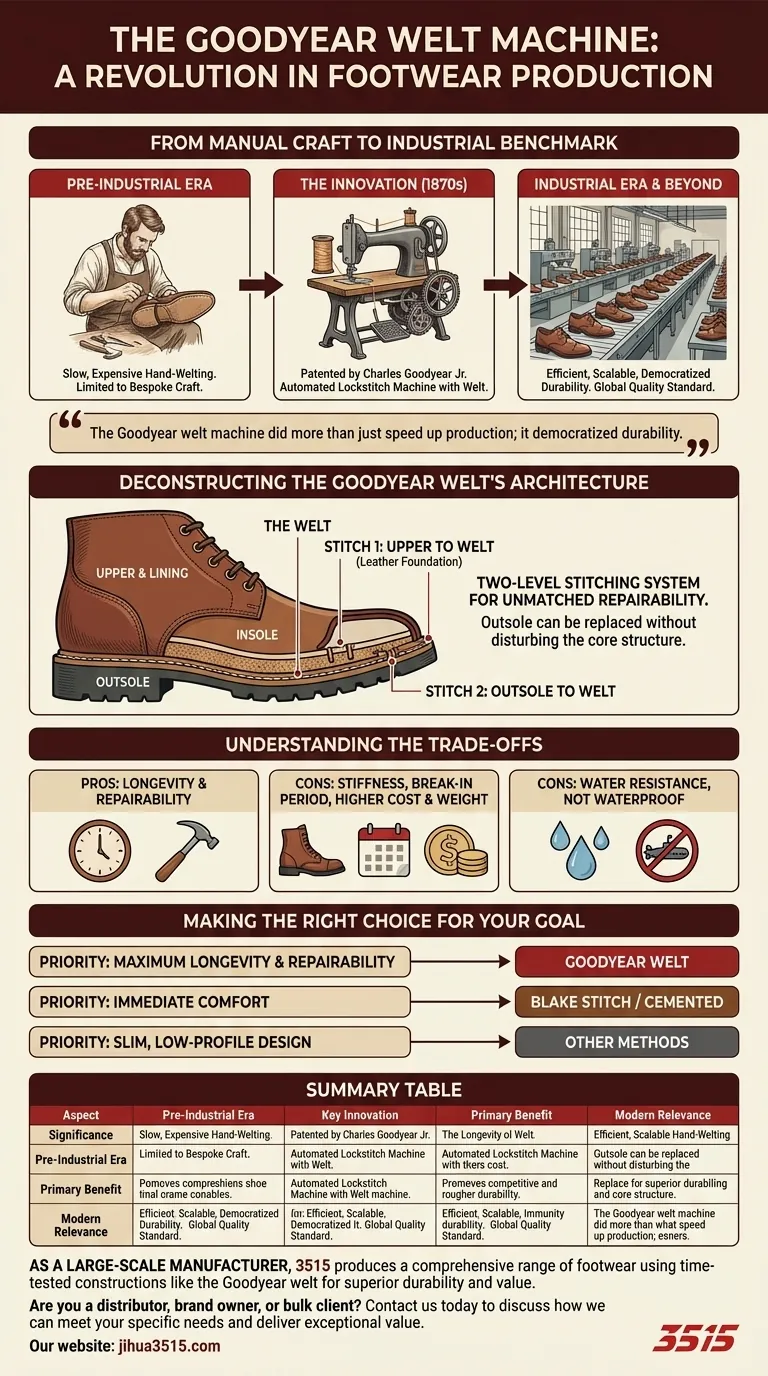

The historical significance of the Goodyear welt machine lies in its revolutionary ability to industrialize the production of durable, repairable footwear. Patented by Charles Goodyear Jr. in the 1870s, this machine replaced the slow, expensive process of hand-stitching, transforming high-quality shoemaking from a bespoke craft into an efficient, scalable industry and setting a new global standard for quality.

The Goodyear welt machine did more than just speed up production; it democratized durability. By creating a standardized method for attaching the sole, it made long-lasting, resoleable footwear accessible far beyond the world of bespoke, hand-stitched shoes.

From Manual Craft to Industrial Benchmark

The Challenge of Pre-Industrial Shoemaking

Before mechanization, creating a durable, repairable shoe required a highly skilled artisan to meticulously stitch every component by hand. This hand-welting process was incredibly time-consuming and expensive, limiting such footwear to a very small, wealthy clientele.

The Innovation of Charles Goodyear Jr.

The machine patented around 1875 didn't invent the concept of a welted shoe, but it perfected a way to execute it with mechanical speed and precision. It introduced a lockstitch sewing machine capable of attaching the shoe's upper to the sole using a leather strip, or welt.

The Impact on the Footwear Industry

This innovation was a catalyst for change. It enabled factories to mass-produce footwear with the same durability and repairability as their handmade counterparts. The Goodyear welt quickly became the benchmark for high-quality, long-lasting shoes and boots.

Deconstructing the Goodyear Welt's Architecture

The Welt: The Shoe's Foundation

The welt is a narrow strip of leather that runs along the perimeter of the outsole. Think of it as the foundational chassis of the shoe, connecting the upper (the part that covers your foot) to the sole (the part that hits the ground).

A Two-Level Stitching System

The genius of the Goodyear welt lies in its two independent stitches. The first stitch attaches the upper, the lining, and the insole to the welt. A second, separate stitch then attaches the outsole to the other side of the welt.

The Key to Unmatched Repairability

This two-part construction is the secret to the shoe's longevity. Because the outsole is stitched to the welt and not directly to the upper, a cobbler can easily cut the second stitch, remove the worn-out sole, and attach a new one without ever disturbing the shoe's core structure. This process can be repeated multiple times.

Understanding the Trade-offs

Initial Stiffness and Break-in Period

The multiple layers and robust construction of a Goodyear welted shoe often result in initial stiffness. These shoes typically require a break-in period for the leather and cork filler to mold to the wearer's foot.

Higher Cost and Weight

The process is more complex and uses more materials than cheaper, cemented (glued) constructions. This results in a higher initial purchase price and often a heavier, more substantial-feeling shoe.

Water Resistance, Not Waterproofing

While the construction is highly water-resistant, the stitching creates tiny holes through which water can eventually seep. It is not a truly waterproof construction compared to a sealed or specialized boot.

Making the Right Choice for Your Goal

When evaluating footwear, understanding this construction helps you align your purchase with your priorities.

- If your primary focus is maximum longevity and repairability: The Goodyear welt is the undisputed standard, offering the best long-term value through its ability to be resoled multiple times.

- If your primary focus is immediate, out-of-the-box comfort: A more flexible construction, like a Blake stitch or a cemented sole, may feel more comfortable initially with no break-in period.

- If your primary focus is a slim, low-profile design: The Goodyear welt's external welt and stitching create a slightly wider profile, whereas other methods can produce a more streamlined silhouette.

Ultimately, understanding the Goodyear welt is understanding a philosophy of quality—investing in an architecture built to last, not to be replaced.

Summary Table:

| Aspect | Significance |

|---|---|

| Pre-Industrial Era | Hand-welting was slow, expensive, and limited to bespoke crafts. |

| Key Innovation | Patented machine automated the welted construction process. |

| Primary Benefit | Democratized access to long-lasting, resoleable shoes and boots. |

| Modern Relevance | Remains the benchmark for quality, durable footwear construction. |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear using time-tested constructions like the Goodyear welt for superior durability and value.

Are you a distributor, brand owner, or bulk client seeking reliable, high-quality footwear? Our production capabilities encompass all types of durable shoes and boots built to last.

Contact us today to discuss how we can meet your specific needs and deliver exceptional value.

Visual Guide

Related Products

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How should new leather work boots be broken in? A Guide to Comfort and Durability

- Do heavy duty work boots stretch over time? The Truth About Fit & Break-In

- What makes work boots durable? The 3 Key Factors for Long-Lasting Footwear

- What is the complete process for deep cleaning leather work boots? A Step-by-Step Guide to Preserve Your Investment

- How can you identify high-quality boots? A Guide to Durable Materials and Construction