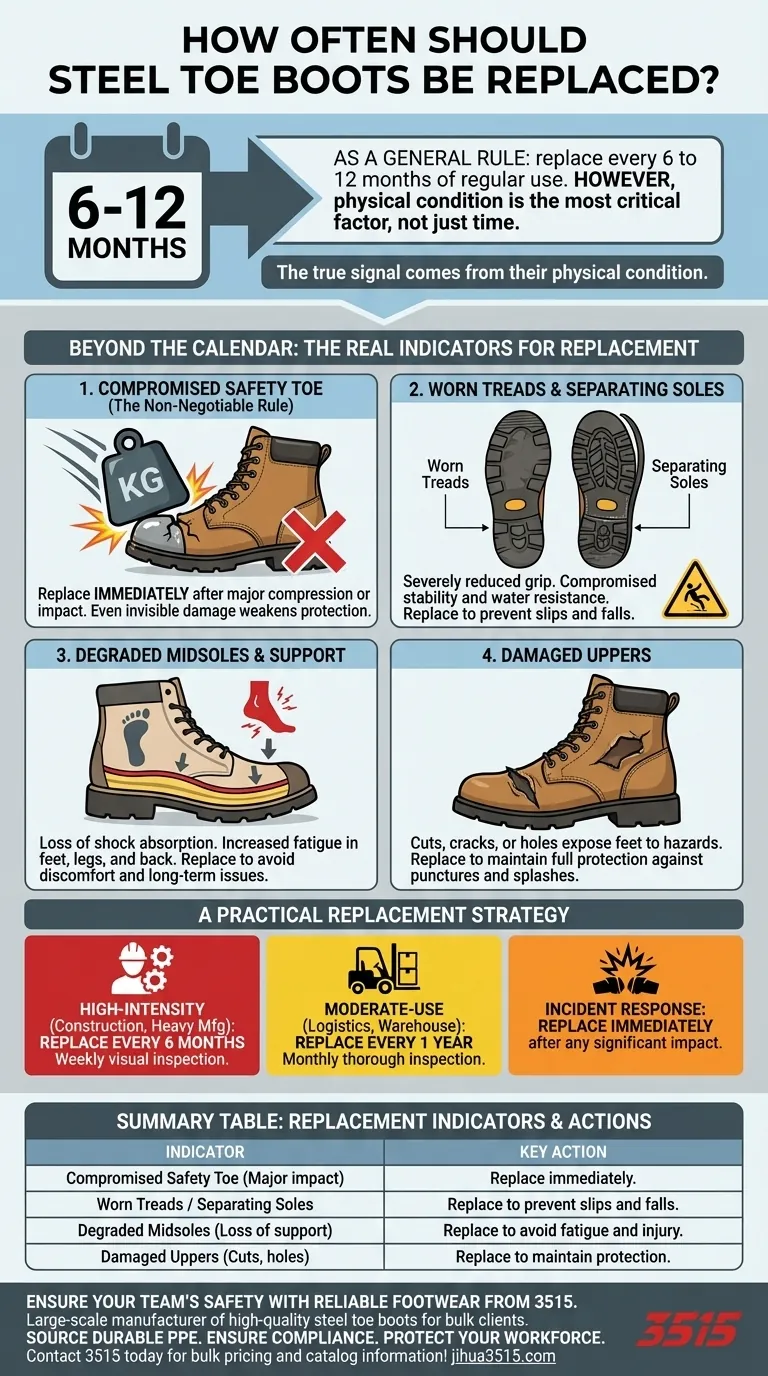

As a general rule, steel toe boots should be replaced every six to twelve months of regular use. However, this timeframe is only a guideline. The most critical factor determining replacement is the boot's physical condition and whether it can still provide the necessary protection.

The calendar is a helpful reminder, but the true signal for replacing your safety boots comes from their physical condition. A boot that can no longer protect you is a liability, regardless of its age.

Beyond the Calendar: The Real Indicators for Replacement

While a 6-12 month replacement cycle is a sound policy for many jobs, relying solely on time can be misleading. A boot's safety is determined by its structural integrity. You must learn to recognize the specific signs of failure.

The Non-Negotiable Rule: A Compromised Safety Toe

This is the most critical inspection point. If your boot sustains a significant impact from a heavy or falling object, the steel toe cap must be considered compromised.

Even if there is no visible damage, the cap's internal structure may be weakened, failing to protect you from the next impact. Replace boots immediately after any major compression or impact event.

Worn Treads and Separating Soles

The outsole provides your primary defense against slips, trips, and falls. Once the tread pattern is significantly worn down, its ability to grip surfaces is severely reduced.

Look for areas that have become smooth or flat. Also, inspect the seam where the sole meets the upper part of the boot; any separation here compromises water resistance and stability.

Degraded Midsoles and Support

The midsole is the boot's shock absorber. Over time, it compresses and loses its ability to cushion your feet and support your arches.

If you feel increased fatigue in your feet, legs, and back, or if the boot feels "flat" and hard inside, the support structure has likely failed. This not only causes discomfort but can contribute to long-term musculoskeletal issues.

Damaged Uppers

The upper portion of the boot protects you from punctures, splashes, and abrasions. Inspect the leather or fabric for deep cuts, cracks, or holes.

Damaged uppers can expose your feet to chemical splashes, water, or physical hazards, negating a key safety feature of the boot.

Understanding the Trade-offs

Making the right decision on boot replacement requires balancing cost against the primary function of Personal Protective Equipment (PPE): your safety.

The Risk of Premature Replacement

Replacing boots too early results in unnecessary costs and waste. If a boot is still in excellent condition with no signs of wear, there is no safety reason to replace it simply because it has reached a certain age.

The Danger of Delayed Replacement

This is the far greater risk. Pushing a worn-out boot past its service life exposes you to severe injury. A failed safety toe can lead to amputation, worn treads can cause a debilitating fall, and a lack of support can create chronic pain. The cost of an injury far exceeds the cost of a new pair of boots.

A Practical Replacement Strategy

Use your work environment and daily tasks to create a smart replacement and inspection schedule.

- If your primary focus is safety in a high-intensity environment (construction, heavy manufacturing): Plan to replace your boots every 6 months and conduct a quick visual inspection weekly.

- If your primary focus is compliance in a moderate-use environment (logistics, warehouse work): Plan for a 1-year replacement cycle and conduct a thorough inspection monthly.

- If your primary focus is responding to incidents: Replace your boots immediately after any event that causes a significant impact or compression to the toe area, regardless of their age.

Ultimately, your personal safety is the only metric that matters.

Summary Table:

| Replacement Indicator | Key Action |

|---|---|

| Compromised Safety Toe (Major impact) | Replace immediately. |

| Worn Treads / Separating Soles | Replace to prevent slips and falls. |

| Degraded Midsoles (Loss of support) | Replace to avoid fatigue and injury. |

| Damaged Uppers (Cuts, holes) | Replace to maintain protection. |

Ensure Your Team's Safety with Reliable Footwear from 3515

Don't let worn-out safety boots become a liability. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality steel toe boots and footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring durability, compliance, and superior protection for high-intensity work environments.

Partner with us to:

- Source durable PPE that stands up to rigorous use.

- Ensure compliance with industry safety standards.

- Protect your workforce with reliable, high-performance footwear.

Ready to equip your team with boots built to last? Contact 3515 today for bulk pricing and catalog information!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the primary purposes of steel toe shoes? Essential Foot Protection for Hazardous Workplaces

- How can you optimize the fit of steel toe boots for better comfort? A Complete Guide to Custom Fit

- How can you quickly break in steel toe boots? A Fast, Pain-Free Method for Comfort

- What are the key benefits of steel toe boots? Unmatched Protection & Durability

- Can steel toe boots be worn in hot conditions? Yes, with the right breathable design.

- How do steel toe and composite toe boots differ in thermal insulation? Composite Toes Are Superior Insulators

- Why are steel toe boots considered durable? Built to Last in the Toughest Conditions

- What are the price differences between steel toe and composite toe boots? A Guide to Choosing the Right Safety Boot