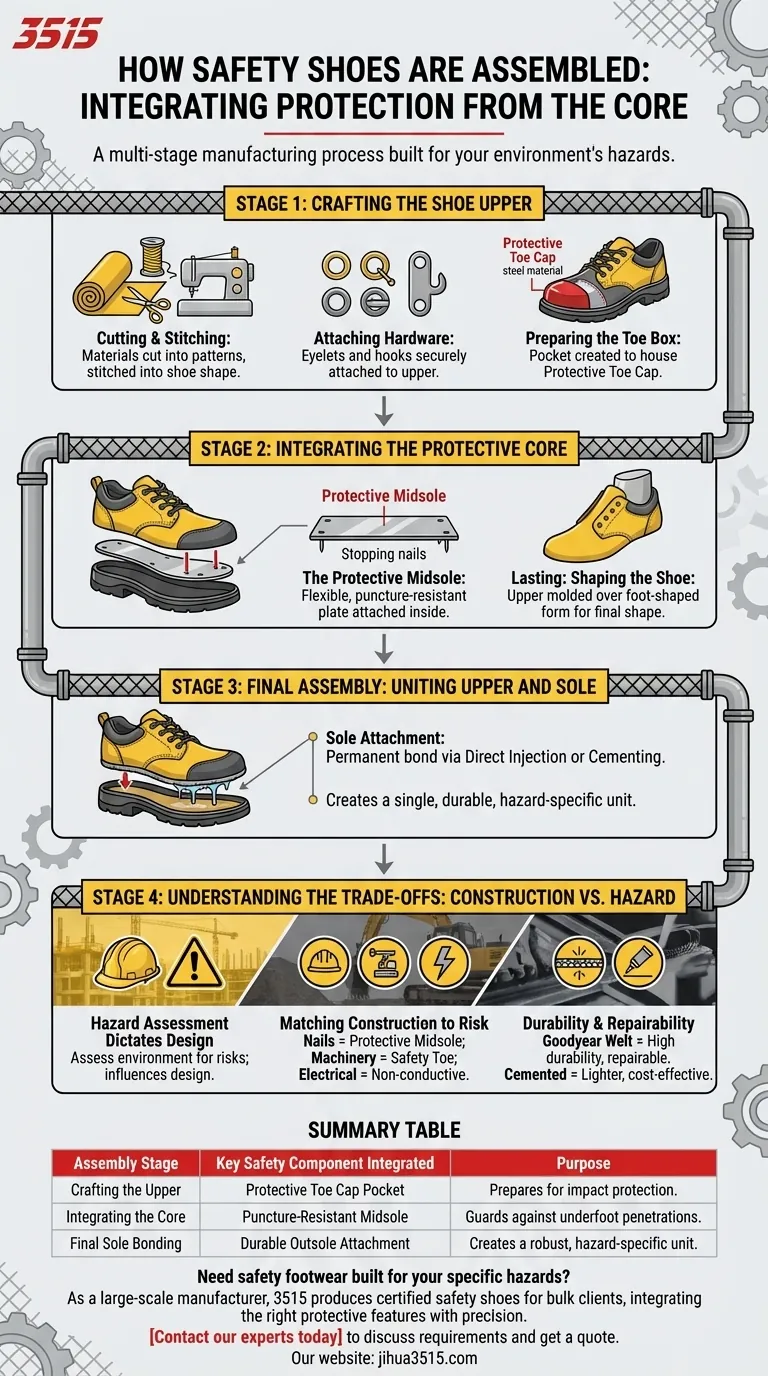

At its core, safety shoe assembly is a multi-stage manufacturing process that integrates protective components into the fundamental structure of a shoe. The process begins by sewing cut materials to form the shoe's upper, attaching necessary hardware like eyelets, and then systematically incorporating critical safety features like a protective midsole before the upper is permanently joined to the outsole.

The key to understanding safety shoe construction is realizing that protection is not an afterthought. Critical safety elements are built directly into the shoe during specific assembly phases, a process guided entirely by the intended work environment's hazards.

The Foundation: Crafting the Shoe Upper

The assembly process begins by creating the main body of the shoe, known as the upper. This initial stage is similar to that of standard footwear but includes preparations for safety-specific hardware.

Cutting and Stitching

First, the primary materials for the upper, such as leather or advanced synthetic fabrics, are cut into precise patterns. These individual pieces are then stitched together by industrial sewing machines to form the recognizable shape of the shoe.

Attaching Hardware

If the shoe design includes laces, this is the stage where metal or composite eyelets and hooks are securely attached to the upper. This ensures they are anchored firmly into the material before final assembly.

Preparing the Toe Box

The toe area of the upper is specially prepared. This involves creating a pocket or structure to house the protective toe cap (often made of steel, aluminum, or a composite material), which is a non-negotiable component for impact protection.

Integrating the Protective Core

With the upper formed, the focus shifts to integrating the components that provide protection from hazards beyond direct impact. This is where a safety shoe's construction truly diverges from that of a standard shoe.

The Protective Midsole

For footwear designed to guard against punctures from below, a protective midsole is attached. This flexible but puncture-resistant plate is positioned inside the sole structure to stop sharp objects like nails from penetrating the shoe.

Lasting: Shaping the Shoe

The completed upper is then stretched and molded over a foot-shaped form called a "last." This crucial step, known as lasting, gives the shoe its final shape and prepares it for the permanent attachment of the sole.

Final Assembly: Uniting Upper and Sole

The final major stage is to permanently bond the prepared upper to the outsole, creating a single, durable unit.

Sole Attachment

Several methods can be used to attach the sole, with the choice often depending on the shoe's intended use and durability requirements. Common techniques include direct injection molding, where the sole is molded directly onto the upper, or cementing, which uses strong industrial adhesives.

Understanding the Trade-offs: Construction vs. Hazard

The specific assembly methods and materials used are not arbitrary. They represent a series of deliberate choices made to counter specific workplace dangers.

Hazard Assessment Dictates Design

As noted in safety program guidelines, the first step is always to assess the work environment for potential foot hazards. This assessment directly influences the shoe's design and assembly.

Matching Construction to Risk

A job site with discarded nails demands a shoe built with a protective midsole. An environment with heavy machinery requires an integrated safety toe. The presence of electrical risks necessitates specific non-conductive materials and cements during the sole attachment phase.

Durability and Repairability

More complex assembly methods, like a Goodyear welt where the upper and sole are stitched together, offer greater durability and repairability. Simpler cemented constructions may be lighter but often cannot be resoled, representing a trade-off between cost and lifespan.

Making the Right Choice for Your Goal

Understanding the assembly process empowers you to select footwear based on its construction, not just its appearance.

- If your primary focus is impact protection: Verify that the shoe is built with a certified safety toe that was integrated during the lasting process, ensuring it's a core part of the structure.

- If your primary focus is puncture protection: Confirm the construction includes a protective midsole that has been bonded or stitched between the insole and the final outsole.

- If your primary focus is longevity in demanding conditions: Consider shoes with stitched or welted construction, as these assembly methods typically offer a more robust bond between the upper and sole.

Knowing how a safety shoe is put together reveals that true protection is fundamentally engineered from the inside out.

Summary Table:

| Assembly Stage | Key Safety Component Integrated | Purpose |

|---|---|---|

| Crafting the Upper | Protective Toe Cap Pocket | Prepares for impact protection. |

| Integrating the Core | Puncture-Resistant Midsole | Guards against underfoot penetrations. |

| Final Sole Bonding | Durable Outsole Attachment | Creates a robust, hazard-specific unit. |

Need safety footwear built for your specific hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures every pair is assembled with precision, integrating the right protective features—from steel toes to puncture-resistant midsoles—for your workforce's safety and comfort.

Contact our experts today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What is the importance of choosing the right size for steel toe boots? Avoid Injury and Boost Productivity

- What types of safety toe boots are available? Find the Perfect Fit for Your Job's Hazards

- What are the consequences of not wearing safety shoes? Protect Your Feet from Severe Workplace Injuries

- What causes corns in steel toe boots and how can they be prevented? Master the Perfect Fit to Avoid Pain

- Are steel toe boots inherently bad for your feet? Debunking Myths for Workplace Safety