At its core, a modern safety shoe combines style and protection by embedding advanced protective technologies within the framework of conventional shoe designs. This is achieved through the use of low-profile composite or steel components, specialized sole compounds, and construction methods that mirror those used in high-end dress or casual footwear.

The key is strategic integration. Instead of adding bulky guards externally, today’s safety shoes build protection directly into the silhouette, allowing them to meet rigorous safety standards while maintaining a clean, professional appearance.

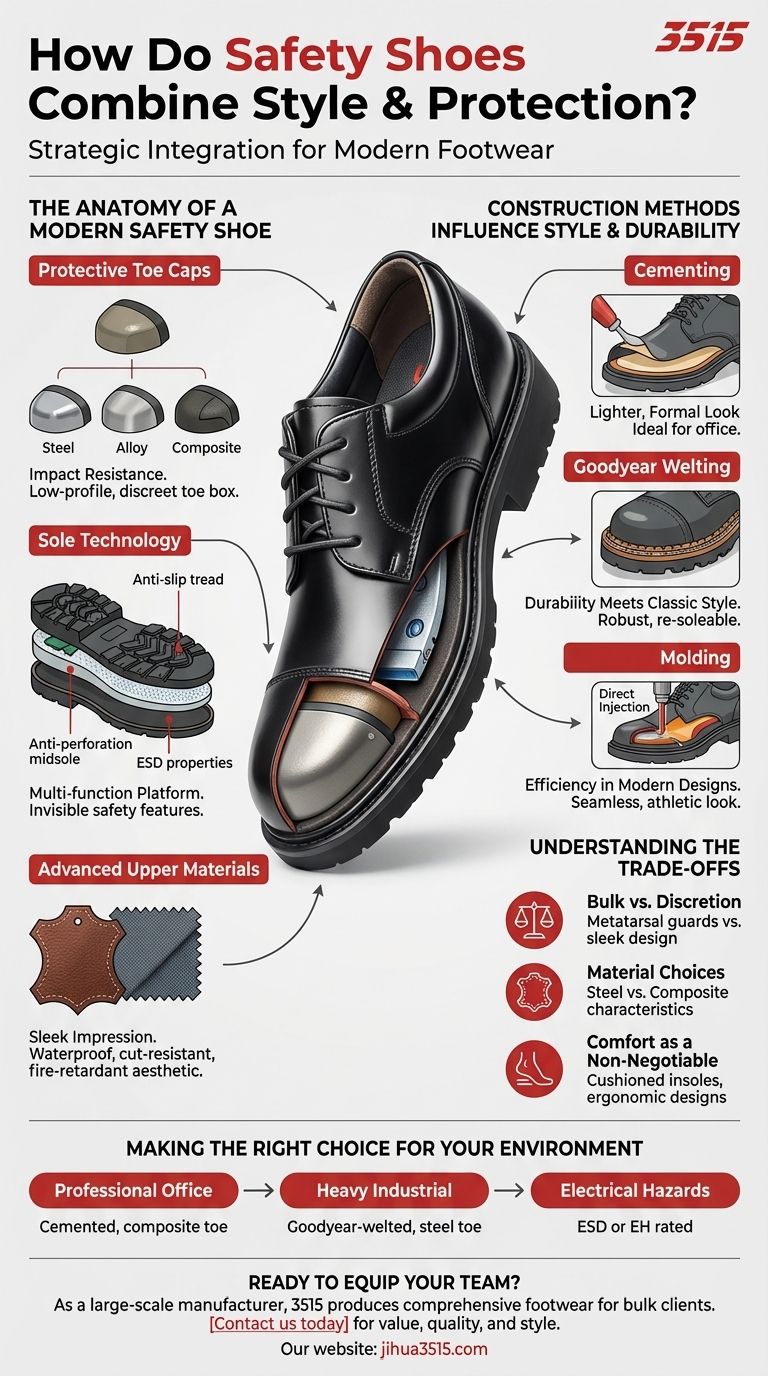

The Anatomy of a Modern Safety Shoe

To understand how safety and style coexist, you must look at the individual components that have been re-engineered for this dual purpose.

Protective Toe Caps: The Core of Impact Resistance

The most critical safety feature is the protective toe cap, which shields the foot from impact and compression hazards.

Modern shoes use steel, alloy, or composite materials. While steel is the traditional standard, lighter composite materials allow for a less bulbous and more discreet toe box, which is essential for achieving a formal or athletic look.

Sole Technology: More Than Just a Foundation

The sole is a multi-function platform that provides stability and specialized protection.

Features like anti-slip treads, anti-perforation midsoles (made of steel or composite fabric), and electrostatic dissipative (ESD) properties are engineered directly into the sole's layers, remaining completely invisible from the outside.

Advanced Upper Materials: A Sleek First Impression

The upper part of the shoe dictates its style. Modern safety footwear utilizes a wide range of materials, from traditional leather for a classic look to advanced textiles for a more athletic appearance.

These materials can also incorporate features like waterproofing, cut resistance, and fire-retardant properties without compromising the shoe's aesthetic.

How Construction Methods Influence Style and Durability

The method used to attach the sole to the upper has a profound impact on both the shoe's final look and its longevity.

Cementing: The Path to a Lighter, Formal Look

In this process, the sole is attached to the upper using a strong adhesive. This is the same method used for many dress shoes and sneakers.

Cementing allows for greater design flexibility, lighter weight, and a sleeker profile, making it ideal for safety shoes intended for office or light-duty environments.

Goodyear Welting: Durability Meets Classic Style

This traditional method involves stitching a leather welt to both the upper and the sole, creating an exceptionally durable and often re-soleable shoe.

Goodyear welting is common in high-end work boots and classic dress shoes, offering a robust aesthetic that signals quality and longevity.

Molding: Efficiency in Modern Designs

Also known as direct injection, this method involves injecting a liquid sole material (like polyurethane) into a mold attached to the shoe's upper.

This creates a seamless, watertight bond and is often used for modern, athletic-style safety shoes and clogs where a clean, integrated look is desired.

Understanding the Trade-offs

While modern technology has narrowed the gap between style and safety, some compromises are inherent.

Bulk vs. Discretion

The highest levels of protection, such as metatarsal guards that protect the top of the foot, will inevitably add bulk and are difficult to conceal in a sleek design. You must match the level of protection to the actual hazard.

Material Choices and Their Limits

Steel toes offer maximum protection in a thin profile but are heavier and conduct temperature. Composite toes are lighter and non-conductive but may need to be slightly thicker to achieve the same safety rating.

Comfort as a Non-Negotiable Feature

A shoe is useless if it's too uncomfortable to wear. Look for features like cushioned insoles and ergonomic designs, as true performance comes from a shoe you can wear safely and comfortably all day long.

Making the Right Choice for Your Environment

Your specific workplace and role should dictate your choice, balancing aesthetics with the necessary protective features.

- If your primary focus is a professional office with required site visits: Choose a cemented shoe with a composite toe for a lightweight, formal appearance that meets safety standards.

- If your primary focus is heavy industrial work with aesthetic standards: A Goodyear-welted boot with a steel toe provides maximum durability and a classic, rugged style.

- If your primary focus is protection from electrical hazards or static buildup: Prioritize shoes with an explicit ESD or Electrical Hazard (EH) rating, as this non-negotiable feature is independent of style.

Ultimately, you no longer have to choose between looking professional and staying protected.

Summary Table:

| Feature | Role in Safety | Role in Style |

|---|---|---|

| Toe Cap (Composite/Steel) | Protects from impact/compression | Enables a low-profile, discreet toe box |

| Sole Technology (Anti-slip, ESD) | Provides grip & electrical safety | Remains invisible; allows for athletic or formal designs |

| Upper Materials (Leather, Textiles) | Can be waterproof, cut-resistant | Defines the shoe's aesthetic (classic or modern) |

| Construction (Cementing, Welting) | Impacts durability and longevity | Determines final profile (sleek or robust) |

Ready to equip your team with safety footwear that combines superior protection with professional style?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered to meet the highest standards without sacrificing aesthetics.

Contact us today to discuss your needs and discover how we can deliver value, quality, and style for your business.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- How do safety shoes and PPE impact thermal comfort? Balance Protection with Thermal Regulation in Workshops

- What are the biomechanical differences between training shoes and professional safety shoes? | Gait Recovery Insights

- What is a metatarsal guard in safety boots? Essential Protection for Your Entire Foot

- How can work shoes help manage plantar fasciitis? Alleviate Heel Pain & Improve Daily Comfort

- What is the strategic market function of high-specification Safety Shoes for footwear distributors? Grow Your Portfolio

- What are the key features of genuine leather work shoes? Understand the Trade-offs for Your Work

- What are the advantages of using professional safety shoes with arch support for sewing operators? Boost Productivity

- What is the function of professional industrial safety shoes in MMH biomechanical experiments? Enhance Data Accuracy