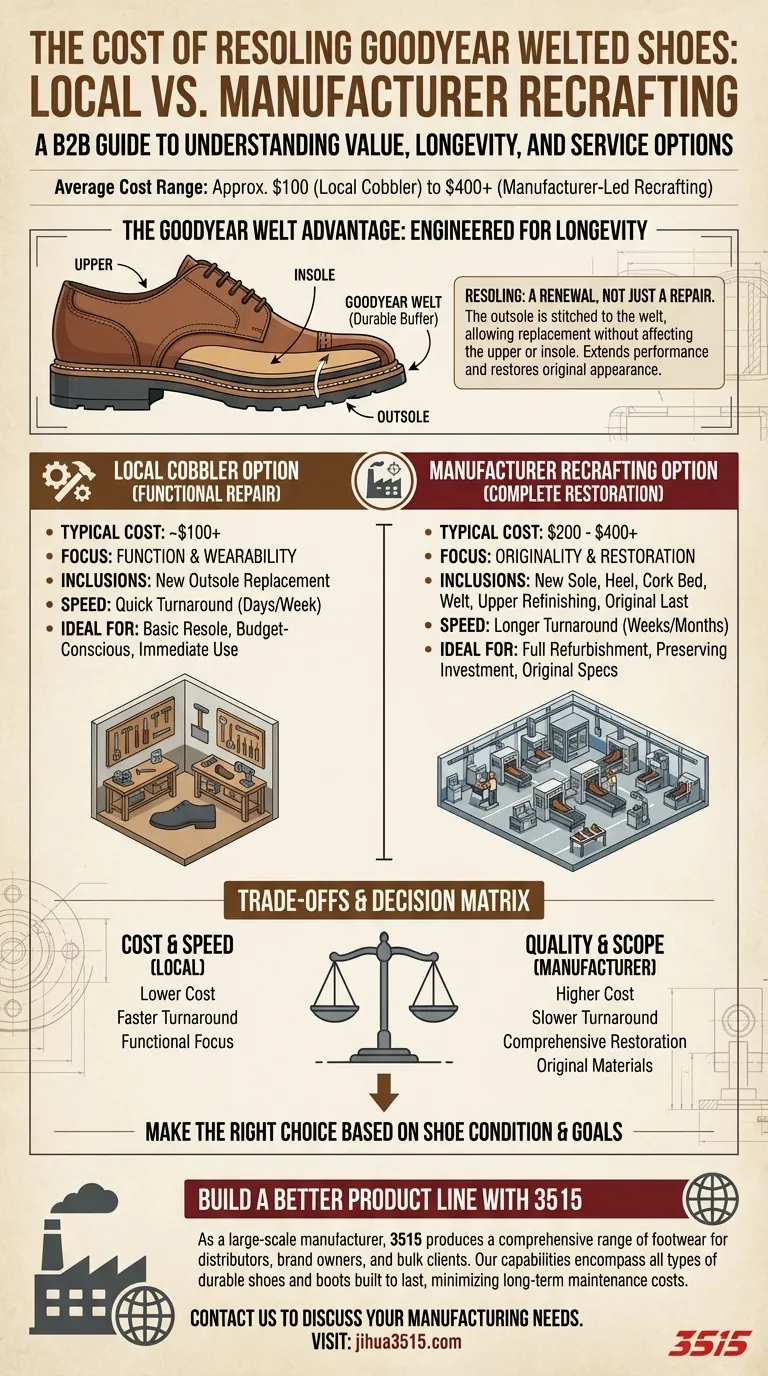

On average, the cost to resole Goodyear welted shoes typically ranges from around $100 for a local cobbler to over $400 for a manufacturer-led recrafting service. The final price is determined not just by the new sole, but by the comprehensiveness of the service—whether you are seeking a functional repair or a complete factory restoration.

The cost of resoling is a direct reflection of the service level chosen. Understanding the difference between a local repair and a full manufacturer recrafting is essential to managing the long-term value of your footwear investment.

Why Resoling is Fundamental to Goodyear Welted Shoes

Goodyear welted shoes are specifically engineered for longevity and repair. The ability to resole them isn't an afterthought; it's a core feature of their design and a primary reason for their higher initial cost.

The Role of the Welt

The Goodyear welt is a strip of leather that runs along the perimeter of the outsole. It acts as a durable buffer between the insole (where your foot rests) and the outsole (which contacts the ground).

During a resole, a cobbler cuts the stitching that attaches the outsole to the welt, leaving the insole and upper completely intact. A new outsole is then stitched onto the original welt.

More Than a Repair, It's a Renewal

Resoling is a form of preventative maintenance. It refreshes the shoe's foundation, extends its performance, and restores its original appearance.

This process leverages the shoe's inherent repairability, allowing the durable leather uppers to outlast multiple soles and deliver decades of service.

Deconstructing the Cost: What Are You Paying For?

The wide price range for resoling stems from two distinct service philosophies. Your choice depends on your budget, timeline, and desired outcome.

The Local Cobbler Option (Approx. $100)

This is the most common and cost-effective path. A local cobbler will remove the worn-out outsole and attach a new one.

This service is typically focused on function—replacing the sole to make the shoe wearable again. The quality of materials and craftsmanship can vary, so choosing a reputable professional is key.

The Manufacturer Recrafting Option (Up to $400+)

Sending your shoes back to the original manufacturer is a far more comprehensive process. This is less of a repair and more of a complete restoration.

In addition to replacing the outsole, a recrafting service often includes replacing the cork footbed, the heel, and sometimes the welt itself. The shoe is put back on its original last (the form it was built on) to restore its shape, and the uppers are often cleaned and refinished.

Understanding the Trade-offs

Choosing between a local cobbler and a manufacturer service involves balancing cost against the scope and quality of the work.

Cost vs. Originality

A local cobbler provides a functional repair at a lower price point. However, a manufacturer's service uses the exact original materials, specifications, and lasts, ensuring the shoe is restored as closely as possible to its factory-new condition.

Speed vs. Turnaround Time

Your local shoe repair shop can often complete a resole in a matter of days or a week. A full recrafting service from a manufacturer can take several weeks or even months due to shipping and production queues.

Basic Repair vs. Full Refurbishment

Assess the overall condition of your shoes. If only the outsole is worn, a local cobbler is an excellent choice. If the heel is collapsing, the cork bed has compressed, and the uppers need care, a full recrafting addresses all these issues at once.

Making the Right Choice for Your Shoes

Your decision should be guided by the condition of your shoes and your goal for the repair.

- If your primary focus is a quick, functional repair: A reputable local cobbler is your most efficient and cost-effective choice.

- If your primary focus is restoring the shoe to its original specifications: Sending it back to the manufacturer for a full recrafting is the best way to preserve your investment.

- If your primary focus is balancing cost and quality: Seek a high-end, specialized cobbler who can offer more than a basic resole without the full manufacturer price tag.

By understanding these options, you can confidently maintain your Goodyear welted shoes for a lifetime of wear.

Summary Table:

| Service Level | Typical Cost | Key Inclusions | Ideal For |

|---|---|---|---|

| Local Cobbler | ~$100+ | New outsole replacement | Quick, functional repair |

| Manufacturer Recrafting | $200 - $400+ | New sole, heel, cork bed, welt, and upper refinishing | Full restoration to original specs |

Need Durable, High-Quality Footwear Designed for Long-Term Value?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots built to last, minimizing long-term maintenance costs.

Let us help you build a better product line. Contact our team today to discuss your manufacturing needs and how our expertise can benefit your business.

Visual Guide

Related Products

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- What is classified as a dress shoe? A Guide to Formal Footwear Styles & Selection

- What makes Wingtips unique among dress shoes? Discover the Perfect Blend of Style and Versatility

- What are the benefits of hidden seams in Goodyear Welted shoes? Superior Durability & Refined Style

- What is the historical significance of the Goodyear welt machine? Revolutionizing Durable Footwear Production

- What are some quick tips for achieving a mirror shine on dress shoes? Speed Up Your Shine with Pro Hacks

- What are the main reasons why men's dress shoes are often uncomfortable? Unpacking the Style vs. Comfort Trade-Off

- How does Goodyear Welted construction contribute to sustainability? Unlock Decades of Wear with Repairable Design

- What are some style ideas for pairing men's lace-up boots with outfits? Master Formality & Aesthetic