In short, composite toe boots handle extreme temperatures exceptionally well. Because they are made from non-metallic materials like Kevlar, carbon fiber, and plastic, they do not conduct heat or cold. This provides a significant advantage over steel toe boots, which can become uncomfortably hot or dangerously cold by transferring ambient temperatures directly to your foot.

The core reason composite toe boots excel in temperature extremes is their inherent thermal insulation. Unlike metal, the materials used in a composite cap act as a buffer, helping to maintain a stable and comfortable temperature inside the boot regardless of the external environment.

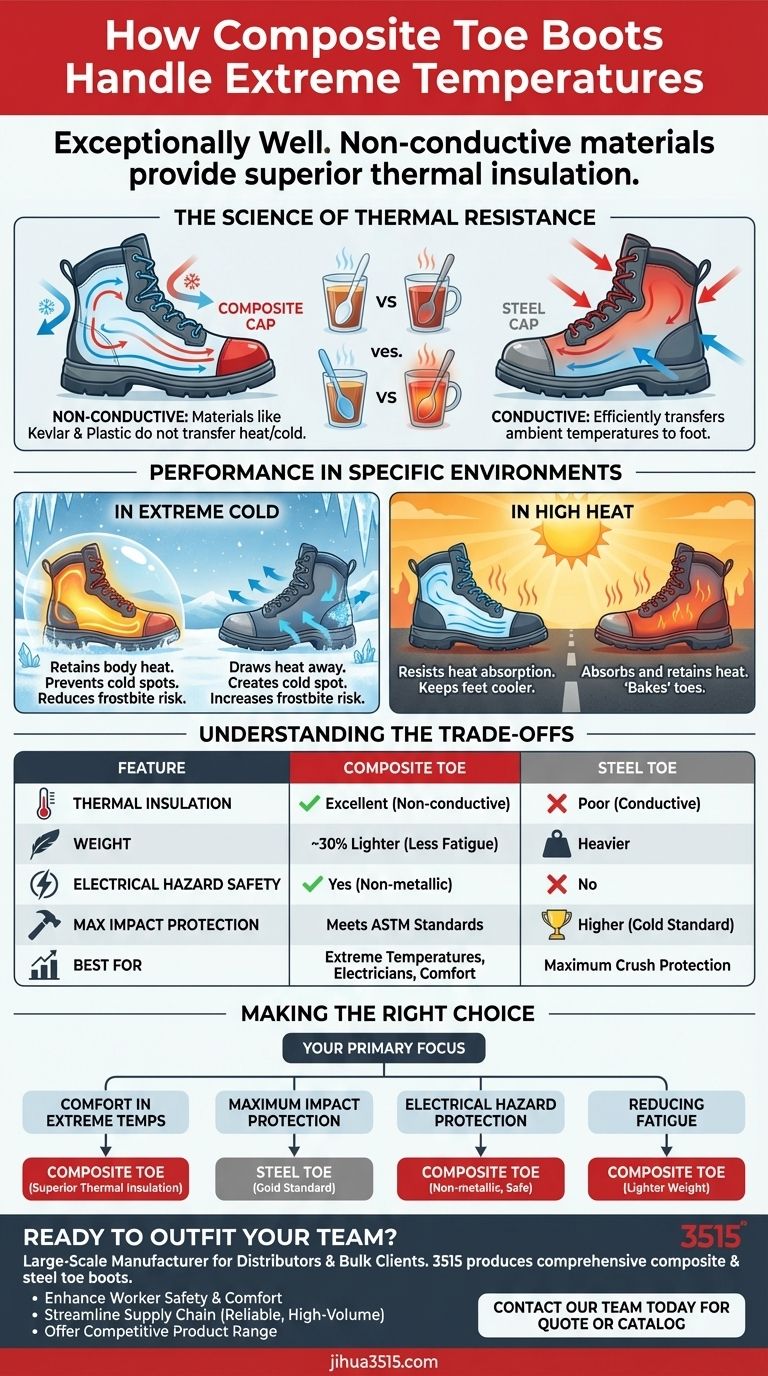

The Science of Thermal Resistance

To understand why composite boots are superior for temperature regulation, you need to look at the fundamental properties of their materials compared to steel.

Non-Conductive by Nature

A composite toe cap is, by definition, made of non-metallic materials. These materials are poor thermal conductors.

Think of it like holding a metal spoon in a hot cup of tea versus a plastic one. The metal spoon quickly becomes hot to the touch, while the plastic spoon remains cool. Steel toe caps behave like that metal spoon, efficiently transferring heat or cold to your toes.

Maintaining a Stable Internal Climate

This lack of thermal conductivity means the composite toe cap doesn't become a heat sink in hot weather or a cold plate in the winter.

It effectively isolates your toes from the ambient temperature, preventing the boot from working against your body's natural temperature regulation. This results in greater comfort and safety during long shifts in demanding conditions.

Performance in Specific Environments

While the principle is the same, the benefit of a composite toe manifests differently in hot and cold weather.

In Extreme Cold

In freezing temperatures, a steel toe cap can actively draw heat away from your foot, creating a significant cold spot and increasing the risk of frostbite.

A composite toe cap does not have this effect. It helps keep the warmth your body generates inside the boot. For truly arctic conditions, however, the composite toe should be paired with dedicated insulation layers for maximum protection.

In High Heat

On hot asphalt or in a sweltering factory, a steel toe can absorb and retain heat, essentially baking your toes.

Composite materials resist this heat absorption. Many boots designed for hot environments also incorporate features like moisture-wicking linings to manage sweat, ensuring your feet stay drier and more comfortable.

Understanding the Trade-offs

While composite toes are the clear winner for temperature management, they are not the superior choice in every single category. Making an informed decision requires understanding the full picture.

Impact Protection

The primary purpose of a safety toe is impact resistance. While composite toes meet all OSHA and ASTM safety standards, steel generally offers a higher level of protection against extreme crushing and impact forces.

Weight and Comfort

Composite toe boots are typically about 30% lighter than their steel counterparts. This reduction in weight significantly reduces foot fatigue over a long workday, making them a more comfortable option for many professionals.

Electrical Hazards

Because they contain no metal, composite toe boots are the default choice for electricians, engineers, and anyone working where they might come into contact with live electrical circuits. They provide crucial electrical hazard protection that steel cannot.

Cost and Durability

Composite toe boots are often more expensive upfront. In terms of durability, while the cap itself is robust, it can be more susceptible to damage after an initial impact and may need to be replaced, whereas steel can often withstand multiple impacts.

Making the Right Choice for Your Environment

Your choice between composite and steel should be dictated by the primary hazards and conditions of your job.

- If your primary focus is comfort in extreme hot or cold temperatures: Composite is the definitive choice due to its superior thermal insulation.

- If your primary focus is maximum impact protection from heavy falling objects: Steel toe remains the gold standard for the highest levels of impact resistance.

- If your primary focus is protection from electrical hazards: Composite is the only appropriate and safe option.

- If your primary focus is reducing fatigue during long shifts: The lighter weight of composite boots provides a clear advantage for all-day comfort.

Choosing the right boot means matching the material's core strengths to the unique demands of your workday.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Thermal Insulation | Excellent (Non-conductive) | Poor (Conductive) |

| Weight | ~30% Lighter | Heavier |

| Electrical Hazard Safety | Yes (Non-metallic) | No |

| Max Impact Protection | Meets ASTM Standards | Higher (Gold Standard) |

| Best For | Extreme Temperatures, Electricians, Comfort | Maximum Crush Protection |

Ready to Outfit Your Team with High-Performance Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite and steel toe boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, ensuring you get the right boots for your specific environmental hazards and comfort needs.

We help you:

- Enhance Worker Safety & Comfort: Provide boots that protect against impacts and temperature extremes.

- Streamline Your Supply Chain: Benefit from reliable, large-volume manufacturing and consistent quality.

- Offer a Competitive Product Range: Access a wide variety of styles and safety features for your market.

Let's discuss your specific requirements. Contact our team today to get a quote or request a catalog!

Visual Guide

Related Products

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- How to choose the right work boot? Match Safety Features to Your Job's Hazards

- Why are PVC work boots a good choice for workplaces with exposure to liquids?

- How have moc toe boots transitioned into modern fashion? From Workwear to Wardrobe Essential

- What are the key components of modern work boots? Engineered for Ultimate Durability and Comfort

- How is all-around comfort achieved in western boots? Discover the Integrated Comfort System

- What are the functions of waterproof work boots and breathable outdoor shoes? Essential Safety for Extreme Construction

- Where can you purchase waterproofing products for leather boots? A Guide to Finding and Applying the Right Product

- What are the characteristics of harness and engineer boots? Defining Two Iconic Rugged Styles