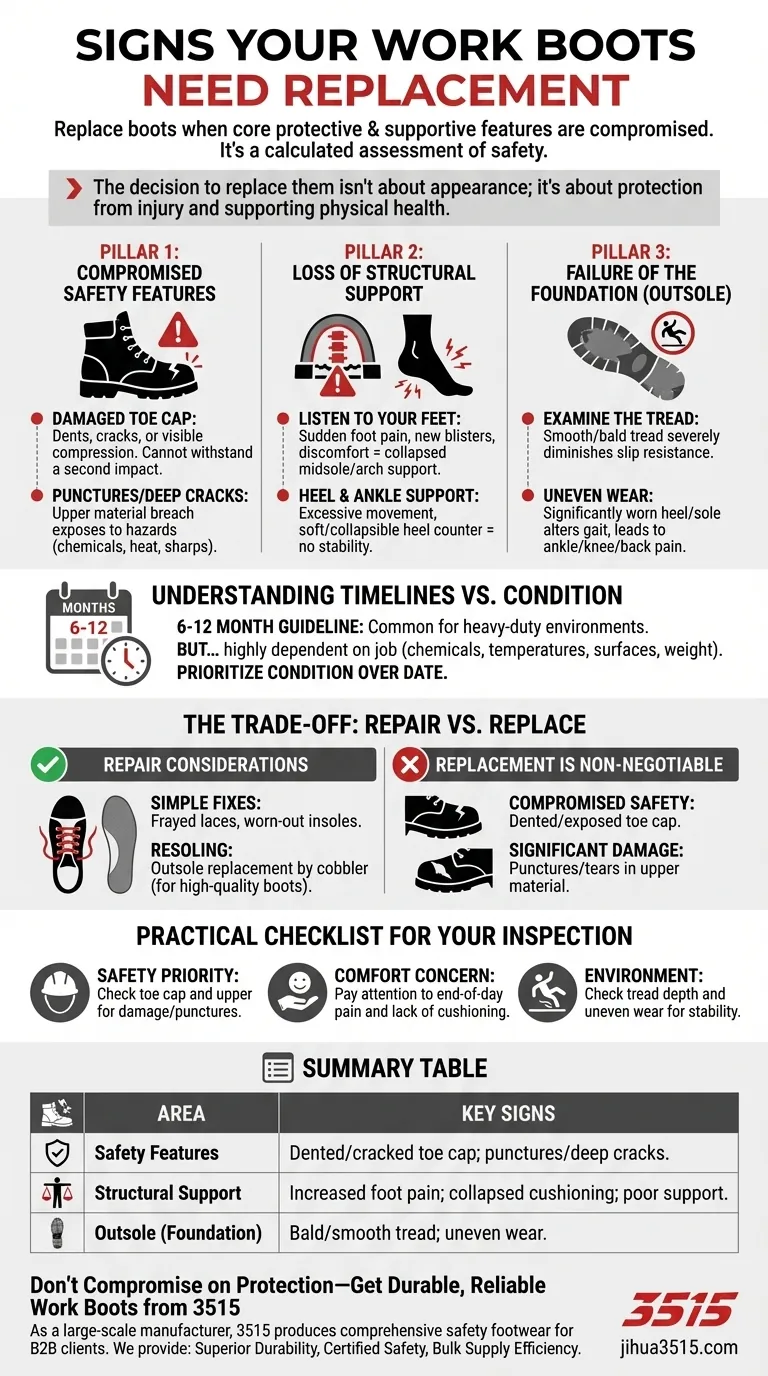

The Three Pillars of Boot Integrity

Think of your boot's lifespan in terms of three core functions. When any one of these pillars fails, it's time for a replacement.

Pillar 1: Compromised Safety Features

This is the most critical area of inspection. The safety components are non-negotiable and, once damaged, often cannot be repaired.

Look for damage to the toe cap. Any dents, cracks, or visible compression in a steel or composite toe mean its protective value is gone. It will not withstand a second impact.

Inspect for punctures or deep cracks. The upper material (often leather) shields you from chemicals, heat, and sharp objects. Any breach in this barrier exposes you to workplace hazards.

Pillar 2: Loss of Structural Support

A boot's internal structure prevents fatigue and long-term musculoskeletal issues. When it breaks down, your body pays the price.

Listen to your feet. A sudden increase in foot pain, new blisters, or general discomfort is a clear signal. This means the midsole cushioning and arch support have collapsed.

Check the heel and ankle support. The boot should feel snug and supportive. If your foot moves around excessively or the heel counter feels soft and collapsible, the boot is no longer providing stability.

Pillar 3: Failure of the Foundation (The Outsole)

The outsole is your connection to the ground. Its failure directly impacts your stability and safety.

Examine the tread. Just like car tires, boot treads wear down. Once the patterns are smooth or "bald," the boot's slip resistance is severely diminished, creating a major safety risk.

Look for uneven wear. If one side of the heel or sole is worn down significantly more than the other, it can alter your gait. This can lead to pain not just in your feet, but in your ankles, knees, and back.

Understanding Timelines vs. Condition

You will often hear general guidelines for replacing work boots, but these are starting points, not absolute rules.

The 6-12 Month Guideline

For professionals in heavy-duty environments, replacing boots every six to twelve months is a common recommendation. This assumes daily, demanding use.

Why Your Experience Varies

This timeline is highly dependent on your specific job. Factors like exposure to harsh chemicals, extreme temperatures, walking on abrasive surfaces like concrete versus soft ground, and your body weight all accelerate wear. Always prioritize the physical condition of the boot over a calendar date.

The Trade-off: Repair vs. Replace

Not every issue requires a new pair of boots, but it's crucial to know the difference between a simple fix and a terminal failure.

When to Consider Repair

Minor issues can often be addressed. Frayed laces and worn-out insoles are simple and inexpensive to replace. For high-quality boots, a professional cobbler can sometimes replace a worn-out outsole, a process known as resoling.

When Replacement is Non-Negotiable

Never attempt to repair a compromised safety feature. If the protective toe cap is dented or exposed, or if there are significant punctures or tears in the upper material, the boot's integrity is gone. It must be replaced immediately.

A Practical Checklist for Your Next Inspection

Use this checklist to make a clear, objective decision based on your primary needs.

- If your top priority is safety compliance: Inspect the toe cap for any damage and the upper for any punctures or deep cracks that compromise its protective barrier.

- If your main concern is all-day comfort: Pay attention to how your feet feel at the end of the day; new aches or a lack of cushioning are clear signs the internal support has failed.

- If you work in slippery or uneven environments: Check the outsole's tread depth and look for any uneven wear patterns that could affect your stability.

Trust your assessment; your safety and well-being depend on the foundation you stand on.

Summary Table:

| Area of Concern | Key Signs for Replacement |

|---|---|

| Safety Features | Dented/cracked toe cap; punctures/deep cracks in upper material. |

| Structural Support | Increased foot pain; collapsed cushioning; poor heel/ankle support. |

| Outsole (Foundation) | Bald or smooth tread; uneven wear patterns affecting stability. |

Don't Compromise on Protection—Get Durable, Reliable Work Boots from 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, built to withstand demanding environments and protect your workforce.

We provide:

- Superior Durability: Boots engineered for long-lasting performance.

- Certified Safety: Meets and exceeds industry safety standards.

- Bulk Supply Efficiency: Reliable, high-volume manufacturing for your business needs.

Ensure your team has the foundational protection they need. Contact 3515 today to discuss your work boot requirements and get a quote.

Visual Guide

Related Products

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes

- What are the signs that work boots need replacement? Protect Your Feet and Safety on the Job

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- What are steel toe work boots and who should wear them? Essential PPE for Hazardous Jobs