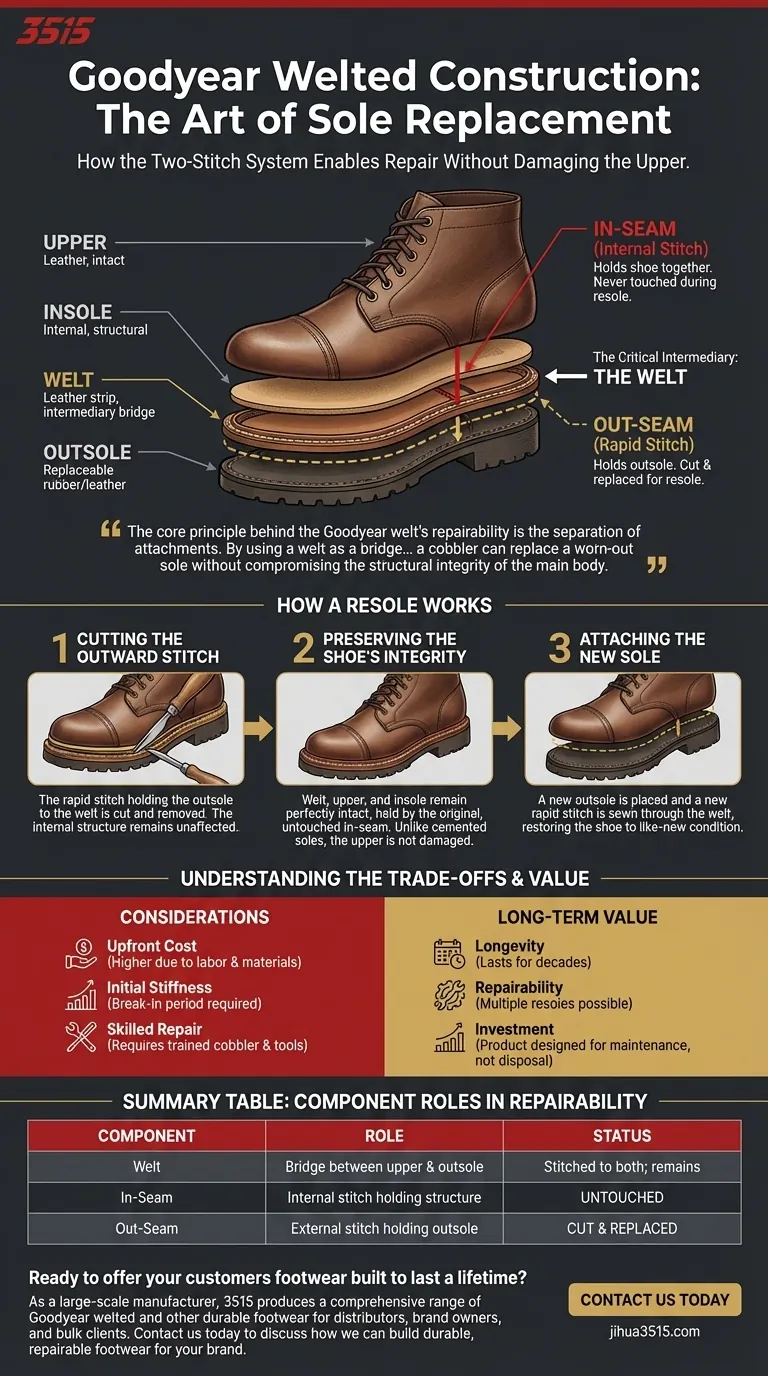

The short answer is that the Goodyear welt acts as a critical intermediary. The shoe's sole is not stitched directly to the upper leather. Instead, a separate strip of leather called a welt is attached to the upper, and the outsole is then stitched to that welt. This creates two independent stitches, allowing the sole to be removed and replaced by simply cutting the outer stitch without ever touching the one that holds the shoe together.

The core principle behind the Goodyear welt's repairability is the separation of attachments. By using a welt as a bridge between the upper and the outsole, a cobbler can replace a worn-out sole without compromising the structural integrity of the main body of the shoe.

The Anatomy of a Repairable Shoe

To understand how a sole can be replaced so cleanly, you must first understand the key components that make this construction method unique. It's a system where each part plays a specific role in creating a durable and serviceable foundation.

The Welt: The Critical Intermediary

The welt is the hero of this construction. It is a durable strip of leather that runs along the perimeter of the outsole.

During manufacturing, the welt is stitched to both the upper part of the shoe and the insole. This first, hidden stitch is what creates the shoe's core structure.

The Two-Stitch System

This process creates two primary, independent seams. The first is the in-seam, which attaches the insole, upper, and welt together. This stitch is internal and is never touched during a resole.

The second is the out-seam, or rapid stitch, which is visible on the bottom of the shoe. This is the stitch that attaches the outsole directly to the welt.

How a Resole Actually Works

The elegance of the Goodyear welt becomes apparent during the repair process. A skilled cobbler leverages the two-stitch system to perform a clean and effective replacement.

Step 1: Cutting the Outward Stitch

The process begins by carefully cutting and removing the rapid stitch that holds the worn-out outsole to the welt.

Because this stitch is completely separate from the one holding the upper, its removal has no impact on the rest of the shoe's structure.

Step 2: Preserving the Shoe's Integrity

With the old outsole removed, the welt, upper, and insole remain perfectly intact, held together by the original, untouched in-seam.

This is the fundamental difference from cheaper, cemented constructions where the sole is simply glued on. Tearing off a glued sole often damages the upper material, making a durable repair impossible.

Step 3: Attaching the New Sole

A new outsole is then placed onto the shoe and a new rapid stitch is sewn through the original holes in the welt.

This restores the shoe to a like-new condition from the sole down, ready for many more years of wear. The process can be repeated multiple times throughout the life of the shoe.

Understanding the Trade-offs

While renowned for its longevity, the Goodyear welt construction is not without its considerations. Objectivity requires acknowledging both its strengths and its initial drawbacks.

Upfront Cost

Goodyear welting is a more labor-intensive and material-heavy process. This results in a higher initial purchase price compared to shoes with cemented or Blake-stitched soles.

Initial Stiffness

The multiple layers—insole, cork filling, midsole, and outsole—can make the shoes feel stiff when brand new. They require a break-in period for the materials to mold to your foot.

The Need for Skilled Repair

While easily resolable, the process requires the tools and expertise of a trained cobbler. The cost of a resole is a fraction of a new pair, but it is an investment in maintenance.

Making the Right Choice for Your Goal

Ultimately, choosing a shoe construction method depends on your priorities. The Goodyear welt is an investment in a specific kind of ownership.

- If your primary focus is longevity and long-term value: The Goodyear welt is the definitive choice, as its repairability allows one pair of uppers to last for decades.

- If your primary focus is initial affordability and out-of-the-box flexibility: A cemented or Blake-stitched shoe may be a better fit, but you sacrifice the ability to perform durable, repeated repairs.

Choosing a Goodyear welted shoe is an investment in a product designed not to be disposable, but to be maintained.

Summary Table:

| Component | Role in Repairability |

|---|---|

| Welt | A leather strip that acts as a bridge; stitched to the upper and insole. |

| In-Seam | The internal stitch holding the upper, insole, and welt together; remains untouched during a resole. |

| Out-Seam | The visible stitch attaching the outsole to the welt; this is the only stitch cut and replaced. |

Ready to offer your customers footwear built to last a lifetime?

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted and other durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots designed for longevity and easy repair, ensuring your customers keep coming back.

Contact us today to discuss how we can build durable, repairable footwear for your brand.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- What are the main benefits of Goodyear welt construction? Unlock Decades of Durability & Value

- What should be the overall approach to selecting professional dress shoes? Invest in Quality, Fit, and Timeless Style

- What other styles of men's dress shoes exist? Discover Niche Styles for Every Occasion

- What is the function of superior customer experience for dress and formal shoes? Build Loyalty with Service Excellence

- What is the heel of a dress shoe and what additional features might it have? Discover the Markers of Quality Craftsmanship

- What is Goodyear welted construction and who invented it? A Guide to Unmatched Durability

- How does the specific leather molding process simulate comfort in postmodern footwear design? Achieve Luxury Aesthetics

- What occasions are appropriate for wearing dress shoes with jeans? A Guide to Smart-Casual Style