The most common materials for work boot soles are Rubber, Thermoplastic Polyurethane (TPU), and Ethylene Vinyl Acetate (EVA). Each is chosen for a specific combination of durability, weight, and resistance to environmental factors like oil, heat, and abrasion. These materials are often used in different parts of the sole—the outsole and the midsole—to create a boot that is both protective and comfortable.

The core decision in work boot sole materials is not about finding one "best" material, but about understanding the trade-off between durability and comfort. Harder materials like rubber and TPU offer superior protection and longevity, while softer materials like EVA provide cushioning and reduce weight.

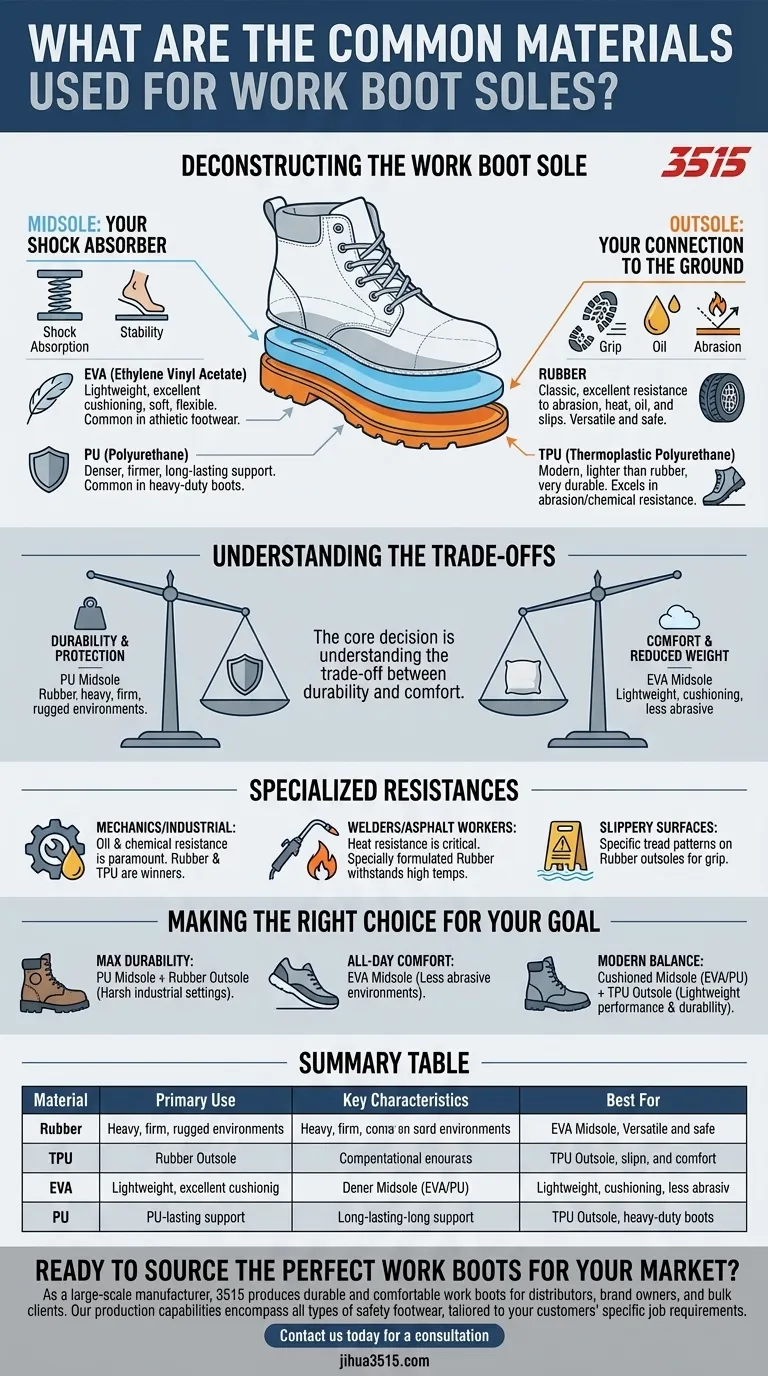

Deconstructing the Work Boot Sole

A boot sole isn't a single piece of material. It typically consists of two key layers: the midsole for cushioning and the outsole for grip and durability. The choice of material for each layer directly impacts your daily experience on the job.

The Midsole: Your Shock Absorber

The midsole is the layer between your foot and the hard ground. Its primary job is shock absorption and providing a comfortable, stable platform.

EVA (Ethylene Vinyl Acetate) EVA is a foam-like material prized for its lightness and excellent cushioning. It feels soft and flexible underfoot, which is why it's a popular choice in athletic footwear.

Polyurethane (PU) Polyurethane is a denser, firmer, and more durable foam than EVA. It provides less initial "cushy" feeling but holds its shape and support for much longer, making it common in heavy-duty hiking and work boots.

The Outsole: Your Connection to the Ground

The outsole is the part that makes direct contact with the ground. It must provide traction and resist wear, punctures, and chemicals.

Rubber Rubber is the classic, time-tested material for outsoles. It offers excellent resistance to abrasion, heat, oil, and slips, making it an incredibly versatile and safe choice for most work environments.

TPU (Thermoplastic Polyurethane) TPU is a modern alternative that is lighter than rubber but still very durable. It excels in resisting abrasion, splitting, and exposure to oil and chemicals, offering a great balance of performance and reduced weight.

Understanding the Trade-offs

Choosing the right boot means understanding the compromises inherent in each material. No single material excels at everything.

Durability vs. Comfort

The most significant trade-off is between long-term durability and immediate comfort.

- Polyurethane (PU) midsoles and Rubber outsoles are workhorses. They are heavier and firmer but will withstand years of abuse, making them ideal for rugged, abrasive environments.

- EVA midsoles are significantly lighter and provide better cushioning, reducing fatigue during long days on your feet. However, EVA can compress and lose its supportive qualities more quickly than PU.

Weight vs. Protection

A lighter boot reduces fatigue, but that weight reduction often comes at a cost.

- TPU outsoles are a popular way to reduce weight without sacrificing significant chemical and abrasion resistance compared to traditional rubber.

- Boots that heavily feature EVA in both the midsole and outsole are exceptionally lightweight but offer the least protection against punctures and aggressive wear.

Specialized Resistances

Your specific work environment dictates the non-negotiable features you need.

- For mechanics or industrial workers: Oil and chemical resistance is paramount. Rubber and TPU are the clear winners here.

- For welders or asphalt workers: Heat resistance is critical. Specially formulated Rubber compounds are designed to withstand high temperatures.

- For slippery surfaces: Look for specific tread patterns on Rubber outsoles designed to maximize grip and channel away liquids.

Making the Right Choice for Your Goal

Your primary job function should guide your selection.

- If your primary focus is maximum durability and safety in harsh industrial settings: Choose a boot with a Polyurethane (PU) midsole and a solid Rubber outsole.

- If your primary focus is all-day comfort and reduced fatigue in less abrasive environments: A boot with an EVA midsole will provide superior cushioning and be noticeably lighter.

- If your primary focus is a modern balance of lightweight performance and durability: Look for a boot that combines a cushioned midsole (EVA or PU) with a strong, abrasion-resistant TPU outsole.

Ultimately, the ideal work boot sole is an engineered system that gives you the specific protection you need without causing unnecessary fatigue.

Summary Table:

| Material | Primary Use | Key Characteristics | Best For |

|---|---|---|---|

| Rubber | Outsole | Excellent abrasion, heat, oil, and slip resistance | Harsh industrial settings, welding, slippery surfaces |

| TPU (Thermoplastic Polyurethane) | Outsole | Lightweight, durable, strong oil/chemical resistance | Modern boots needing a balance of weight and protection |

| EVA (Ethylene Vinyl Acetate) | Midsole | Lightweight, superior cushioning, soft underfoot | All-day comfort, reduced fatigue in less abrasive jobs |

| PU (Polyurethane) | Midsole | Durable, firm support, long-lasting shape | Heavy-duty work, rugged environments requiring maximum support |

Ready to Source the Perfect Work Boots for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and comfortable work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, allowing us to create the ideal sole system—whether you need maximum durability with a PU midsole and rubber outsole, or all-day comfort with an EVA midsole—tailored to your customers' specific job requirements.

Let's discuss your project and how we can deliver high-quality, reliable work boots that meet your exact specifications.

Contact us today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the pros of Cement Construction? Discover Lightweight, Flexible Footwear

- Why are PVC boots a good option for farm work? Unbeatable Chemical & Water Protection

- What type of safety shoe is recommended for workers exposed to heavy machinery? Steel Toe Boots for Ultimate Protection

- What is a recommended color for work boots? Discover the Best Choice for Durability & Professionalism

- What features should work boots have for cold or hot working conditions? A Guide to Temperature-Specific Safety

- What types of electrical hazard protection are available in work boots? EH vs. SD Safety Explained

- How is all-around comfort achieved in western boots? Discover the Integrated Comfort System

- Why is wearing proper construction footwear important in accident-prone job sites? Protect Your Workforce