At its core, the Goodyear welt process differs from other methods by using a separate strip of leather—the welt—to connect the shoe's upper to its outsole. This creates a two-level stitching system that makes the shoe exceptionally durable, water-resistant, and easy to resole multiple times. Methods like Blake stitching or cementing attach the sole more directly, trading this robust construction for flexibility or lower cost.

The fundamental difference is one of architecture. Goodyear welting builds a durable, repairable foundation by using the welt as an intermediary, while other methods create a simpler, more direct connection between the shoe's main components.

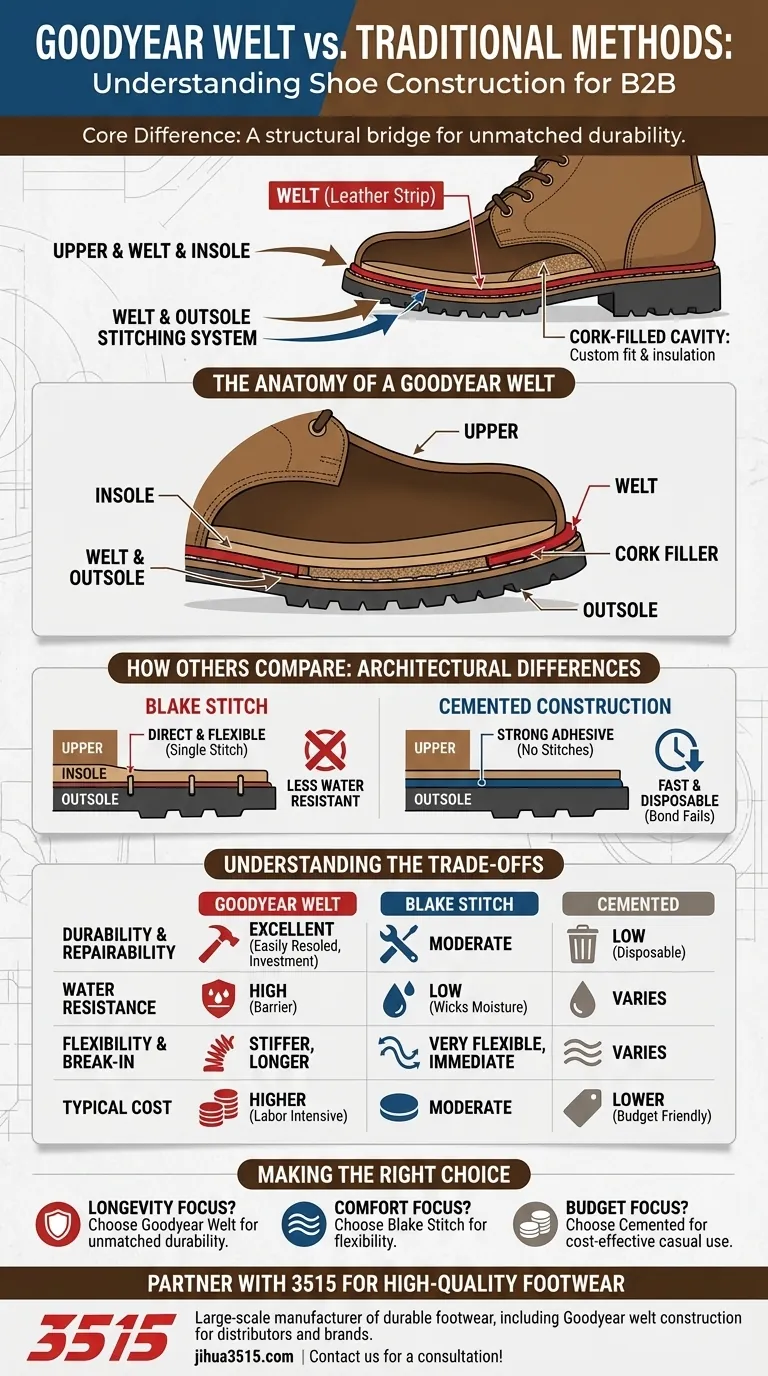

The Anatomy of a Goodyear Welt

To understand the difference, you must first understand the components that make this construction method unique. It's a system designed for longevity from the ground up.

The Critical Component: The Welt

The welt is a dedicated strip of leather that runs along the perimeter of the outsole. Think of it as a structural bridge.

Its sole purpose is to serve as the connection point for both the upper part of the shoe and the outsole, without either being directly attached to the other.

The Two-Level Stitching System

The Goodyear welt process is defined by two independent machine stitches.

First, the upper is sewn to the welt and the insole. Then, in a separate step, the welt is sewn to the outsole. This separation is the key to its celebrated repairability.

The Cork-Filled Cavity

The construction creates a cavity between the insole and the outsole. This space is filled with a layer of cork.

Over time, the cork filling compresses and molds to the shape of your foot, creating a custom-like fit. It also provides excellent insulation and cushioning.

How Other Construction Methods Compare

The Goodyear welt's advantages become clear when contrasted with the two other common methods. Each serves a different purpose and delivers a different result.

Blake Stitch: Direct and Flexible

In a Blake stitch construction, a single stitch runs directly from the outsole, through the insole, and into the shoe's upper.

This creates a more flexible shoe with a closer-cut, sleeker profile. However, it compromises water resistance, as moisture can wick up through the stitch into the shoe's interior.

Cemented Construction: Fast and Disposable

This is the most common method for mass-market footwear. The outsole is simply attached to the upper using a strong adhesive.

Cementing is fast and inexpensive, but it is the least durable option. The bond can fail over time, and these shoes typically cannot be resoled.

Understanding the Trade-offs

Choosing a shoe construction method is about balancing competing priorities. There is no single "best" method, only the best method for a specific goal.

Durability and Repairability

The Goodyear welt is unmatched here. Because the outsole is stitched to the welt and not the upper, a cobbler can easily cut the old stitch and attach a new sole without compromising the shoe's structure.

This is why Goodyear-welted shoes are often seen as a long-term investment.

Flexibility and Break-in Period

The complex layers and robust materials make Goodyear-welted shoes stiffer out of the box. They require a significant break-in period.

Blake-stitched shoes, with their simpler internal construction, are far more flexible and comfortable from the very first wear.

Water Resistance

The welt provides a superior barrier against water intrusion compared to a Blake stitch. While not fully waterproof, it offers significantly more protection for daily wear in wet conditions.

Cost and Production

The Goodyear welt process is more labor-intensive and requires more materials, making the final product more expensive.

Cemented and Blake-stitched shoes are simpler and faster to produce, which is reflected in their lower price points.

Making the Right Choice for Your Footwear

Your decision should be guided by what you value most in a shoe.

- If your primary focus is longevity and long-term value: A Goodyear-welted shoe is the definitive choice for its unmatched durability and repairability.

- If your primary focus is immediate comfort and a sleek profile: A Blake-stitched shoe offers superior flexibility and a closer-cut aesthetic.

- If your primary focus is budget for casual or occasional use: A cemented shoe provides a cost-effective solution that serves its purpose well.

Understanding these construction methods empowers you to invest in footwear that truly aligns with your needs.

Summary Table:

| Feature | Goodyear Welt | Blake Stitch | Cemented |

|---|---|---|---|

| Durability & Repairability | Excellent (Easily Resoled) | Moderate | Low (Often Disposable) |

| Water Resistance | High | Low | Varies |

| Flexibility & Break-in | Stiffer, Longer Break-in | Very Flexible, Immediate Comfort | Varies |

| Typical Cost | Higher (Investment) | Moderate | Lower (Budget) |

Ready to Source Durable, High-Quality Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, including those built with robust construction methods like the Goodyear welt.

Partner with us to provide your customers with long-lasting value. Let's discuss your specific needs and how we can deliver the quality and reliability your brand demands.

Contact our team today for a consultation!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management