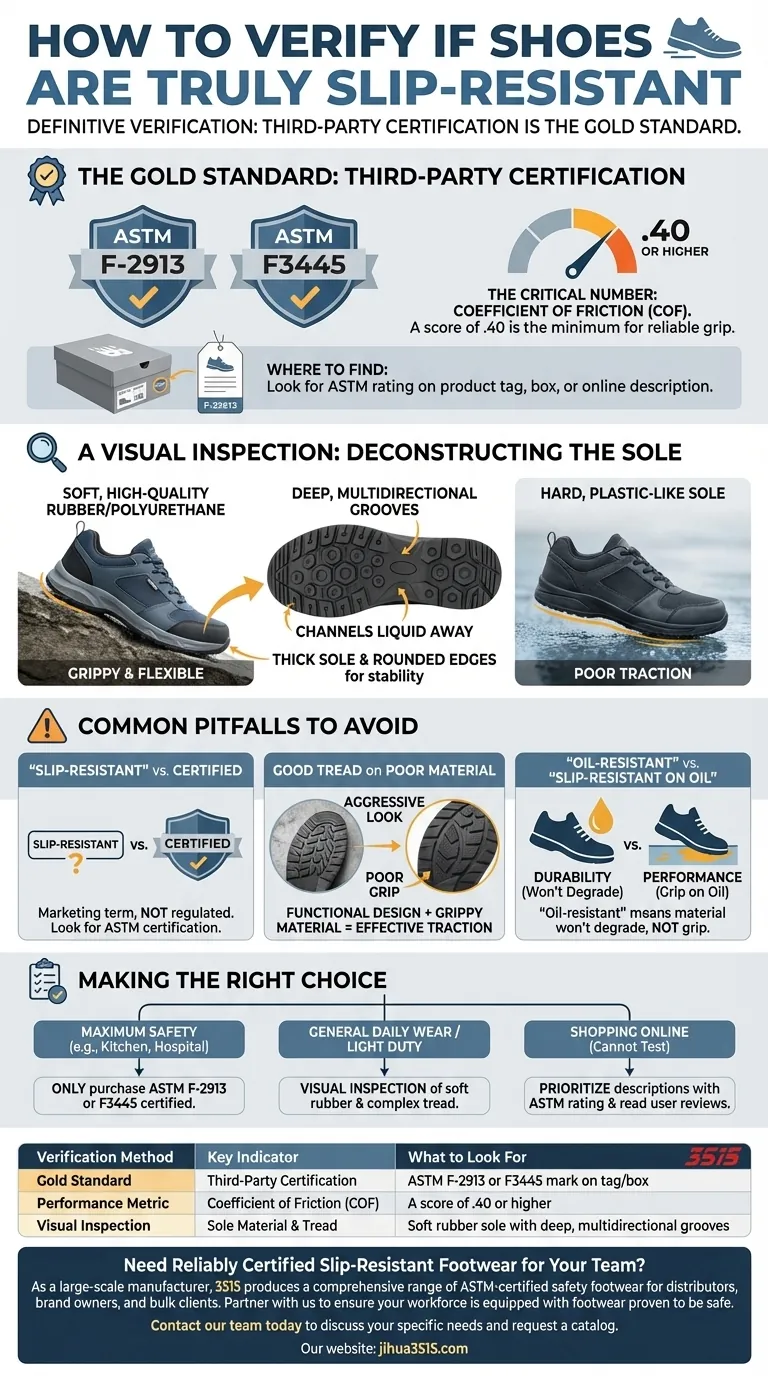

To definitively verify if a shoe is slip-resistant, you must look for proof of third-party certification. The most reliable indicator is a marking of compliance with an industry standard, such as ASTM F-2913 or F3445, which confirms the shoe has passed rigorous testing on various surfaces.

True slip resistance is a technical specification, not a marketing term. While visual cues like tread pattern and material are helpful, the only way to be certain of performance is to verify that the shoe meets or exceeds established safety standards.

The Gold Standard: Third-Party Certification

The most objective measure of a shoe's performance is independent testing. A manufacturer's claim is one thing; a certified rating is proof.

Understanding ASTM Standards

The American Society for Testing and Materials (ASTM) sets the technical standards for safety footwear in the United States. Key standards to look for are ASTM F-2913 or the newer ASTM F3445.

These certifications mean the shoe was professionally tested under controlled conditions on various wet and contaminated surfaces.

The Critical Number: Coefficient of Friction

To pass the ASTM F-2913 test, a shoe must achieve a coefficient of friction of .40 or higher. This number quantifies the shoe's grip.

Think of it as a grade. A score of .40 is the minimum passing grade for reliable slip resistance in professional environments.

Where to Find This Information

Manufacturers who invest in certification will advertise it. Look for the ASTM rating on the product tag, the box, or in the shoe's official online description.

A Visual Inspection: Deconstructing the Sole

If certification information isn't available, you can perform a visual inspection to gauge the likelihood of slip resistance. These features are common in high-performing shoes.

The Material Matters

The sole itself should be made of a soft, high-quality rubber or polyurethane. These materials remain flexible and grippy, conforming to microscopic imperfections in the floor.

Hard, plastic-like soles offer very poor traction on wet or greasy surfaces.

Decoding the Tread Pattern

An effective tread is not just for show; it's designed to channel liquid away from the point of contact. Look for an intricate pattern of deep, multidirectional grooves.

Small shapes like hexagons, circles, or squiggly lines create more biting edges and help maintain grip by dispersing fluids like water and oil.

Sole Shape and Thickness

A thicker sole provides a more stable platform and better durability. Also, look for slightly rounded edges on the bottom of the sole, which help the shoe maintain contact with the ground during movement.

Common Pitfalls to Avoid

Understanding the difference between marketing and engineering is crucial for safety. Be aware of these common points of confusion.

"Slip-Resistant" vs. Certified

The term "slip-resistant" is not legally regulated. Any brand can use it. Without a specific ASTM certification to back it up, the claim is unverified.

Good Tread on Poor Material

An aggressive-looking tread pattern made from a hard, low-quality material will not provide good grip. The combination of a soft, grippy material and a functional tread design is what creates effective traction.

Confusing "Oil-Resistant" with "Slip-Resistant on Oil"

"Oil-resistant" typically means the shoe's outsole material will not degrade, break down, or be damaged by contact with oil. This is a durability feature, not a guarantee of performance on an oily surface.

Making the Right Choice for Your Environment

Your final decision should be based on your specific safety needs and work environment.

- If your primary focus is maximum safety in a professional setting (e.g., kitchen, hospital): Only purchase shoes that explicitly state they meet or exceed ASTM F-2913 or F3445 standards.

- If you're evaluating shoes for general daily wear or light-duty work: A visual inspection of a soft rubber sole with a complex, liquid-channeling tread is a reliable indicator of good performance.

- If you are shopping online and cannot test them: Prioritize product descriptions that list an ASTM rating and read reviews from users who work in environments similar to yours.

Ultimately, verifying a shoe's slip resistance is about trusting certified data over ambiguous claims.

Summary Table:

| Verification Method | Key Indicator | What to Look For |

|---|---|---|

| Gold Standard | Third-Party Certification | ASTM F-2913 or F3445 mark on tag/box |

| Performance Metric | Coefficient of Friction (COF) | A score of .40 or higher |

| Visual Inspection | Sole Material & Tread | Soft rubber sole with deep, multidirectional grooves |

Need Reliably Certified Slip-Resistant Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified shoes and boots designed to meet the highest safety standards.

Partner with us to ensure your workforce is equipped with footwear that is proven to be safe.

Contact our team today to discuss your specific needs and request a catalog of our certified products.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What is the difference between non-slip and slip-resistant shoes? The Truth About Safety Footwear

- What are the best shoes when you're on your feet all day? Find the Perfect Fit for All-Day Comfort

- How can ice grips improve shoe traction on icy surfaces? Prevent slips with mechanical grip.

- What additional benefits do slip-resistant shoes offer besides safety? Boost Productivity & Professionalism

- Why are standardized anti-slip work shoes required in biomechanical research? Ensuring Data Accuracy in Slip Studies

- What are the key features of the best work shoes for women? Find the Perfect Fit for Your Job

- How do athletic shoes with non-slip features differ from regular ones? Discover the Grip Advantage

- What features do reviewers highlight about men's non-slip shoes? Key Traits for Safety & Comfort