To choose the right work boot, you must first analyze the specific hazards of your work environment. This means identifying potential risks like falling objects, punctures from below, electrical currents, or slippery surfaces. Once you have a clear picture of these dangers, you can systematically match them to certified safety features, materials, and construction types that are designed to mitigate those exact risks.

The most effective way to select a work boot is to stop thinking about the boot itself and start by creating a "risk profile" of your job. The right boot is not the one with the most features, but the one whose features directly neutralize the specific dangers and demands you face every day.

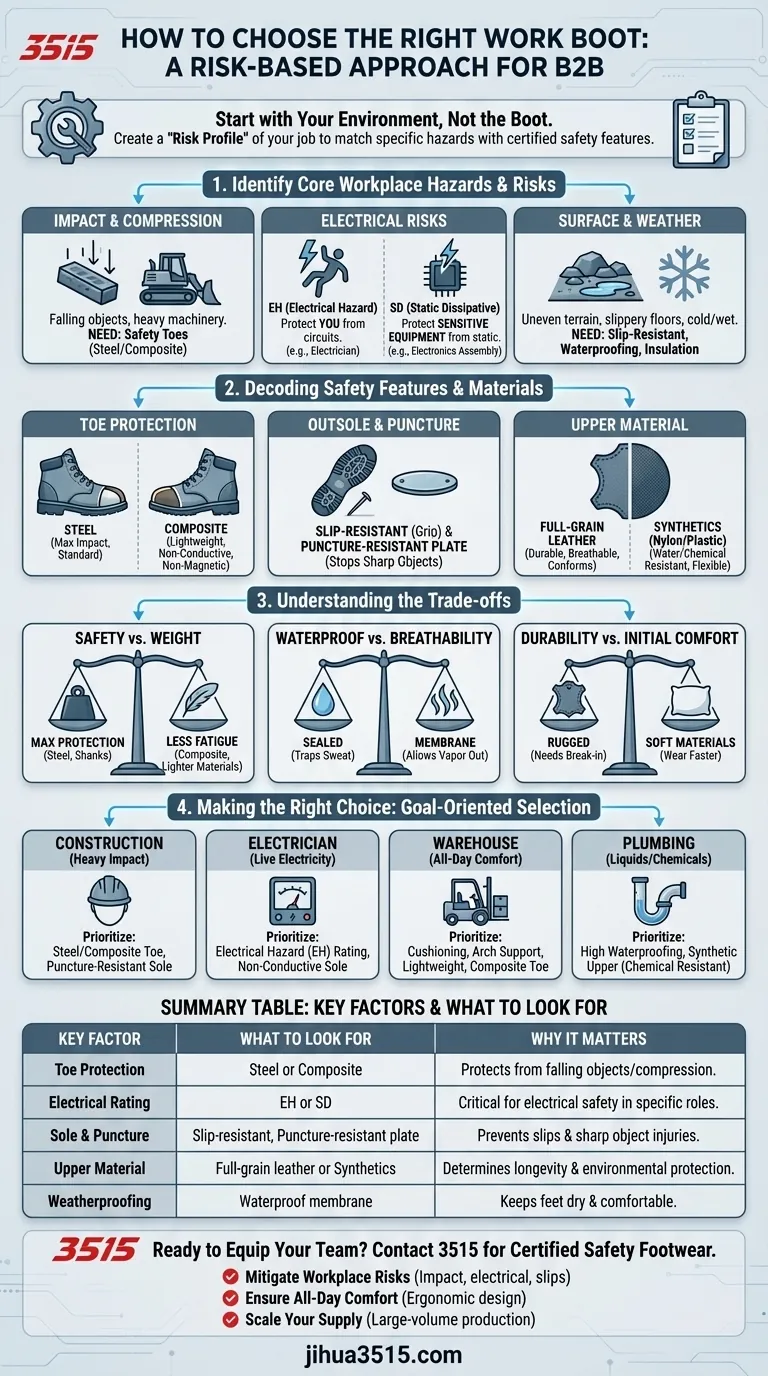

Start with Your Environment, Not the Boot

The most common mistake is choosing a boot based on brand or style. A truly functional work boot is a piece of personal protective equipment (PPE) tailored to your job site.

Identify Core Workplace Hazards

Before looking at any boot, list the potential dangers. Do you work around heavy machinery or materials that could fall and crush your foot? This points to a need for safety toes.

Are you walking on sites where nails, screws, or other sharp objects could be on the ground? This indicates a requirement for puncture-resistant soles.

Assess Electrical Risks

The electrical rating is a critical, and often misunderstood, feature. You must know if you are protecting yourself from electricity or protecting sensitive equipment from yourself.

An Electrical Hazard (EH) rating means the boot is designed to protect you from accidental contact with live electrical circuits. An electrician needs EH-rated boots.

A Static Dissipative (SD) rating means the boot prevents the buildup of static electricity in your body, protecting sensitive electronic components from damage. Someone working in electronics assembly needs SD-rated boots. These two ratings are fundamentally different.

Factor in Surface and Weather Conditions

Consider the surfaces you walk on most often. Uneven terrain, concrete floors, or oily surfaces all demand different types of outsole traction to prevent slips and falls.

Likewise, working in wet or cold conditions necessitates features like waterproofing and insulation to keep your feet dry, warm, and healthy.

Decoding Safety Features and Materials

Once you have your risk profile, you can translate it into specific boot features. The labels and materials on a work boot are a technical language that describes its protective capabilities.

Toe Protection: Steel vs. Composite

The safety toe is the classic feature of a work boot, but the material makes a difference.

Steel toes offer maximum protection against impact and compression and are the traditional standard.

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter than steel, do not conduct heat or cold, and will not set off metal detectors.

Outsole and Puncture Resistance

The outsole determines your grip and durability. Look for slip-resistant properties if you work on slick surfaces.

A puncture-resistant plate is a protective layer built into the midsole to stop sharp objects from penetrating the bottom of the boot. This is essential for construction and demolition sites.

Upper Material: Leather vs. Synthetics

The boot's upper material affects its durability, breathability, and resistance to environmental factors.

Full-grain leather is highly durable, breathable, and conforms to your foot over time, but requires maintenance.

Synthetic materials like nylon and advanced plastics can offer superior water resistance, chemical resistance, and flexibility with less break-in time required.

Understanding the Trade-offs

Choosing a work boot always involves balancing competing priorities. Understanding these compromises is key to finding the right fit for your needs.

Safety vs. Weight

Heavier boots with steel toes, shanks, and thick outsoles offer incredible protection but can lead to foot and leg fatigue over a long shift. Lighter composite-toe boots can reduce this fatigue but may offer slightly less impact resistance.

Waterproofing vs. Breathability

A fully sealed, waterproof boot is excellent for keeping water out, but it can also trap sweat inside. This can lead to discomfort and blisters. Look for boots with a breathable waterproof membrane that allows vapor to escape while blocking liquid from entering.

Durability vs. Initial Comfort

The most rugged, durable boots are often made from thick, stiff leather that requires a significant break-in period. A boot that feels perfectly comfortable out of the box may use softer materials that will not stand up to years of hard use.

Making the Right Choice for Your Goal

Ultimately, your choice should be a direct response to your daily work life. Use your risk profile to guide your final decision.

- If your primary focus is protection from heavy impact (construction, manufacturing): Prioritize a certified steel or composite safety toe and a puncture-resistant sole.

- If your primary focus is working around live electricity (electrician): Ensure your boot has a clear Electrical Hazard (EH) rating and a non-conductive sole.

- If your primary focus is all-day comfort on hard floors (warehouse, logistics): Emphasize excellent cushioning, proper arch support, and a lightweight design, possibly with a composite toe instead of steel.

- If your primary focus is exposure to liquids or chemicals (plumbing, sanitation): Select a boot with a high degree of waterproofing and an upper material, likely synthetic, that can resist chemical corrosion.

Choosing the right work boot is a critical investment in your personal safety and professional performance.

Summary Table:

| Key Factor | What to Look For | Why It Matters |

|---|---|---|

| Toe Protection | Steel (max impact) or Composite (lightweight, non-conductive) | Protects from falling objects and compression. |

| Electrical Rating | EH (protects you) or SD (protects equipment) | Critical for electrical safety in specific roles. |

| Sole & Puncture | Slip-resistant outsole; Puncture-resistant midsole plate | Prevents slips and injuries from sharp objects. |

| Upper Material | Full-grain leather (durable) or Synthetics (water/chemical resistant) | Determines boot longevity and environmental protection. |

| Weatherproofing | Waterproof membrane for breathability and dryness | Keeps feet dry and comfortable in wet conditions. |

Ready to Equip Your Team with the Right Work Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear tailored to the specific hazards of your industry. We provide durable, comfortable, and fully compliant boots for distributors, brand owners, and bulk clients.

We help you:

- Mitigate Workplace Risks: Our boots are engineered with precise safety features to protect against impact, punctures, electrical hazards, and slips.

- Ensure All-Day Comfort: We balance protection with ergonomic design to reduce fatigue and boost productivity.

- Scale Your Supply: With extensive production capabilities for all types of shoes and boots, we meet large-volume demands reliably.

Let's discuss your specific needs and find the perfect safety solution for your workforce.

Contact 3515 today for a consultation

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What are the functional purposes of the cowboy boot's design? Uncover the Engineering Behind the Icon

- What are the key parts of a work boot's exterior? A Guide to Safety & Durability

- What are the features of logger heel work boots? Unmatched Stability for Rough Terrain

- What are some key differences between traditional and modern engineer boots? Choose the Right Style for Your Needs

- What are the alternatives to buying new winter biking boots? Save Money & Stay Warm

- When and by whom were engineer boots first produced? Discover the Origins of an Industrial Icon

- What additional protective footwear feature might be beneficial for construction workers in cold climates? Choose Composite Toe for Superior Warmth

- What are fireman's boots called? Discover Bunker & Turnout Boots for Ultimate Protection