The single most critical requirement for oilfield boots is a certified safety toe cap to protect against severe impact and compression injuries. Due to the constant presence of heavy machinery, falling tools, and other industrial hazards, footwear must meet specific safety standards, with steel, composite, or aluminum toes all being common and approved options.

The core purpose of an oilfield boot is not just to be durable footwear, but to function as a critical piece of Personal Protective Equipment (PPE). The right boot is a system designed to mitigate multiple, simultaneous risks inherent to the oil and gas industry, from crush injuries to hazardous chemical exposure.

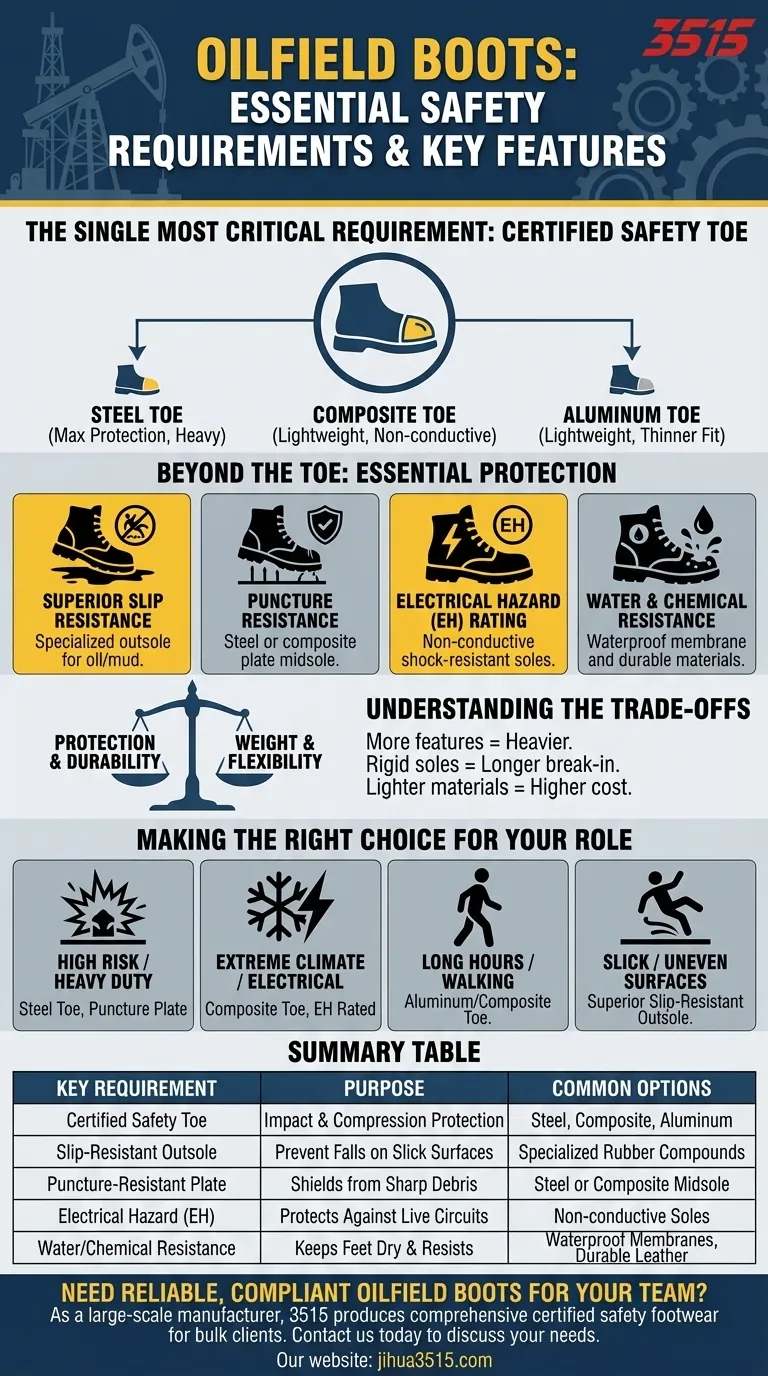

The Core Requirement: Certified Impact Protection

The defining feature of any oilfield boot is its ability to protect your feet from being crushed. This is why a certified safety toe is the first and most important requirement.

Why Safety Toes are Non-Negotiable

Oil rigs and drilling sites are dynamic environments with a high risk of heavy or sharp objects falling or rolling onto the foot. A standard boot offers no meaningful protection against this threat.

Safety toes are specifically engineered and tested to withstand significant force, preventing catastrophic injury from heavy equipment, pipes, or tools.

Steel vs. Composite vs. Aluminum Toes

All three primary types are approved by the Occupational Safety and Health Administration (OSHA) and provide certified protection.

- Steel Toes: The traditional standard, offering maximum protection against impact. They are often the most cost-effective but can be heavy and conduct heat and cold.

- Composite Toes: Made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter than steel, do not conduct electricity or temperature, and won't set off metal detectors.

- Aluminum Toes: Offer a lightweight alternative to steel while still meeting the same safety standards. They are typically thinner than composite toes, providing a less bulky fit.

Beyond the Toe: Essential Features for the Oilfield

While the safety toe is mandatory, the harsh environment of an oilfield demands several other critical protective features. A truly compliant and effective boot will incorporate most, if not all, of the following.

Superior Slip Resistance

Oilfield surfaces are notoriously slick with a constant presence of oil, drilling mud, water, and grease on metal decking. A boot's outsole must be made from a specialized rubber compound designed for oil and slip resistance to prevent dangerous falls.

Puncture Resistance

The ground is often littered with sharp metal debris, nails, and other hazards that can easily penetrate a standard sole. Many oilfield boots include a puncture-resistant plate—made of steel or a flexible composite material—mid-soled to protect the underside of the foot.

Electrical Hazard (EH) Rating

Accidental contact with live electrical circuits is a serious risk. Boots with an EH rating are constructed with non-conductive, shock-resistant soles and heels, providing a crucial secondary source of protection.

Water and Chemical Resistance

Workers are constantly exposed to water, mud, drilling fluids, and other chemicals. A boot with a waterproof membrane is essential for keeping feet dry, while the leather and sole materials must be durable enough to resist degradation from exposure to oil and chemicals.

Understanding the Trade-offs

Choosing the right boot involves balancing competing factors. Understanding these trade-offs is key to selecting footwear that is both safe and functional for long shifts.

Protection vs. Weight

Generally, boots with more protective features, like steel toes and puncture plates, are heavier. This added weight can increase fatigue over a 12-hour shift. Lighter composite materials can reduce this strain but may come at a higher cost.

Durability vs. Flexibility

The most durable boots are often made with thick leather and rigid soles that provide excellent support and longevity. However, this rigidity often requires a significant break-in period and can feel restrictive compared to more flexible designs.

Site-Specific Requirements

While these features represent the industry standard, always remember that the ultimate authority is the safety manager for your specific company or worksite. They may require a particular type of boot, such as a metatarsal guard for added top-of-foot protection.

Making the Right Choice for Your Role

Your specific job and environment should guide your final decision. Use these points to prioritize what matters most for your safety and comfort.

- If your primary focus is maximum impact protection in a high-risk area: A classic steel-toe boot with a puncture-resistant plate is the proven choice.

- If you work in extreme cold or heat, or around electrical hazards: A composite-toe boot with an EH rating offers superior thermal insulation and safety.

- If your role involves constant walking and long hours on your feet: Prioritize a lighter aluminum or composite-toe boot to minimize fatigue without sacrificing protection.

- If you consistently work on slick, uneven, or debris-filled surfaces: The quality and tread of the oil-and-slip-resistant outsole should be your top priority.

Ultimately, selecting the correct oilfield boot is a critical investment in your personal safety and daily well-being on the job.

Summary Table:

| Key Requirement | Purpose | Common Options |

|---|---|---|

| Certified Safety Toe | Protects against impact & compression | Steel, Composite, Aluminum |

| Slip-Resistant Outsole | Prevents falls on slick, oily surfaces | Specialized rubber compounds |

| Puncture-Resistant Plate | Shields foot from sharp debris | Steel or composite midsole |

| Electrical Hazard (EH) Rating | Protects against live circuits | Non-conductive soles & heels |

| Water/Chemical Resistance | Keeps feet dry, resists degradation | Waterproof membranes, durable leather |

Need Reliable, Compliant Oilfield Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial boots, including oilfield-specific models with the essential safety features outlined above.

We can provide durable, compliant footwear that meets the rigorous demands of the oil and gas industry, ensuring your workforce is protected. Contact us today to discuss your bulk footwear needs and request a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What do the symbols on safety footwear indicate? A Guide to Decoding Boot Safety Ratings

- What safety boots are recommended for the oil and gas industry? Essential Features for Hazardous Sites

- What specific protective features are required for safety shoes in high-temperature rotary kiln maintenance areas?

- Why is choosing the right work footwear important? Essential for Safety, Health & Productivity