The exceptional durability of Goodyear-welted shoes stems from a unique, two-level stitching system. Unlike simpler methods where the sole is attached directly to the upper, this construction uses a leather strip called a welt as a robust intermediary. This welt is first stitched to the shoe's upper and insole, and then a separate, external stitch locks the outsole to the welt, creating a remarkably strong and easily repairable footwear foundation.

The core reason Goodyear-welted shoes last for decades is not just their initial strength, but their inherent design for repair. By isolating the outsole attachment from the shoe's main body, the welt allows for the sole to be replaced multiple times without ever compromising the shoe's core structure.

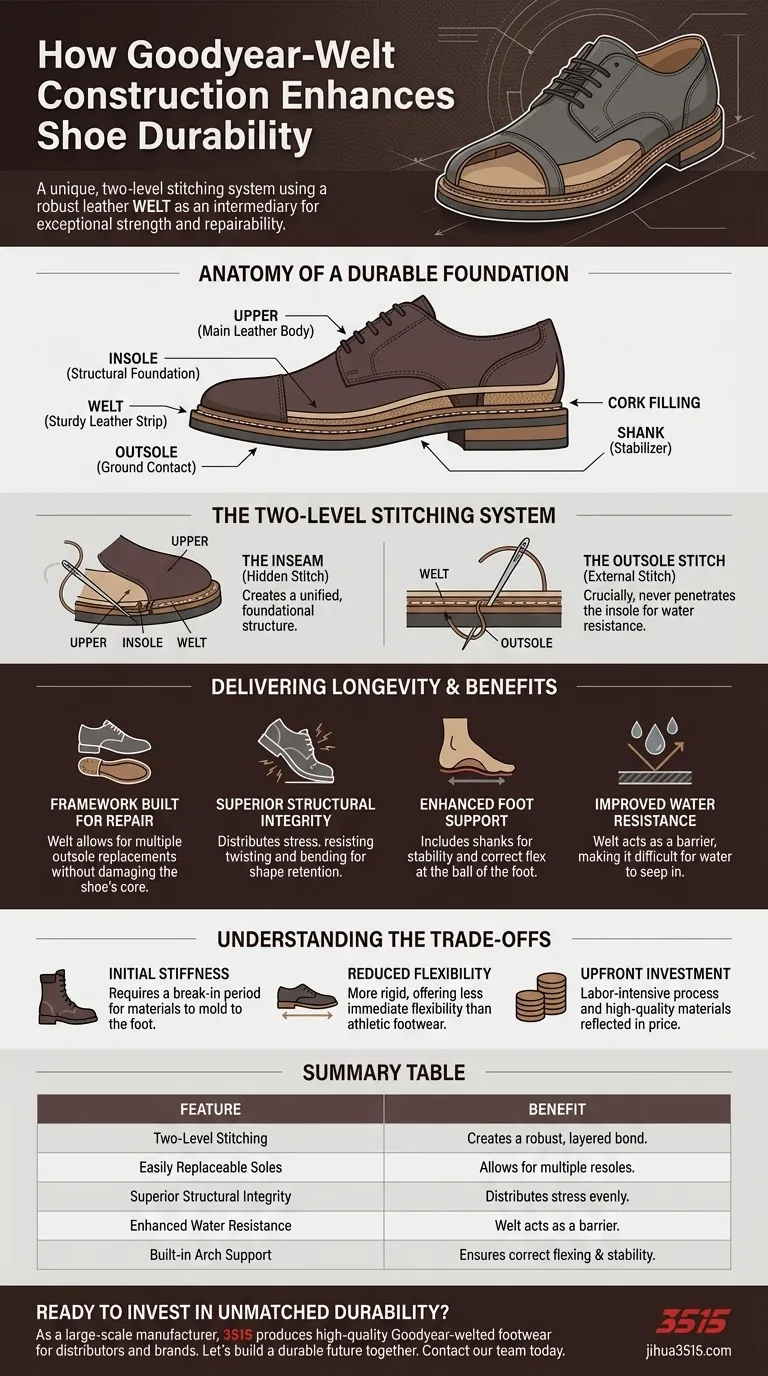

The Anatomy of a Durable Foundation

To understand the durability, you first need to understand the mechanics. The Goodyear welt introduces a specific, methodical process that builds strength in layers.

The Key Components

A Goodyear-welted shoe involves four critical parts working in concert: the upper (the main leather body of the shoe), the insole (the structural foundation your foot rests on), the welt (a sturdy leather strip), and the outsole (the part that contacts the ground).

The First Stitch: The Inseam

The process begins with the most critical connection, which is hidden from view. A strong stitch, called the inseam, is used to securely attach the upper, the insole, and the welt together. This forms the unified, foundational structure of the shoe.

The Second Stitch: The Outsole Stitch

Once the shoe's core is assembled, the outsole is attached. A second, highly durable stitch is run through the welt and the outsole. This external stitch is what you can often see running along the edge of the shoe. Crucially, this stitch never penetrates the insole, which is key for water resistance.

How This Construction Delivers Longevity

The two-level stitching system is not just for show; it directly translates into tangible benefits that define high-quality footwear.

A Framework Built for Repair

This is the single most important factor for longevity. When the outsole wears down from use, a cobbler can simply cut the external outsole stitch and attach a brand-new sole to the existing welt. The shoe's main structure, held together by the original inseam, is never disturbed. This allows for multiple resoles, extending the shoe's life from years to decades.

Superior Structural Integrity

The double-stitching method creates an incredibly strong bond that distributes stress across the entire platform of the shoe. This makes the footwear highly resistant to the twisting and bending forces of daily wear, preventing sole separation and maintaining the shoe's shape over time.

Enhanced Foot Support

Goodyear-welted shoes are built with stabilizing elements, often including both leather and metal shanks between the insole and outsole. These shanks ensure the shoe flexes at the correct point—the ball of the foot—providing a stable platform and preventing the arch from collapsing.

Improved Water Resistance

Because the outsole stitch does not go through to the inside of the shoe, the welt acts as a small wall or barrier. This makes it significantly more difficult for water to seep in from the ground compared to simpler construction methods.

Understanding the Trade-offs

No construction method is without its compromises. Being an informed owner means understanding the inherent characteristics of a Goodyear welt.

The Initial Stiffness

The multiple layers of leather and the robust construction mean these shoes have a firmer feel out of the box. They require a break-in period during which the leather insole and cork filling mold to the specific shape of your foot.

Reduced Flexibility

Compared to cemented or athletic shoe constructions, a Goodyear welt is inherently more rigid. While this provides excellent support, it offers less "sneaker-like" flexibility, especially when brand new.

The Upfront Investment

This construction method is more labor-intensive and requires higher-quality materials. This is directly reflected in a higher initial purchase price compared to footwear made with less durable, glued construction.

Making the Right Choice for Your Goal

Your ideal shoe construction depends entirely on what you value most.

- If your primary focus is maximum lifespan and long-term value: A Goodyear-welted shoe is the definitive choice due to its unparalleled repairability.

- If your primary focus is demanding use and protection: The structural integrity and inherent water resistance of a Goodyear welt offer superior performance and durability.

- If your primary focus is immediate, out-of-the-box comfort: You might consider other constructions, but you must accept the significant compromise in longevity and repairability.

Ultimately, investing in Goodyear-welted footwear is acquiring a durable asset engineered to be maintained and worn for a lifetime.

Summary Table:

| Feature | Benefit |

|---|---|

| Two-Level Stitching | Creates a robust, layered bond between upper, insole, and outsole. |

| Easily Replaceable Soles | The welt allows for multiple resoles without damaging the shoe's core structure. |

| Superior Structural Integrity | Distributes stress evenly, resisting twisting and bending from daily wear. |

| Enhanced Water Resistance | The welt acts as a barrier, preventing water from seeping into the shoe. |

| Built-in Arch Support | Often includes a shank for stability, ensuring the shoe flexes correctly. |

Ready to Invest in Unmatched Durability?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality Goodyear-welted footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities ensure your customers receive footwear built to last for decades.

Let's build a durable future together.

Contact our team today to discuss your manufacturing needs and discover the 3515 advantage.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Is there a break-in period for Goodyear welt shoes? Why It's Key to a Custom Fit

- What is the historical significance of the Goodyear welt machine? Revolutionizing Durable Footwear Production

- What are the benefits of resoling dress shoes? Extend Life & Boost Comfort

- What is the overall importance of dress shoes? Build a Versatile, Confidence-Boosting Wardrobe

- What is the purpose of Cap Toe shoes? Combining Durability and Timeless Style

- What are the advantages of leather-soled shoes? Unlock Classic Elegance & Breathability

- How does the Goodyear Welted construction allow for sole replacement without damaging the upper? Discover the Secret to Long-Lasting Footwear

- How does the construction of Goodyear welted shoes contribute to their longevity? Built for Decades of Wear