At their core, ice grips improve shoe traction by creating a mechanical connection with the icy surface. Unlike the smooth, flat soles of typical footwear that slide on the thin layer of water present on ice, these accessories use aggressive elements like metal studs or steel coils to physically dig into and anchor your foot, preventing dangerous slips.

The fundamental problem with walking on ice is that the pressure from your shoe melts a microscopic layer of it, creating a near-frictionless lubricant. Ice grips solve this by using hard, sharp points to penetrate this water layer and bite directly into the solid ice below.

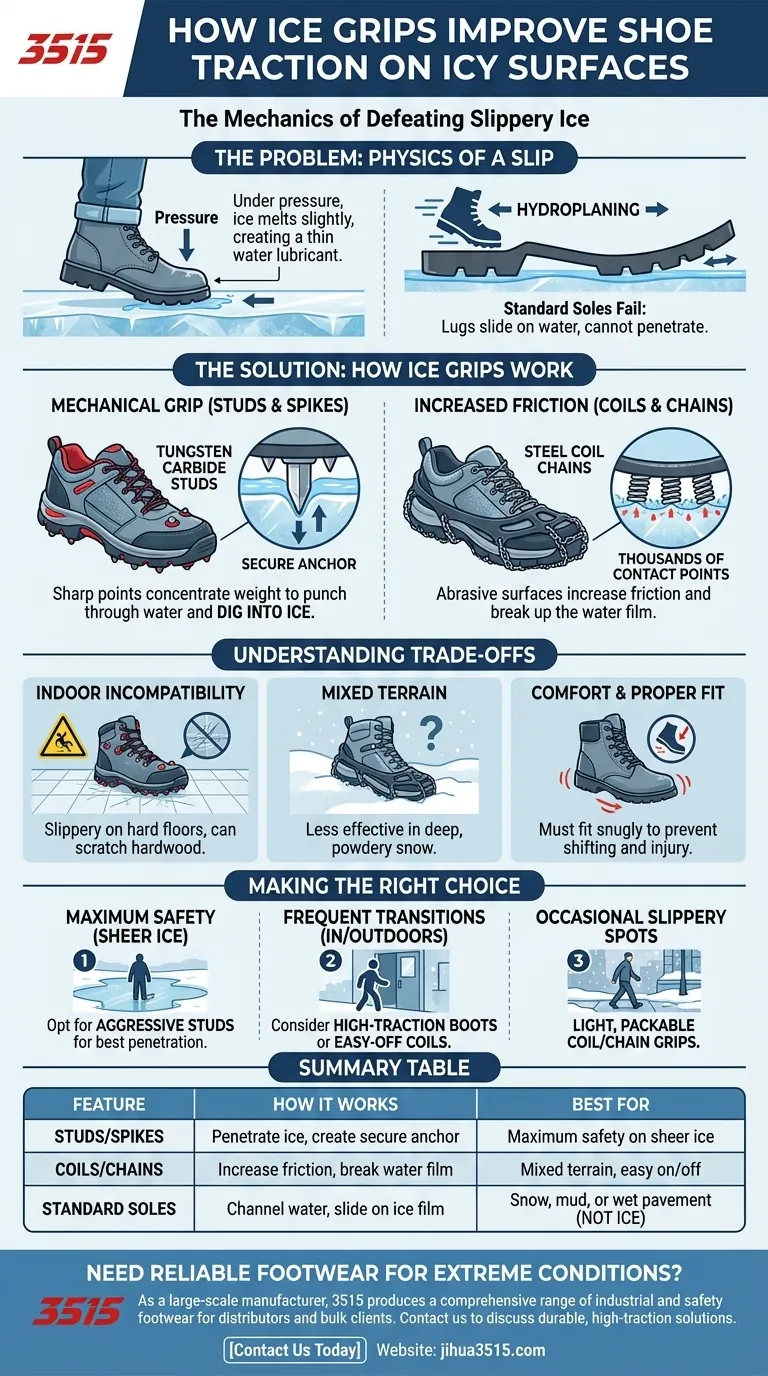

The Physics of a Slip

Why Ice is So Slippery

Under the pressure of a footstep, the melting point of ice decreases slightly. This creates an incredibly thin, invisible film of liquid water between your shoe and the solid ice.

This water layer acts as a lubricant, dramatically reducing the coefficient of friction. Standard rubber or polymer shoe soles simply cannot generate enough grip to overcome this effect, causing them to hydroplane and slip.

The Failure of Standard Soles

Most footwear, even boots with deep lugs, is designed for traction on snow, mud, or wet pavement. Their rubber compounds and tread patterns are meant to channel away water or grip uneven terrain.

On a flat, icy surface, these features are largely ineffective. The broad, flat surfaces of the lugs cannot penetrate the ice, leaving them to slide on the lubricating water film.

How Ice Grips Counteract the Problem

Mechanical Grip via Studs and Spikes

The most effective ice grips feature small, hard spikes or studs, often made from durable materials like tungsten carbide.

These sharp points concentrate all your body weight onto tiny areas. This immense pressure allows them to easily punch through the slippery water layer and dig into the solid ice structure underneath, creating a secure anchor with every step.

Increased Friction via Coils and Chains

Other designs use steel coils or chains that wrap around the bottom of your shoe. While they don't penetrate as deeply as studs, they serve a different purpose.

These abrasive metal surfaces create thousands of small, high-pressure contact points. This design significantly increases surface friction and helps break up the water film, providing a much better grip than a flat rubber sole.

Understanding the Trade-offs

Indoor Incompatibility

The primary drawback of aggressive ice grips, particularly studded models, is their performance indoors. The metal studs that grip so well on ice become extremely slippery on hard, smooth surfaces like tile, concrete, or linoleum.

Furthermore, they can easily scratch and permanently damage hardwood floors, making it essential to remove them before going inside.

Effectiveness on Mixed Terrain

Ice grips are highly specialized. They excel on sheer ice and hard-packed snow but can feel awkward or less effective in deep, powdery snow, where the deep lugs of a dedicated winter boot are more important.

Comfort and Proper Fit

For an ice grip to work, it must fit your shoe snugly. A loose grip can shift underfoot, reducing its effectiveness and potentially creating an unstable platform that could lead to a twisted ankle.

Making the Right Choice for Your Situation

Choosing the right traction aid depends entirely on your specific environment and needs.

- If your primary focus is maximum safety on sheer ice: Opt for ice grips with aggressive tungsten carbide studs that can securely penetrate the slickest surfaces.

- If you frequently transition between icy outdoors and clean indoor floors: Consider dedicated winter boots with high-traction rubber soles, or a more subtle, easily removable coil-style grip.

- If your concern is occasional slippery spots on a daily commute: A light, packable pair of coil or chain grips that you can easily slip on and off is the most practical solution.

Ultimately, understanding how these tools function allows you to take definitive control of your safety in treacherous winter conditions.

Summary Table:

| Feature | How It Works | Best For |

|---|---|---|

| Studs/Spikes | Sharp points penetrate ice, creating a secure anchor. | Maximum safety on sheer ice. |

| Coils/Chains | Abrasive surfaces increase friction, breaking the water film. | Mixed terrain, easy on/off for commutes. |

| Standard Soles | Rubber lugs channel water but slide on ice's lubricating film. | Snow, mud, or wet pavement (not ice). |

Need reliable footwear for extreme conditions?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots built for challenging environments.

Contact us today to discuss your footwear needs and discover how we can provide durable, high-traction solutions for your market.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Lightweight Breathable Sneakers with Wet-Traction Grip for Wholesale & Private Label

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What should you consider when choosing slip-resistant shoes? Ensure Maximum Safety and Comfort

- What are the primary advantages of using wearable IMUs for work posture stability? Enhance Safety with Portable Data

- Who can benefit from wearing non-slip shoes? Essential Safety for Work, Outdoor, and Daily Life

- What industry standards should non-slip shoes comply with? Ensure Workplace Safety with ASTM F2913

- How can you test the arch support of slip-resistant shoes? The Simple Bend Test for All-Day Comfort

- How does a whole-shoe portable bio-simulated mechanical slip tester provide superior performance characterization?

- How can you identify slip-resistant shoes? Look for ASTM Certification & Key Features

- What is the technical function of five-star GRIP rated footwear? Maximize Safety with Advanced Traction Engineering