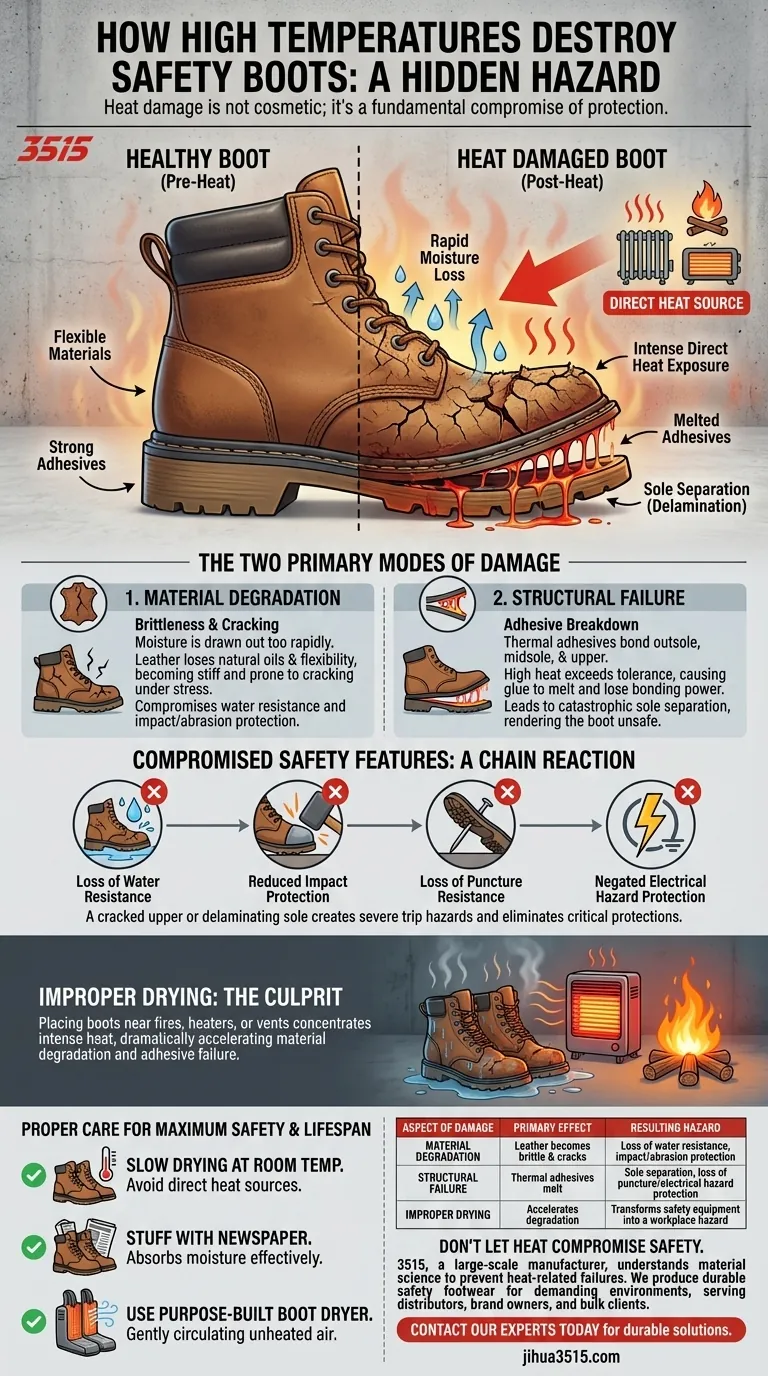

Ultimately, high temperatures destroy safety boots by attacking their two most critical elements: the physical materials and the adhesives that hold them together. Repeated exposure to direct heat sources causes the upper materials, like leather, to become brittle and crack while simultaneously melting the glues that bond the sole to the boot, leading to catastrophic structural failure.

Heat damage is not a cosmetic issue; it is a fundamental compromise of a boot's protective capabilities. By weakening the materials and construction, heat silently transforms a critical piece of safety equipment into a potential hazard.

The Two Primary Modes of Heat Damage

High heat initiates a two-pronged attack on your footwear. It degrades the materials themselves and breaks down the bonds holding the boot's structure together.

Material Degradation: Brittleness and Cracking

When materials like leather are exposed to intense, direct heat, the moisture within them is drawn out too rapidly. This process strips the material of its natural oils and flexibility.

The result is a brittle, stiff upper that is prone to cracking with the normal stress of walking. These cracks compromise the boot's integrity, eliminating its water resistance and weakening its ability to protect you from impacts or abrasions.

Structural Failure: Adhesive Breakdown

Modern safety boots rely on powerful thermal adhesives to bond the outsole, midsole, and upper into a single, durable unit. These glues are designed for strength but have a specific temperature tolerance.

Exposing boots to a direct heat source, such as a radiator or campfire, can easily exceed this tolerance. The glue melts and loses its bonding power, causing the layers to separate, a process known as delamination. A separated sole is a critical failure that renders the boot unsafe and unusable.

Understanding the Hidden Dangers

The damage from heat is often more severe than it appears on the surface. What looks like a minor crack or a slightly peeling sole can signify a deep, irreversible loss of a boot's safety functions.

Compromised Safety Features

A boot is a system of protective features. Heat damage creates a chain reaction of failure. A cracked upper no longer protects against chemical splashes. A delaminating sole eliminates puncture resistance, negates electrical hazard protection, and creates a severe trip hazard.

The Problem with Direct Heat Drying

The most common cause of this damage is improper drying. After a day in wet conditions, the temptation to place boots next to a fire, heater, or vent is strong.

This practice concentrates intense heat on one area of the boot, dramatically accelerating material degradation and adhesive failure. The boot is not designed to withstand this type of localized, high-temperature exposure.

How to Properly Care for Your Boots

Proper drying and maintenance are not about preserving the look of your boots; they are about ensuring they can protect you when it matters most.

- If your primary focus is maximizing safety and lifespan: Always dry wet boots slowly at room temperature. Remove insoles, stuff the boots with newspaper to absorb moisture, and consider using a purpose-built boot dryer that uses gently circulating, unheated air.

- If your primary focus is recovering from wet conditions quickly: Resist the urge to use direct heat. Swapping out saturated newspaper every few hours is the most effective and safest way to speed up the process without causing damage.

Ultimately, treating your safety boots with care is a direct investment in your own well-being on the job.

Summary Table:

| Aspect of Damage | Primary Effect | Resulting Hazard |

|---|---|---|

| Material Degradation | Leather becomes brittle and cracks | Loss of water resistance, impact/abrasion protection |

| Structural Failure | Thermal adhesives melt, causing delamination | Sole separation, loss of puncture/electrical hazard protection |

| Improper Drying | Accelerates degradation and adhesive failure | Transforms safety equipment into a workplace hazard |

Don't let heat compromise your team's safety and your equipment budget.

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear designed for durability in demanding environments. We understand the critical importance of material science and construction in preventing heat-related failures.

Our production capabilities encompass all types of safety shoes and boots for distributors, brand owners, and bulk clients, ensuring your workforce has reliable protection.

Contact our experts today to discuss durable safety footwear solutions that protect your workers and your investment.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What are the advantages of rubber soles for work boots? Unbeatable Grip & Durability

- What are the core safety features of industrial safety shoes? Expert Guide for Bridge & Heavy Machinery Safety

- What are the requirements for oilfield boots? Essential Safety & Durability Features

- What are some hazards that can cause slips and falls in the workplace? Prevent Costly Injuries & Boost Safety

- What is the difference between side-zip and lace-up security guard safety boots? Speed vs. Perfect Fit