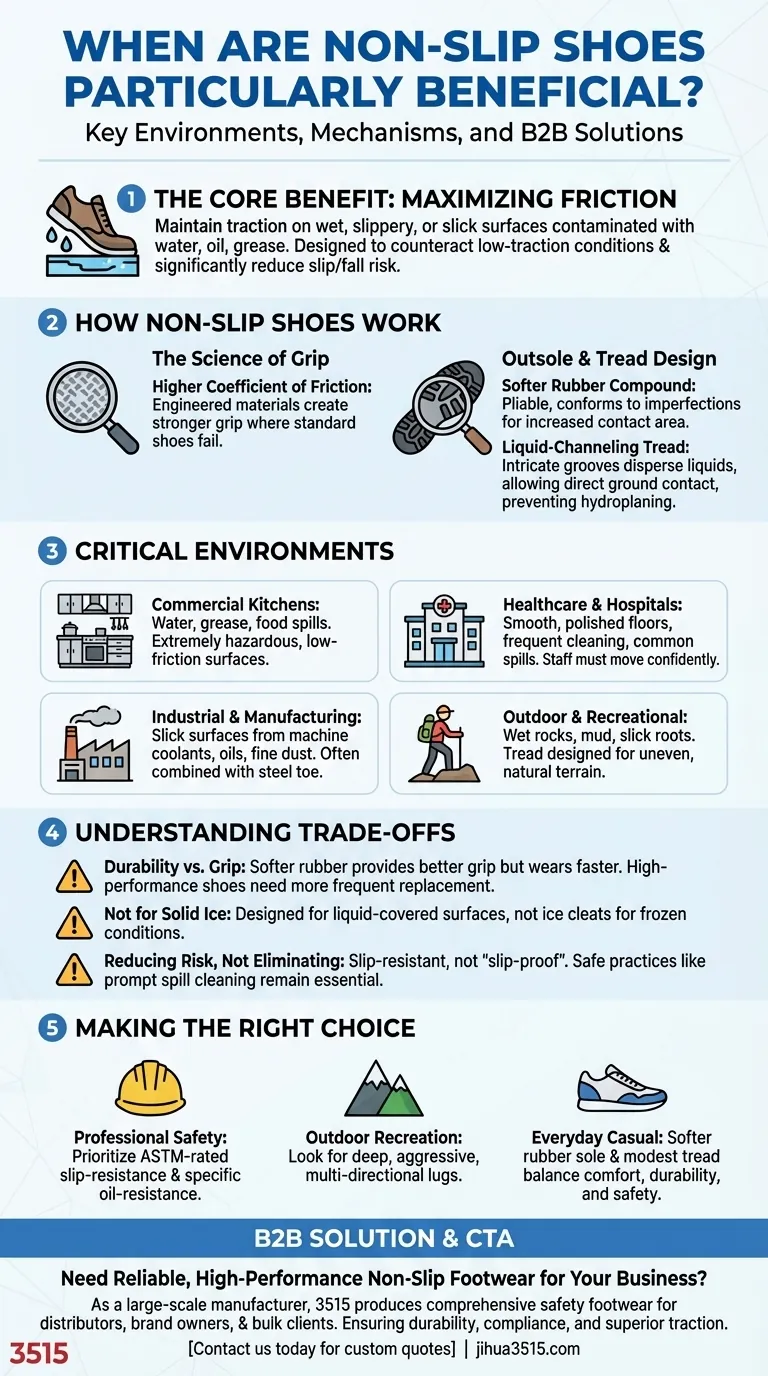

In short, non-slip shoes are most beneficial in any environment where the floor surface is likely to be contaminated with water, oil, grease, or other liquids. They are specifically designed to maintain traction on wet, slippery, or slick surfaces, making them essential in professional settings like commercial kitchens and hospitals, as well as for recreational activities such as hiking on damp ground.

The core benefit of non-slip shoes isn't just about the shoe itself, but about the interaction between the shoe's outsole and the surface. Their specialized design maximizes the force of friction to counteract hazardous, low-traction conditions and significantly reduce the risk of slips and falls.

How Non-Slip Shoes Actually Work

To understand their benefit, you must first understand the mechanism that makes them effective. It’s a combination of material science and engineering design.

The Science of Grip

At its core, slip resistance is about maximizing the coefficient of friction—a measure of how much force is needed to slide one surface over another.

Non-slip shoes are engineered with materials and patterns that create a higher coefficient of friction against slippery floors, providing a stronger grip where standard shoes would fail.

The Role of Outsole Material

The material of the outsole is the first line of defense. Most non-slip shoes use a softer rubber compound.

This softer material is more pliable, allowing it to conform better to microscopic imperfections on a floor surface. This increases the total contact area and enhances its gripping ability, especially on smooth, wet floors.

The Importance of Tread Pattern

The second critical element is the design of the tread, or the pattern on the bottom of the shoe.

These patterns feature small, intricate grooves designed to channel liquids away from the point of contact between the shoe and the floor. By dispersing water or oil, the tread allows the solid parts of the outsole to make direct, firm contact with the ground, preventing hydroplaning and preserving traction.

Key Environments Where Slip-Resistance is Critical

While useful in many daily situations, certain environments make non-slip footwear an essential piece of safety equipment.

Professional and Commercial Kitchens

This is the quintessential environment for non-slip shoes. Floors are constantly exposed to a combination of water, grease, and spilled food, creating an extremely hazardous, low-friction surface.

Healthcare and Hospitals

Hospital floors are typically smooth, polished, and frequently cleaned. Spills are common, and staff must move quickly and confidently without the risk of slipping, making non-slip footwear a standard requirement.

Industrial and Manufacturing Floors

In these settings, surfaces can be slick with machine coolants, oils, or fine dust. Non-slip shoes, often combined with a steel toe, are crucial for preventing workplace injuries.

Outdoor and Recreational Activities

For activities like hiking or trail running, especially in damp climates, non-slip shoes are vital. The tread on these shoes is designed to grip onto uneven and wet surfaces like rocks, mud, and slick roots.

Understanding the Trade-offs

While highly beneficial, it's important to recognize the limitations and trade-offs associated with non-slip footwear.

Durability vs. Grip

The softer rubber compounds that provide excellent grip also tend to wear down faster than the harder rubber found on standard shoes. This means that high-performance non-slip shoes may need to be replaced more frequently to maintain their safety effectiveness.

Not a Solution for Ice

Standard non-slip shoes are designed for liquid-covered surfaces, not solid ice. While they may perform slightly better than a smooth-soled shoe, they are not a substitute for ice cleats or specialized winter boots designed for frozen conditions.

Reducing Risk, Not Eliminating It

It's crucial to understand that these shoes are slip-resistant, not "slip-proof." They dramatically reduce the risk of a fall, but they cannot eliminate it entirely. Safe practices, such as cleaning up spills promptly and walking cautiously, remain essential.

Making the Right Choice for Your Situation

Selecting the correct footwear depends entirely on the primary hazard you face.

- If your primary focus is professional safety (e.g., kitchens, hospitals): Prioritize shoes with an official slip-resistance rating (like ASTM standards) and specific oil-resistance.

- If your primary focus is outdoor recreation (e.g., hiking): Look for a shoe with deep, aggressive, multi-directional lugs designed to grip uneven, natural terrain.

- If your primary focus is everyday casual safety: A shoe with a softer rubber sole and a modest tread pattern offers a great balance of comfort, durability, and enhanced safety on wet pavement.

Ultimately, choosing the right footwear is a proactive step in managing your personal safety in challenging environments.

Summary Table:

| Environment | Primary Hazard | Key Shoe Feature |

|---|---|---|

| Commercial Kitchens | Water, Grease, Oil | Soft rubber sole, liquid-channeling tread |

| Hospitals & Healthcare | Wet, polished floors | ASTM-rated slip-resistant outsole |

| Industrial & Manufacturing | Oils, coolants, dust | Oil-resistant compound, often with steel toe |

| Outdoor Recreation | Wet rocks, mud, trails | Deep, multi-directional lugs for uneven terrain |

Need reliable, high-performance non-slip footwear for your team or business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety and occupational footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of non-slip shoes and boots designed for the demanding conditions described above. We ensure durability, compliance with safety standards, and superior traction.

Contact us today to discuss your specific needs and receive a custom quote. Let us help you enhance workplace safety with footwear you can trust.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- Why might someone choose non-slip shoes over regular footwear? Ensure Workplace Safety and Stability

- What role does professional anti-slip outsole technology play? Reduce Fall Risks with Advanced Grip Engineering

- What is the significance of tread patterns in non-slip shoes? Prevent Slips with Expert Sole Design

- What is the general perception of non-slip shoes in workplace safety? Uncover the Truth About Slip-Resistant Footwear

- How can you perform a slip test on shoes you already own? A Guide to Safer Footwear

- What are the technical mechanisms through which professional footwear with non-slip soles prevents falls? Master Grip

- What are the benefits of specialized shoes for doctors? Enhance Comfort, Safety, and Endurance

- What advantages do specialized work shoes offer? Enhance Safety and Health in High-Risk Industrial Sectors