Alright, let's get down to brass tacks. I've been asked about the price difference between steel toe and composite toe boots, and the simple answer is: composite toe boots are generally more expensive. But the real question, the one I'm really wrestling with, is which is the right boot for the job? It's about more than just the price tag; it's about matching the boot's specific properties to the specific hazards and requirements of a particular work environment. The price difference reflects the different materials and benefits.

The Core Difference: Material and Protection

Let's break this down. Steel toe boots use, well, steel. It's the classic, robust choice, offering maximum protection against impacts and compression. The downside? They're heavier. Composite toe boots, on the other hand, employ non-metallic materials like carbon fiber, fiberglass, or plastic. They meet the same ASTM standards for safety, but may offer slightly less absolute impact resistance than steel after the initial impact. (Both provide adequate protection).

Why Composite Boots Cost More

The higher price of composite boots stems from a couple of factors. The materials are more advanced and, frankly, more complex to manufacture. Creating these non-metallic toe caps involves a more involved process than simply stamping out a steel one. This increased complexity, naturally, translates to a higher price point.

Understanding the Trade-offs Beyond Price

This is where the real value lies. Here's a breakdown of the key trade-offs:

- Weight and Comfort: Composite boots are significantly lighter, leading to reduced fatigue over a long workday. Steel boots, in comparison, are noticeably heavier.

- Electrical Hazards: This is crucial. Composite is non-conductive, making it the ONLY choice for electricians or anyone working with live wires. Steel conducts electricity, so you must avoid it.

- Temperature Insulation: Composite doesn't transfer heat or cold, making it superior in extreme temperatures. Steel can become very uncomfortable in both hot and cold conditions.

- Security and Metal Detectors: Composite boots are non-metallic, so they won't set off metal detectors. Great for airport workers or those in high-security environments.

- Ultimate Impact Resistance: Steel offers superior strength against extremely heavy impacts or compression. While both meet safety standards, steel gives you a higher safety margin in the most hazardous environments.

- Durability: The steel cap itself is robust and durable.

Making the Right Choice for Your Job

So, the ideal choice depends on your specific needs:

- If your primary focus is maximum impact protection and budget: Steel toe is the more durable and affordable choice for high-hazard environments like heavy construction.

- If your primary focus is comfort and avoiding electrical hazards: Composite toe is the essential choice for electricians or anyone working long hours on their feet.

- If your primary focus is working in extreme temperatures or passing through metal detectors: The insulating and non-metallic properties of composite toe boots make them the superior option.

Ultimately, choosing the right safety boot is about selecting the right tool for the job – the one that best ensures both your safety and your comfort. As a general rule, composite toe boots are more expensive than their steel toe counterparts. This price difference stems directly from the advanced, non-metallic materials and more complex manufacturing processes required to create composite safety caps that meet rigorous safety standards.

The choice between steel and composite toe boots is not just a matter of price, but a critical assessment of your specific work environment. The higher cost of composite boots buys you specific advantages in weight, temperature insulation, and electrical resistance that are non-negotiable for certain professions.

The Core Difference: Material and Protection

The fundamental distinction between these two types of safety boots lies in the material used for the protective toe cap. This single choice has cascading effects on weight, conductivity, and comfort.

Steel Toe: The Classic Standard

Steel toe caps are the traditional choice for safety footwear. They are made from heavy-duty steel, offering exceptional resistance to impact and compression forces.

This robust protection has long made them the standard in construction, manufacturing, and other industrial settings where heavy hazards are common.

Composite Toe: The Modern Alternative

Composite toe caps are crafted from non-metallic materials like carbon fiber, fiberglass, plastic, or Kevlar. They are engineered to be significantly lighter than steel.

While they meet the same ASTM/OSHA safety requirements for impact and compression, they offer a different set of advantages centered on comfort and environmental resistance.

Why Composite Boots Cost More

The price premium for composite toe boots is a direct result of the technology and materials involved in their production.

Advanced Materials

The materials used in composite toes—such as carbon fiber and Kevlar—are inherently more expensive to produce than the steel used in traditional safety caps.

Complex Manufacturing

Forming these advanced materials into a protective cap that meets strict safety standards is a more intricate and costly process than simply stamping a cap from a piece of steel.

Understanding the Trade-offs Beyond Price

Your budget is only one factor. The right boot depends entirely on the hazards and demands of your job.

Weight and Comfort

Composite boots are considerably lighter than steel toe boots. This reduction in weight can lead to significantly less foot fatigue over a long workday, making them a preferred choice for those who are constantly on the move.

Electrical Hazards

This is a critical, non-negotiable difference. Composite materials do not conduct electricity, making them the only safe option for electricians or anyone working in an environment with a risk of live electrical currents. Steel is a conductor and poses a serious risk in these situations.

Temperature Insulation

Steel readily transfers temperature, becoming uncomfortably cold in winter and hot in the summer. Composite materials provide far better insulation, keeping your feet more comfortable in extreme weather conditions.

Security and Metal Detectors

Because they contain no metal, composite toe boots will not trigger metal detectors. This is a significant convenience for workers in airports, nuclear plants, or other secure facilities that require frequent screenings.

Ultimate Impact Resistance

For sheer strength against a single, heavy impact or crushing force, steel offers the highest level of protection. While both types must pass the same safety standards, steel provides a greater margin of safety in the most hazardous environments.

Durability

Steel toe boots are generally considered more durable over the long term. The steel cap itself is extremely resilient to the wear and tear of a demanding job site.

Making the Right Choice for Your Job

Selecting the correct boot is about matching its features to your daily tasks and potential risks.

- If your primary focus is maximum impact protection and budget: Steel toe is the more durable and affordable choice for high-hazard environments like heavy construction or manufacturing.

- If your primary focus is comfort, mobility, and avoiding electrical hazards: The lightweight, non-conductive properties of composite toe boots make them the essential choice for electricians and workers who walk several miles per day.

- If your primary focus is working in extreme temperatures or passing through metal detectors: The insulating and non-metallic nature of composite toe boots makes them the clearly superior option for your needs.

Ultimately, choosing the right safety boot is an investment in your personal safety and daily comfort on the job.

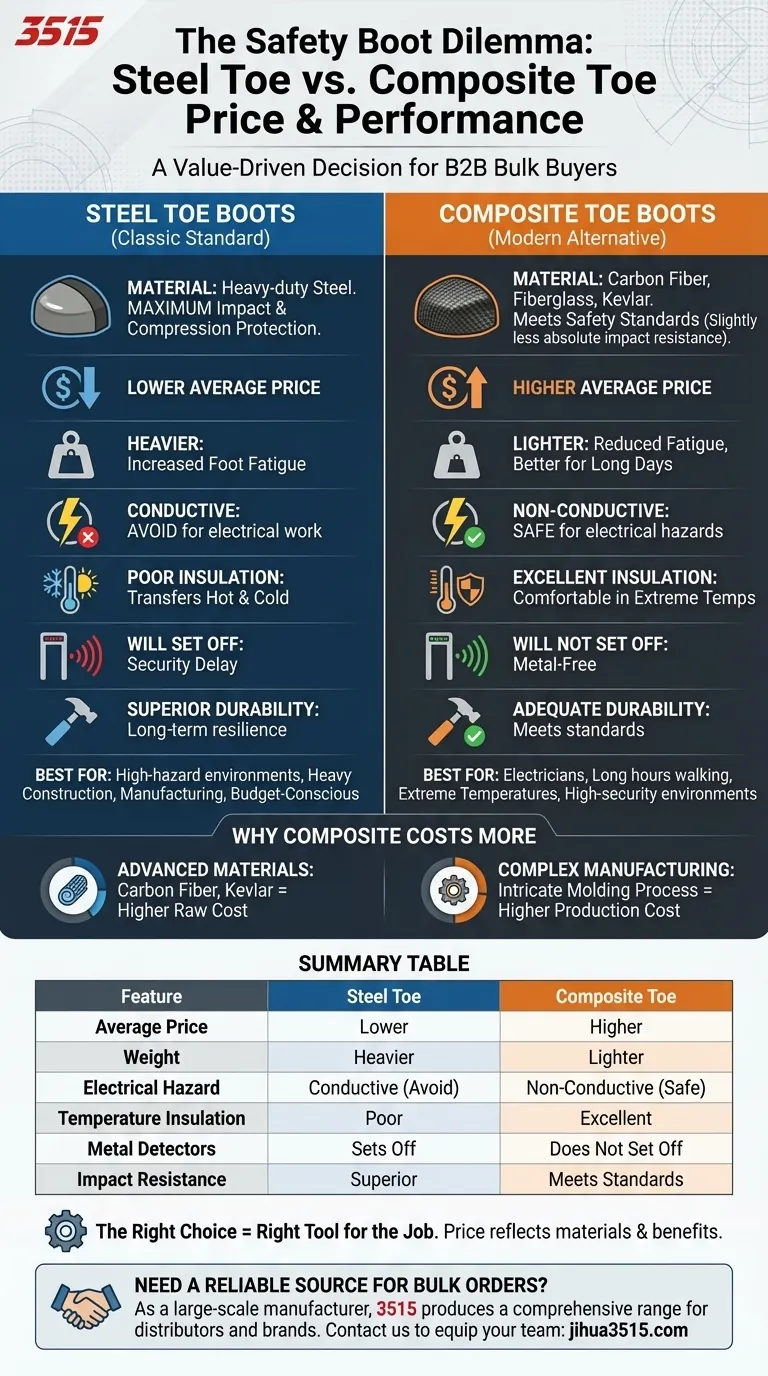

Summary Table:

| Feature | Steel Toe Boots | Composite Toe Boots |

|---|---|---|

| Average Price | Lower | Higher |

| Weight | Heavier | Lighter |

| Electrical Hazard | Conductive (Avoid) | Non-Conductive (Safe) |

| Temperature Insulation | Poor (Transfers Heat/Cold) | Excellent (Insulates) |

| Metal Detectors | Will Set Off | Will Not Set Off |

| Impact Resistance | Superior | Meets Safety Standards |

Need a Reliable Source for Your Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of steel toe and composite toe boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, ensuring you get the right boot for your specific job requirements, combining durability, comfort, and certified protection.

Let us help you equip your team with the right safety gear. Contact our experts today to discuss your needs and get a quote!

Visual Guide

Related Products

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- What is the purpose of front hardeners in safety shoes? Essential Protection for Construction & Welding

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene