At its core, the value of a Polyvinyl Chloride (PVC) work boot in liquid-heavy environments comes from its material nature and construction. As a non-porous polymer, PVC is inherently waterproof and provides a reliable barrier against a wide range of common industrial liquids, oils, and mild chemicals, ensuring the wearer’s feet remain dry and protected.

The primary advantage of PVC boots is not just the material itself, but their seamless, injection-molded construction. This single-piece design eliminates the stitches and seams that are the most common points of failure for leaks in other types of footwear.

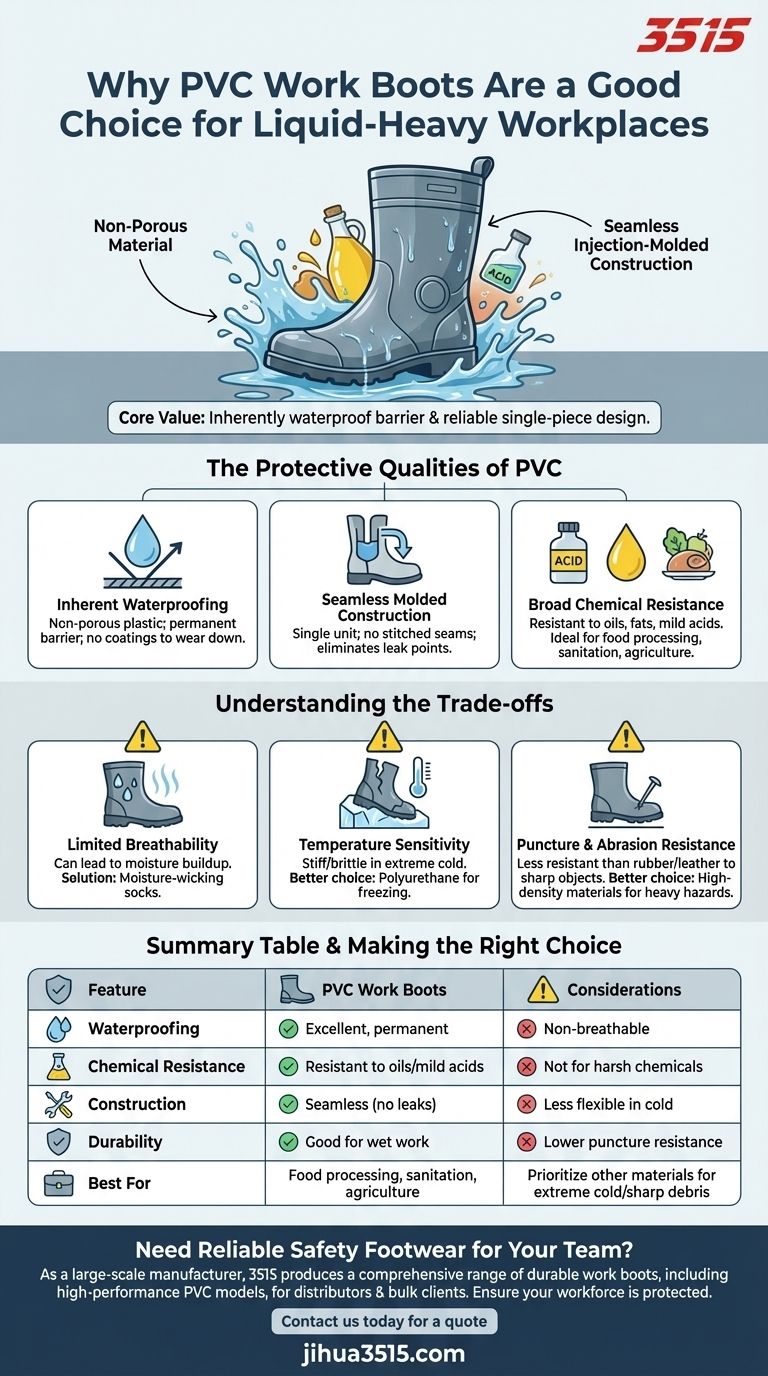

The Protective Qualities of PVC

To understand why PVC is a default choice for many wet-work applications, we need to look at how the boots are made and the properties of the material itself.

Inherent Waterproofing

PVC, a type of plastic, is a non-porous material. Unlike leather or textiles, it does not absorb moisture, providing a complete and permanent barrier against water.

This means its waterproof capability does not rely on temporary coatings or membranes that can wear down or be damaged over time.

Seamless Molded Construction

Most PVC boots are manufactured using an injection molding process. This forces molten PVC into a boot-shaped mold, creating a single, continuous, and seamless unit from top to bottom.

This method is critical because it removes the weakest link in traditional boot construction: the seams. There are no stitched joints between the sole and the upper for water to penetrate, which is a major point of failure in other boot types under constant exposure.

Broad Chemical Resistance

Beyond just water, PVC is resistant to a variety of substances commonly found in industrial and agricultural settings. This includes many acids, fats, oils, and basic chemicals.

This makes them highly suitable for industries like food processing, sanitation, and agriculture where exposure to these types of liquids is a daily occurrence.

Understanding the Trade-offs

While excellent for liquid protection, PVC is not the ideal material for every situation. An objective assessment requires understanding its limitations.

Limited Breathability

The same non-porous quality that makes PVC waterproof also means it is not breathable. This can lead to the accumulation of sweat and moisture inside the boot during long periods of wear.

This can impact comfort and foot hygiene. Using moisture-wicking socks is a common and effective strategy to mitigate this downside.

Temperature Sensitivity

In very cold environments, standard PVC can become stiff and more brittle. This loss of flexibility can make the boots uncomfortable and increases the risk of the material cracking under stress.

For work in freezing temperatures, specialized cold-rated materials like polyurethane or thermo-plastic rubber are often a better choice.

Puncture and Abrasion Resistance

While durable for its intended purpose, PVC does not offer the same level of resistance to punctures, cuts, and heavy abrasion as high-density rubber or premium leather.

In environments with significant physical hazards like sharp debris or rough surfaces, a more robust material may be necessary.

Making the Right Choice for Your Workplace

Selecting the correct boot is a matter of matching the material's strengths to your primary workplace hazards.

- If your primary focus is keeping feet dry from water, mud, and mild chemicals: PVC boots offer an excellent and highly cost-effective solution due to their seamless, waterproof design.

- If your primary focus is working in extreme cold or with harsh chemicals: You should investigate boots made from specialized rubber or polyurethane, which offer better flexibility and resistance in these conditions.

- If your primary focus is all-day comfort with only occasional water exposure: A high-quality, waterproof-treated leather boot may be preferable for its superior breathability.

- If your primary focus is protection against sharp objects and heavy abrasion: Prioritize boots made from thick, high-grade rubber or reinforced materials.

Ultimately, choosing footwear based on a clear understanding of your environment is the foundation of daily safety and comfort.

Summary Table:

| Feature | PVC Work Boots | Considerations |

|---|---|---|

| Waterproofing | Excellent, inherent and permanent | Non-breathable, can lead to sweat buildup |

| Chemical Resistance | Resistant to oils, fats, and mild acids | Not suitable for harsh chemicals |

| Construction | Seamless, injection-molded (no leak points) | Less flexible in extreme cold |

| Durability | Good for general wet work | Lower puncture/abrasion resistance vs. rubber/leather |

| Best For | Food processing, sanitation, agriculture, light industrial | Prioritize other materials for extreme cold or sharp debris |

Need reliable safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable work boots, including high-performance PVC models, for distributors, brand owners, and bulk clients. We ensure your workforce is protected with footwear tailored to your specific liquid exposure hazards.

Contact us today for a quote and discover how our production capabilities can meet your safety and procurement needs.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What should be considered when choosing moc toe boots for casual wear? Find Your Perfect Fit & Style

- Which occupations typically prefer steel toe boots? Essential Safety for High-Risk Jobs

- Why were traditional leather conditioners ineffective for firefighter boots? The Hidden Danger of Sealing vs. Breathing

- What is the difference between cowboy boots and Western boots? Choose the Right Boot for Your Needs

- What are the key characteristics of western work boots? The Ultimate Guide to Style & Safety

- What are insulated boots, and who should use them? Your Guide to Choosing the Right Warmth

- What are the properties of TPU soles for work boots? Superior Durability & Lightweight Performance

- What are the key components of modern work boots? Engineered for Ultimate Durability and Comfort