The construction of Goodyear welted shoes directly contributes to their longevity by creating a durable, multi-layered structure where the outsole is stitched to a separate leather strip (the welt), not directly to the shoe's upper. This clever design allows the sole—the part of the shoe that receives the most wear—to be completely replaced multiple times without ever compromising the integrity of the main body of the shoe.

The core principle behind the Goodyear welt's longevity is separation. By using the welt as an intermediary between the upper and the outsole, it turns the shoe's most common failure point—a worn-out sole—into a routine and repeatable repair, transforming the shoe into a long-term, maintainable asset.

Deconstructing the Goodyear Welt: A System Built to Last

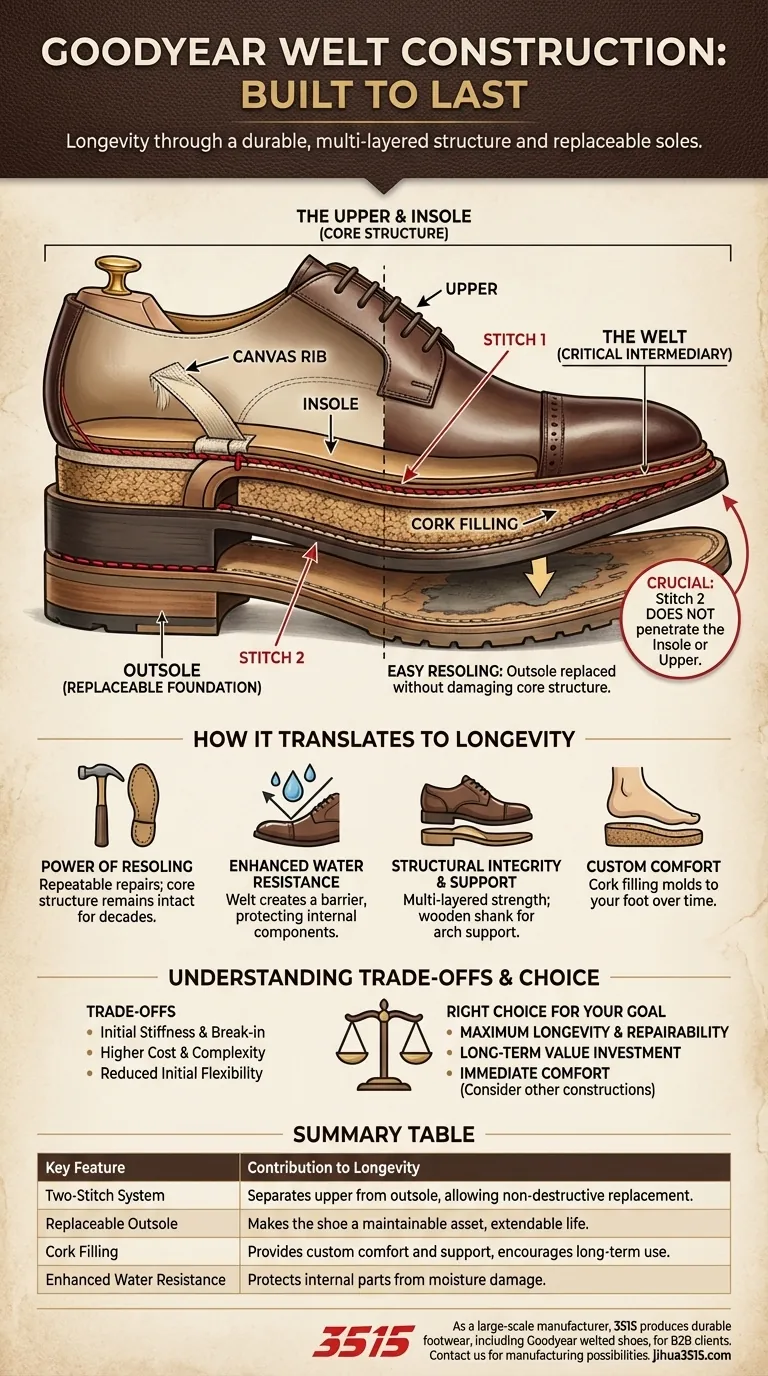

To understand why this method is so durable, it's essential to visualize its key components and how they are assembled. Unlike simpler constructions where the upper and sole are glued or stitched directly together, the Goodyear welt involves two independent, load-bearing stitches.

The Upper and Insole: The Core Structure

The process begins by stretching the shoe's upper over a form called a "last." A canvas rib is then attached to the insole, creating a secure anchor point for the first critical stitch. This forms the foundational structure of the shoe.

The Welt: The Critical Intermediary

A long, durable strip of leather known as the welt is then introduced. This piece is the heart of the system. It is stitched horizontally through the upper and into the canvas rib on the insole. This first stitch securely bonds the upper part of the shoe together into a single, robust unit.

The Outsole and Cork Filling: The Replaceable Foundation

With the welt attached, a cavity is formed between the insole and the outsole. This space is filled with cork, which provides cushioning and, over time, molds to the shape of your foot for a custom fit.

Finally, the outsole is attached. In the second, separate stitch, the outsole is sewn vertically to the welt. Crucially, this stitch does not penetrate the insole or the upper.

How This Construction Directly Translates to Longevity

The two-stitch system is not just a manufacturing detail; it is the primary reason these shoes can last for decades. Every element of the design prioritizes durability and repairability.

The Power of Resoling

Because the outsole is only attached to the welt, a cobbler can simply cut the second stitch, remove the worn-out sole and cork, and attach a new one. This process can be repeated numerous times without ever disturbing the stitch that holds the upper to the insole, preserving the shoe's core structure indefinitely.

Enhanced Water Resistance

The welt creates a more effective barrier around the edge of the shoe. This construction minimizes the chance of water penetrating the insole from the ground, protecting the shoe's internal components and keeping your foot dry.

Structural Integrity and Support

The multi-layered construction, often reinforced with a wooden shank in the arch, provides exceptional strength and foot protection. The cork footbed adds a layer of customized comfort and support that improves with wear, encouraging the long-term use the shoe is built for.

Understanding the Trade-offs

While renowned for durability, the Goodyear welt construction method involves clear trade-offs that are important to understand.

Initial Stiffness and Break-in

The robust, multi-layered build makes Goodyear welted shoes noticeably stiffer out of the box compared to more flexible constructions. They require a break-in period for the leather and cork to soften and conform to your foot.

Higher Cost and Complexity

Goodyear welting is a more complex, labor-intensive, and material-heavy process. This skilled craftsmanship is reflected in the higher initial purchase price of the footwear.

Reduced Initial Flexibility

Compared to a Blake-stitched shoe (where the sole is stitched directly to the insole) or a cemented shoe (where it is glued), a Goodyear welted shoe is inherently less flexible at first. This is a direct result of the durable, layered platform it's built upon.

Making the Right Choice for Your Goal

Understanding the principles of the Goodyear welt allows you to decide if it aligns with your priorities.

- If your primary focus is maximum longevity and repairability: The Goodyear welt is the definitive choice, offering a platform that can be maintained for decades with proper care.

- If your primary focus is a long-term value investment: These shoes represent a higher upfront cost that is offset over time by eliminating the need for frequent replacement.

- If your primary focus is immediate, out-of-the-box comfort and flexibility: You may prefer a different construction, but you will be sacrificing the unparalleled repairability that defines a Goodyear welt.

Ultimately, choosing a Goodyear welted shoe is an investment in a piece of footwear that is fundamentally built to be maintained, not discarded.

Summary Table:

| Key Feature | Contribution to Longevity |

|---|---|

| Two-Stitch System | Separates the upper from the outsole, allowing the sole to be replaced without damaging the shoe's core structure. |

| Replaceable Outsole | The worn-out sole can be stitched on and off the welt multiple times, making the shoe a maintainable asset. |

| Cork Filling | Molds to the foot for custom comfort and provides cushioning that supports long-term use. |

| Enhanced Water Resistance | The welt creates a barrier that protects internal components from moisture, prolonging the shoe's life. |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including time-tested constructions like the Goodyear welt. If you are looking for reliable, long-lasting footwear built for repeat business, let's discuss how we can support your brand's success.

Contact our team today to explore manufacturing possibilities.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- What should someone do if they are unsure about a company's dress code? Navigate with Confidence

- Is it acceptable to wear dress shoes with casual outfits? Elevate Your Smart Casual Office Style

- How can one balance a casual outfit when wearing dress shoes? Achieve a Polished Smart Casual Look

- Are brown dress shoes appropriate for formal events? A Guide to Choosing the Right Shoe

- Why is comfort important in dress shoes? Achieve All-Day Support for Professional Performance