The primary features that make oilfield safety shoes resistant to heat and flames are the specialized materials used in their construction. These are not standard leathers or plastics, but rather advanced composites and treated fabrics engineered to withstand extreme temperatures without igniting, melting, or rapidly degrading, thereby forming a critical barrier between the worker and the thermal hazard.

The resistance of a safety shoe to heat and flames is not a single component, but a system. It relies on a combination of a heat-resistant upper, a high-temperature outsole, and even flame-retardant stitching to ensure the boot maintains its structural integrity when it matters most.

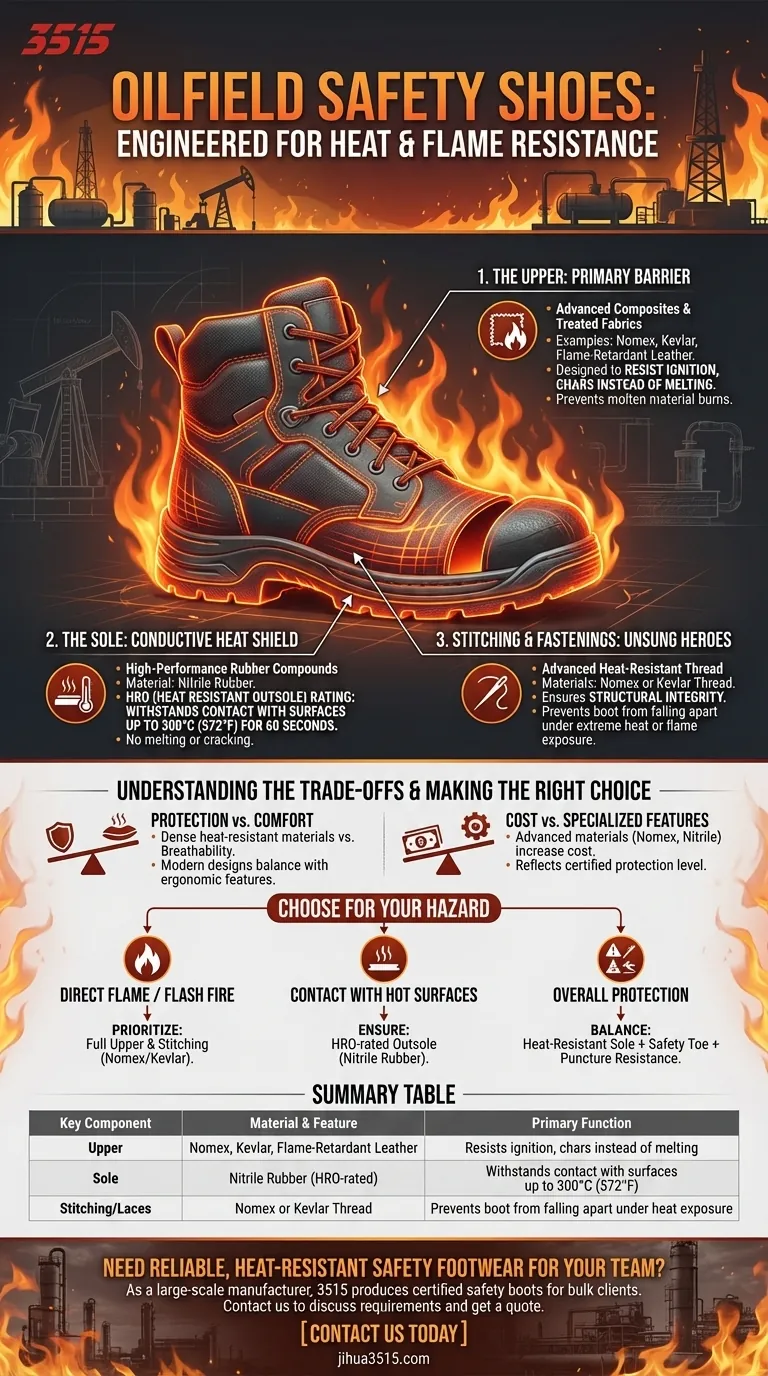

The Anatomy of a Heat-Resistant Boot

To understand this protection, you must look at the key components of the shoe, as each plays a distinct role in shielding the wearer from thermal threats common in oilfield environments.

The Upper: Your First Line of Defense

The "upper" is the main body of the shoe that covers your foot. In heat-resistant models, this is made from materials specifically chosen for their poor thermal conductivity and high ignition point. Common choices include specially treated, flame-retardant leather or synthetic fabrics like Nomex and Kevlar. These materials are designed to resist catching fire and will often char rather than melt, preventing molten material from causing severe burns.

The Sole: Resisting Conductive Heat

Oilfield workers often walk on surfaces that are extremely hot, such as metal decking or superheated ground. The outsole must protect against this conductive heat transfer.

High-performance safety shoes use outsoles made from specific rubber compounds, most commonly Nitrile rubber. These soles are often certified with an HRO (Heat Resistant Outsole) rating, which means they can withstand contact with a 300°C (572°F) surface for 60 seconds without melting or cracking.

Stitching and Fastenings: The Unsung Heroes

A boot is only as strong as its weakest point. Standard polyester or nylon threads and laces can melt at relatively low temperatures, causing the boot to literally fall apart during a critical incident.

To prevent this, true heat and flame-resistant footwear uses stitching and laces made from the same advanced materials as the upper, such as Nomex or Kevlar thread. This ensures the entire structure of the boot remains intact during short-term exposure to flame or extreme heat.

Understanding the Trade-offs

Selecting the right boot involves balancing heat resistance with other critical needs. Understanding the inherent compromises is key to making an informed decision.

Protection vs. Comfort

Materials that are excellent at resisting heat are often dense and less breathable than standard materials. While features like cushioned insoles and ergonomic designs enhance comfort, there can be a trade-off between maximum thermal protection and all-day breathability.

Specialized Features and Cost

Advanced materials like Nomex and specialized Nitrile compounds are more expensive to produce. The cost of a safety shoe often reflects the level and type of certified protection it offers. A boot designed for intermittent radiant heat will have a different construction and price point than one designed for direct flame contact.

The Importance of Multiple Safety Features

In an oilfield, heat is just one of many hazards. A boot must also provide protection against impact, compression, punctures, and slips. Materials like Kevlar, for example, are often used in puncture-resistant midsoles but also happen to offer excellent heat resistance, providing dual benefits.

Making the Right Choice for Your Hazard

Your choice should be dictated by the specific thermal hazards you face in your daily work.

- If your primary focus is protection from direct flame or flash fires: Prioritize a boot with a full upper and stitching made from inherently flame-resistant fabrics like Nomex or Kevlar.

- If your primary focus is contact with hot surfaces: Ensure your boot has an HRO-rated outsole, typically made from a high-grade Nitrile rubber compound.

- If your primary focus is overall protection in a varied environment: Look for a boot that balances a heat-resistant sole with other non-negotiable features like a safety toe, puncture resistance, and superior slip resistance.

Understanding these material-driven features empowers you to select footwear that provides a genuine, reliable shield against workplace dangers.

Summary Table:

| Key Component | Material & Feature | Primary Function |

|---|---|---|

| Upper | Nomex, Kevlar, Flame-Retardant Leather | Resists ignition, chars instead of melting |

| Sole | Nitrile Rubber (HRO-rated) | Withstands contact with surfaces up to 300°C (572°F) |

| Stitching/Laces | Nomex or Kevlar Thread | Prevents boot from falling apart under heat exposure |

Need reliable, heat-resistant safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial footwear, including models with advanced heat and flame-resistant features. We can provide the durable, protective footwear your workforce needs to operate safely in extreme environments.

Contact us today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What were some early hazards that safety footwear addressed? A Guide to Essential Foot Protection

- What are some hazards that can cause slips and falls in the workplace? Prevent Costly Injuries & Boost Safety

- What is the difference between side-zip and lace-up security guard safety boots? Speed vs. Perfect Fit

- What are the core safety features of industrial safety shoes? Expert Guide for Bridge & Heavy Machinery Safety