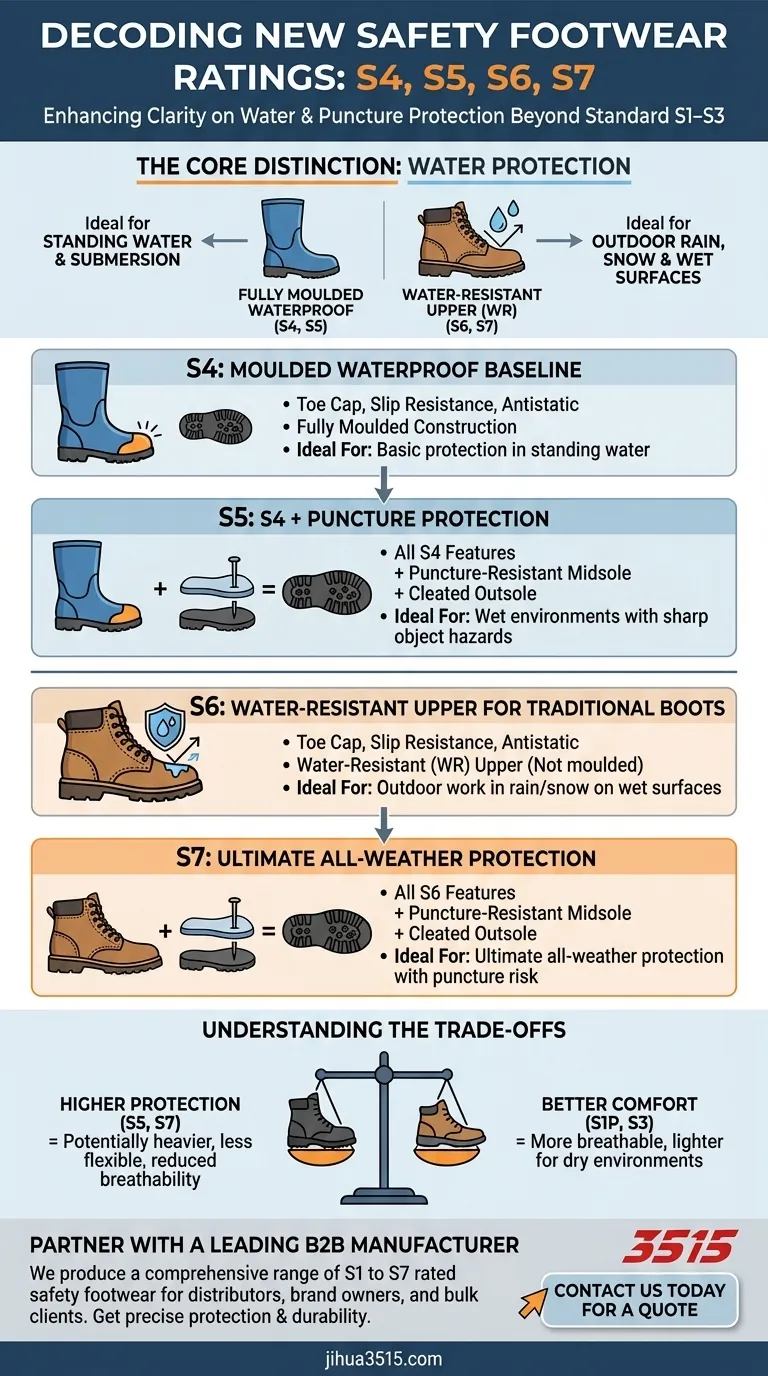

To enhance clarity and address modern workplace hazards, the safety footwear standards introduced four key protection levels beyond the traditional S1-S3 ratings. These are S4, S5, S6, and S7, which are built upon a foundation of water protection and electrical resistance, with added features for puncture protection and water resistance of the upper material.

The new safety ratings, particularly S6 and S7, were created to explicitly define footwear with water-resistant uppers, distinguishing them from the fully moulded waterproof boots classified as S4 and S5. This change allows you to select protection based not just on impact and puncture risk, but also on the specific type of water exposure in your environment.

A New Framework for Workplace Safety

To understand the new ratings, it's essential to grasp the core distinction they were designed to address: the difference between a fully waterproof boot and a boot with a water-resistant upper.

The Foundation: S4 and S5 Ratings

The newer ratings begin with S4 as the baseline. An S4-rated boot provides a protective toe cap, slip resistance, and antistatic properties.

Its defining feature is that it's typically a fully moulded polymer or rubber boot (like a Wellington), making it completely waterproof.

The S5 rating includes all the features of S4 but adds a penetration-resistant midsole and a cleated outsole for superior grip.

The Key Differentiator: Water Resistance (WR)

The most significant change in the standard is the formal introduction of a specific test for water resistance (WR) for the boot's upper material.

This created a parallel track for traditional, non-moulded safety boots, leading to the creation of the S6 and S7 categories.

Decoding the New S-Ratings: S4 to S7

Each new level builds upon the last, creating a clear hierarchy of protection against specific environmental hazards.

S4: Baseline for Moulded Waterproof Footwear

S4 includes a toe cap, slip resistance, and antistatic properties. Its one-piece moulded construction makes it the standard for basic waterproof protection where there is no puncture risk.

S5: S4 Plus Puncture Protection

S5 is the highest level for fully moulded waterproof footwear. It adds a puncture-resistant midsole and a cleated outsole to the S4 foundation, making it ideal for wet environments with sharp-object hazards.

S6: Water Resistance for Traditional Boots

S6 builds on the same foundational protections as S4 (toe cap, slip resistance) but adds a specific rating for water resistance (WR) on the boot's upper. This applies to boots that are not fully moulded but whose materials and construction are designed to keep water out.

S7: The Ultimate All-Weather Protection

S7 is the new pinnacle of protection for non-moulded footwear. It combines all the features of S6, including the water-resistant upper, with the puncture-resistant midsole and cleated outsole found in the S5 rating.

Understanding the Trade-offs

Choosing the highest rating is not always the best strategy. The right choice depends on balancing protection with comfort and the specific demands of the job.

Why Not Always Choose S7?

Higher-rated boots, especially S5 and S7 with their protective midsoles, can be heavier and less flexible. This can lead to fatigue over a long workday.

Furthermore, the focus on water resistance in S6 and S7 might mean reduced breathability compared to S1-S3 boots designed for dry, indoor environments.

The Importance of Additional Markings

The S-rating provides the overall classification, but it's not the whole story. S5 and S7 ratings inherently require puncture protection, and additional markings often clarify the type of protection used.

Codes like P, PL, or PS can indicate whether the puncture-resistant insert is made of steel or a non-metallic composite material, which can affect the boot's weight and flexibility.

Making the Right Choice for Your Environment

Your selection should be a direct response to the hazards you face daily.

- If your primary focus is working in standing water or very wet conditions: Choose S4 for basic protection or S5 if there is a risk of sharp objects underfoot from submersion.

- If your primary focus is working outdoors in rain, snow, or on wet surfaces: Choose S6 for excellent water resistance with more breathability, or S7 for the same protection plus a puncture-resistant sole.

- If your primary focus is dry work with impact or compression risks: The traditional S1P or S3 ratings may still be perfectly suitable and offer better breathability for all-day comfort.

By understanding that the new ratings clarify the type and level of water protection, you can choose footwear that provides precise, effective safety without compromise.

Summary Table:

| Rating | Key Features | Ideal For |

|---|---|---|

| S4 | Toe cap, slip resistance, antistatic, fully waterproof (moulded) | Basic protection in standing water |

| S5 | All S4 features + puncture-resistant midsole, cleated outsole | Wet environments with sharp object hazards |

| S6 | Toe cap, slip resistance, antistatic, water-resistant (WR) upper | Outdoor work in rain/snow on wet surfaces |

| S7 | All S6 features + puncture-resistant midsole, cleated outsole | Ultimate all-weather protection with puncture risk |

Need the Right Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of S1 to S7 rated safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the precise protection, comfort, and durability your workforce needs.

Let us help you equip your team with the right safety solution.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How do some boots combine materials for better performance? Achieve Superior Safety & Comfort

- What are the core safety features of industrial safety shoes? Expert Guide for Bridge & Heavy Machinery Safety

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What does CE-approval indicate for safety boots? Your Guide to EU-Compliant Footwear Protection

- What is the difference between side-zip and lace-up security guard safety boots? Speed vs. Perfect Fit